Scroll to:

Ensuring Occupational Safety at Railway Transport Operation by Upgrading the Systems of Vibration Damping Plates and Rail Plates

https://doi.org/10.23947/2541-9129-2023-1-39-46

Abstract

Introduction. Noise and vibration in railway transport is a dangerous type of pollution for both the workers and the environment. It is important to carry out a comprehensive analysis of the effects of noise and vibration pollution on railway transport workers, the environment, and to consider available methods to minimize harmful effects created during the movement of trains. Safety can be achieved by ensuring regulatory noise and vibration levels.

The work objective is to assess the safety of work during the operation of railway transport by improving the system of vibration damping pads and rail plates.

Materials and Methods. In the course of the study, an analysis of the occurrence of noise and vibration, an assessment of their negative impact on railway transport workers and the environment was carried out. The available methods of noise pollution minimization are considered, the classification of noise and vibration control methods is described. The methods and means required by the regulatory documents on labor safety during the operation of railway transport were used in the work.

Results. Based on the results of the study, it follows that there is a need to strengthen measures for comprehensive protection and minimization of harmful factors. The result of the study was the proposal to improve one of the applied methods of noise minimization — the installation of a vibration damping pad, for the production of which secondary raw materials in the form of rubber crumbs are used. The paper calculates the economic efficiency of one of the proposed methods of minimizing noise pollution and describes the positive effect after its application, considers available options for improving the sound absorption of rails.

Discussion and Conclusion. Based on the results of the study, the positive economic effect of one of the proposed ways to improve the noise minimization method was revealed.

Keywords

For citations:

Golovina E.I., Sokolov D.A. Ensuring Occupational Safety at Railway Transport Operation by Upgrading the Systems of Vibration Damping Plates and Rail Plates. Safety of Technogenic and Natural Systems. 2023;(1):39-46. https://doi.org/10.23947/2541-9129-2023-1-39-46

Introduction. Comprehensive analysis of noise and vibration pollution from railway transport shows a long-term negative impact on human health [1]. This effect is dangerous due to the occurrence of various diseases — vibration disease, diseases of the auditory nerve (neuritis, auditory dissynchrony) [2]. The share of noise in the factor assessment of the working conditions of drivers and assistant drivers of locomotives is more than 35% [3]. When conducting a special assessment of working conditions, the degree of harmfulness and danger under the action of vibroacoustic factors is established according to R 2.2.2006–05, taking into account their temporary characteristics (constant, non-constant noise, vibration, etc.)1. Creation of a comfortable working environment for people working in railway transport is achieved by minimizing the impact of such factors.

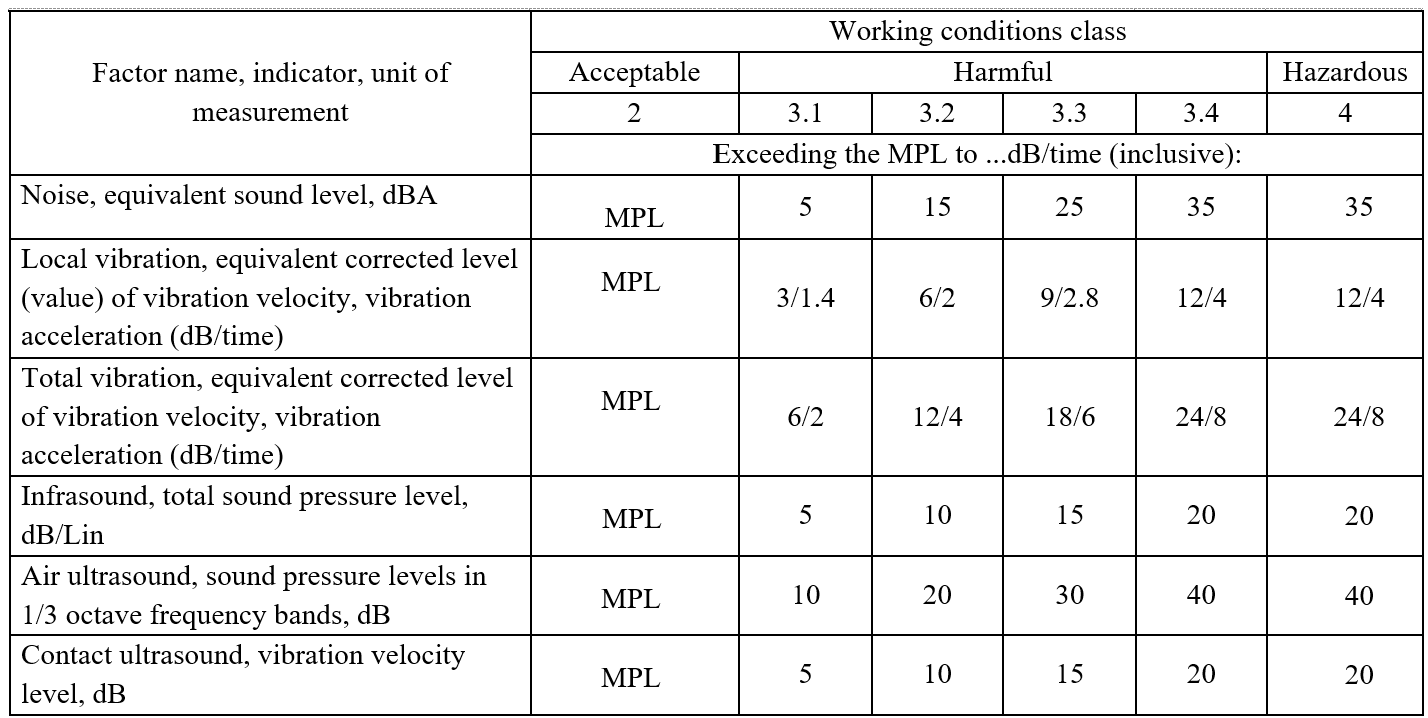

When assessing the impact of noise pollution and vibration within the framework of a special assessment of working conditions, a consistent methodology is used, which includes: identification of factors that negatively affect workers; research and measurement of factors; attribution of working conditions to a certain class, based on the degree of harmfulness [4]. When assessing working conditions, attention is paid to the nature of noise (constant or non-constant) and its tone characteristics. When an employee is exposed to constant noise, the assignment of working conditions to a class or subclass under the influence of vibroacoustic factors is carried out based on the measurement results of sound pressure levels in octave ranges with average geometric frequencies 31.5; 63; 125; 250; 500; 1000; 2000; 4000; 8000 Hz (Table 1) [5].

Table 1

Working conditions classes depending on noise levels, local, general vibration, infra- and ultrasound in the workplace according to R 2.2.2006–052

Working conditions assessment by vibroacoustic factors at the workplaces of drivers and assistant drivers, track and station workers is carried out similarly to stationary workplaces where there is equipment that is a source of noise and vibration. The maximum permissible noise levels in the workplace are determined taking into account the severity and intensity of work activity according to SN 2.2.4/2.1.8.562–963.

The work objective is to assess the safety of work during the operation of railway transport by upgrading the systems of vibration damping plates and rail plates.

The main source of noise in railway transport is the noise emitted by the train during movement, which is created by track machines and technical equipment [1]. Vibration is transmitted from the wheelsets to the body of the car and tends to spread into the environment [5]. Increased noise and vibration are considered to be the criteria, the compliance of which with regulatory values is technically the most difficult to achieve [6].

The results of long-term clinical observations and examinations of large groups of people of various specialties, whose work is associated with exposure to intense noise, allow us to consider noise sickness an independent form of professional pathology4. Noise regime, which significantly exceeds the standards, with continuous exposure has a negative effect on health: the hearing organs, nervous and vegetative systems suffer [7]. Noise level from railways depends on many factors. This is influenced, for example, by the technical condition of the tracks and rolling stock, the type of brakes used, the volume of traffic or the terrain. Carriage and repair and equipment depots, which are located near residential areas, cause significant harm to human health and the integrity of natural systems. Noise and vibration that occur during the movement of trains also harm humans and the environment. A significant excess of noise level standards brings discomfort to residents, can be a significant cause of deterioration of well-being and decreased performance. Prolonged and systematic exposure to noise pollution and vibration can be the beginning of the development of diseases of the nervous and vegetative-vascular systems. The number of people exposed to a high degree of sleep disturbance is very large. Most people are exposed to constant noise of 50-60 dB at night, which in the absence of other daytime noise sources is one of the main factors of insomnia and systematic neuroses.

In noise minimization methods classification, the following directions are used: minimizing or eliminating noise at the source, minimizing noise from the source to the object (sound insulation, sound absorption, minimization) and protecting people with special means. Noise protection can be implemented by means of collective protection (acoustic screens, fences, casings, vibration damping pads), or by means of individual protection (overhead headphones, earplugs).

Materials and Methods. Current methods of noise control are technical methods (timely maintenance of equipment and railway tracks, grinding rails, etc.), architectural planning and acoustic methods (installation of noise shields, casings, vibration damping plates).

To date, there are many alternative methods that contribute to noise exposure reduction through the use of additional technical solutions: highly elastic gaskets for rail fasteners, ballast mats, elastic supports for the track on plates with a ballast tank, systems called "mass-spring". Mass-spring systems are used when presenting the most stringent requirements for protection against structural noise and in the presence of constructive implementation possibilities.

The results of theoretical studies have shown the effectiveness of the "mass-spring" design scheme. The most effective structures are those that contain monolithic concrete or concrete elements [8]. When designing an elastic support for mass-spring systems, the chosen design solution determines the final efficiency of the vibration insulation system.

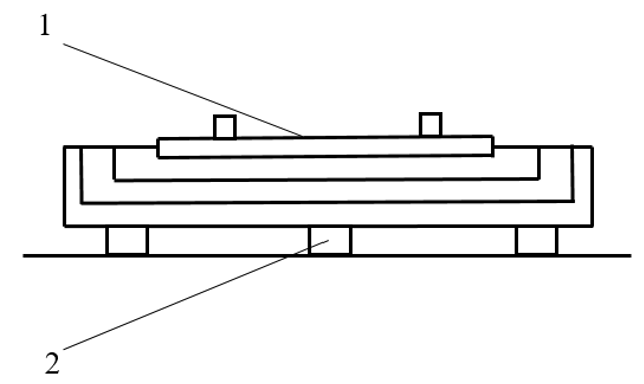

Let us consider the actual constructive methods of noise control in more detail. A belt support, as a type of construction, is used in "mass-spring" systems (Fig. 1). The main advantage of such a support is effective vibration compensation that occurs during train movement due to the relatively large area of the bases. With the introduction of a belt support, it is possible to obtain a reduction in the frequencies of the upper structure of the track that negatively affect a person with long-term exposure at a lower cost. The positive effect is the reduction of vibration and noise.

Fig. 1. Variant of belt supports installation scheme: 1 — railbed; 2 — belt supports

The materials used in the mass-spring system must have a number of properties: resistance to short-term, peak loads, have a fine-mesh, static structure, which makes it possible to maintain the useful efficiency of the supports during operation.

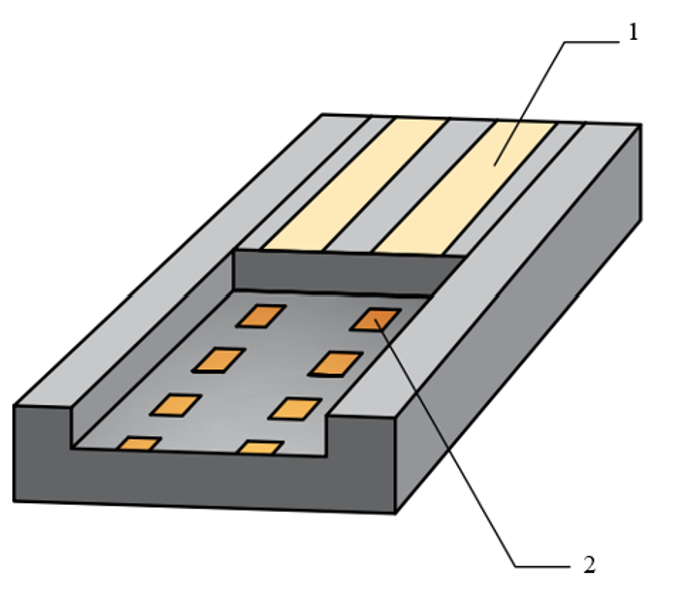

Point supports can only be used with a specific design. Slabs of monolithic concrete are lifted; the supports are installed through special mounting holes (Fig. 2). It is worth noting that the support area is extremely small, when designing supports of such a design, it is necessary to take into account the horizontal forces that arise during the movement of the train. To limit horizontal shifts in accordance with the specified parameters, it is necessary to find the optimal ratio between the shear modulus, the elasticity of the material, the thickness and the area of the support.

Fig. 2. Variant of point support installation scheme: 1 — railbed; 2 — point supports

After installation, point supports can provide protection against structural noise and reduce natural frequencies. The use of such systems makes it possible to achieve noise minimization up to 30 dB or more. The main difficulty in using this method is a complicated installation, depending on the design of the plates, the high cost of installation and routine maintenance.

One of the effective and relatively low-cost methods of noise reduction from the "wheel-rail" system in the source is to reduce the sound emission of the rail. This is achieved by installation of vibration damping plates [1].

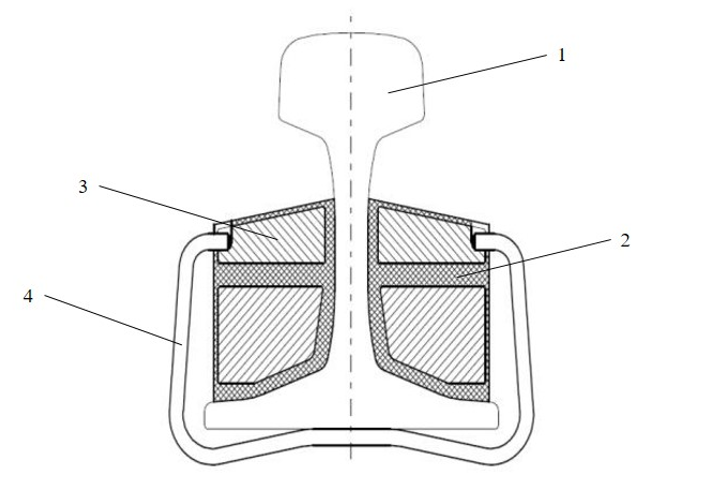

The vibration damping plate is an overlay that is installed on rails to absorb noise. Their advantage is that they prevent the spread of noise to the surrounding area. Due to their structural composition, they absorb vibrations arising in the "wheel-rail" system, and thereby prevent the formation of noise in the rail. In case of train movement, when the wheel comes into contact with the rail, noise with a variable spectrum is generated. The rail damper operates according to the vibration absorption system at frequencies with the highest noise level. Fig. 3 provides one of the variants of the vibration damping plate scheme.

Fig. 3. Variant of the vibration damping plate installation scheme: 1 — rail; 2 — plate; 3 — plate filling; 4 — plate attachment

In a number of frequency ranges (low and high), the plate structure is not suitable for noise reduction. On the other hand, in the case of frequencies characteristic of most of the generated noise, the plate is the most effective minimization method. The plate, which prevents the spread of vibration, also contributes to a qualitative reduction of vibration exposure.

The authors propose to modernize the existing methods of reducing noise and vibration pollution by using more economical materials of plates and mats without a complete reconstruction of the railbed.

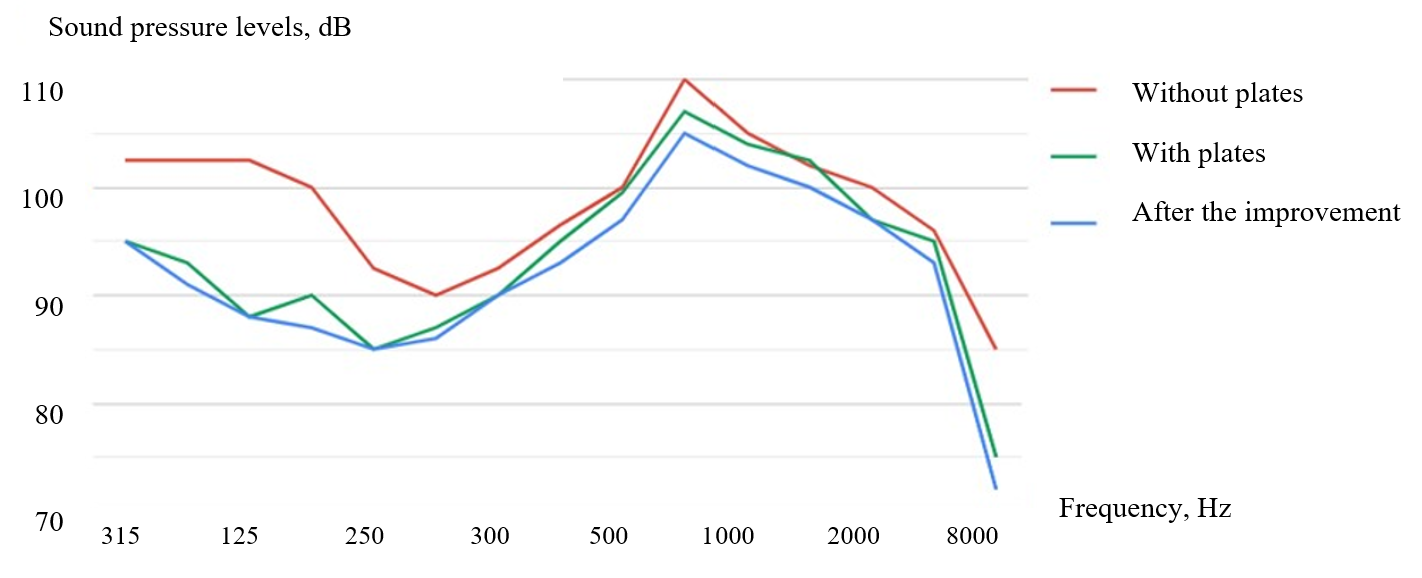

Results. Rail plates usually reduce the noise level by about 3-4 dB, while improving the design — by 5-8 dB. Based on the analysis of the studies, the authors have constructed a graph with the measurement results (Fig. 4)5. Several ways of design improvement are proposed to obtain a better result of noise minimization through the use of modern structures, such as a continuous welded rail, elastic rail fastening, anti-vibration mats and flexible gaskets under the rails. It should be borne in mind that such improvements are available only when replacing or laying a new railway track. The disadvantage of the presented activities is the high cost and complexity of the installation.

Fig. 4. Graph with measurement results

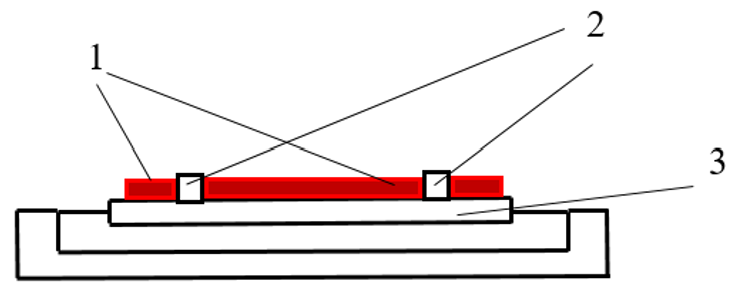

When carrying out measurements, the influence of noise from other vehicles and industrial facilities on the measurement results should be excluded. By analyzing the available options, a budget and relatively simple improvement option was found — the use of a mat system made of recycled synthetic fiber waste that will repeat the shape of the rails. It consists of 3 or 5 parts that are placed between and next to the rails, while the combination significantly reduces the noise from railway traffic (Fig. 5). It is worth noting that when using raw materials for the manufacture of mats from recycled materials, it will be possible to reduce the cost of mats up to 20–30 % or more. It is worth noting that the use of materials in the production of which more than 60 % rubber crumb is used, can also be used as a substitute for filling the lining of the vibration damping plate.

Fig. 5. Variant of the mat system installation scheme: 1 — mat system; 2 — rails; 3 — railbed

When considering the use of the mats system, it is worth identifying all sides of the financial issue. An economic assessment of the effectiveness of environmental protection costs is necessary for the most rational use of limited material and financial resources of an enterprise or organization [9]. It serves to evaluate the advantages (or disadvantages) already obtained, to determine the most appropriate option for the environmental project, as well as to determine the amount of costs necessary to achieve optimal environmental and economic results. When developing a choice for the introduction of new equipment or technology aimed at cleaner production, safety for human health and the environment, as well as the environmental friendliness of the technologies and materials used, should be taken into account.

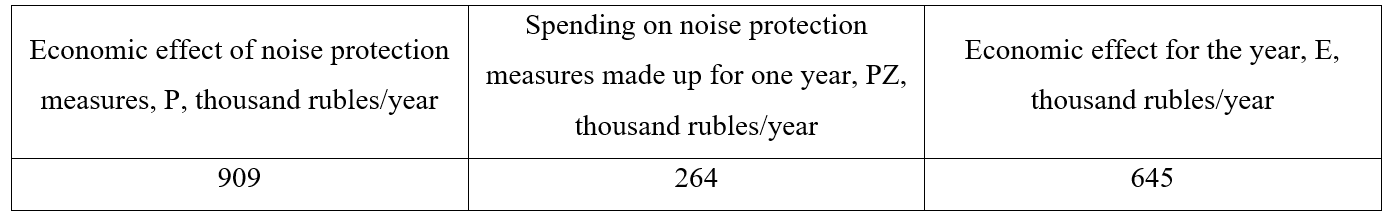

To create a model for calculating economic efficiency in the implementation of a new method for reducing noise and vibration, we use the methodology described in [10], according to which the main calculations will be performed point by point. The economic assessment of measures to minimize and protect against noise is calculated as the calculation of the annual economic effect when using measures. The economic effect for the year is found by calculating the difference between the result obtained when applying protection measures and the annual costs of these measures [11].

Based on the analysis of open sources, we assume that a sheet of vibration damping mat costs from 3.5 thousand rubles for a sheet of one m2 in size. As a result of calculations, a model of economic efficiency from the mat system introduction is presented in Table 2.

Table 2

Economic efficiency model when using an improvement in the method of minimizing noise and vibration effects

Discussion and Conclusion. To minimize harmful vibrocoustic effects, the authors propose a measure to improve one of the methods used — the installation of vibration damping plates. For their production, secondary raw materials can be used in the form of rubber crumbs in an amount of more than 60% of the volume of the material. Such an improvement option has an advantage in places where scheduled repairs of the plates are planned, as well as where the plates have not yet been installed.

By upgrading, it is possible to achieve a noise reduction of 5–8 dB, cheaper material and easier installation of plates. The annual economic effect of the introduction of this method of improving working conditions during the operation of railway transport is about 645 thousand rubles.

1R 2.2.2006-05. Guide on Hygienic Assessment of Factors of Working Environment and Work Load. Criteria and Classification of Working Conditions. Commission on State Sanitary and Epidemiological Rationing; Chief State Sanitary Doctor of the Russian Federation. Bulletin of normative and methodological documents of the State Sanitary and Epidemiological Supervision. 2005. No. 3(21). 114 p. (In Russ.).

2R 2.2.2006-05. Guide on Hygienic Assessment of Factors of Working Environment and Work Load. Criteria and Classification of Working Conditions. (In Russ.).

3SN 2.2.4/2.1.8.562-96. Shum na rabochikh mestakh, v pomeshcheniyakh zhilykh, obshchestvennykh zdanii i na territorii zhiloi zastroiki. Sanitary Standards. State Committee on Sanitary and Epidemiology Surveillance of the Russian Federation. Consortium "Codex". Available from: https://docs.cntd.ru/document/901703278 (accessed 18.01.2023). (In Russ.).

4Terenteva L. S. Geoekologicheskaya otsenka akusticheskogo zagryazneniya primagistral'nykh territorii: na primere g. Voronezha: dis. cand. sci. (geogr.). nauk. Voronezh, 2008. 152 p. (In Russ.).

5GOST 32203 — 2013. Railway rolling stock. Acoustics. Measurement of outward noise. VNIINMASh; Federal Agency for Technical Regulation and Metrology. Moscow, 2014. 20 p. (In Russ.).

References

1. Соколов, Д. А. Характеристика шумового загрязнения и вибрации железнодорожного транспорта. Минимизация воздействия шума и вибрации на работников железнодорожного транспорта / Д. А. Соколов // Студент и наука. — 2022. — № 1 (20). — С. 65–67.

2. Чеботарев, А. Г. Виброакустические факторы рабочей среды при подземной и открытой добыче твёрдых полезных ископаемых / А. Г. Чеботарев, Ю. П. Пальцев // Горная промышленность. — 2012. — № 5 (105). — С. 50–54.

3. Пономарев, В. М. Исследования уровней звука в кабинах локомотивов в условиях эксплуатации / В. М. Пономарев, Д. Н. Васильева // Наука и техника транспорта. — 2016. — № 2. — С. 29–34.

4. Готлиб, Я. Г. Вопросы ограничения шума для оценки условий труда / Я. Г. Готлиб, Н. П. Алимов, В. Н. Азаров // Международный научный журнал "Альтернативная энергетика и экология". — 2013. — № 13 (135). — С. 70–83.

5. Ярусов, Н. И. Шум как вредный производственный фактор / Н. И. Ярусов, В. В. Окулова // Безопасность в профессиональной деятельности. — 2021. — С. 294–298.

6. Анализ и оценка безопасности при эксплуатации дробеструйного аппарата в литейном производстве / В. Я. Манохин [и др.] // Безопасность техногенных и природных систем. — 2022. — № 2. — С. 36–42. doi: 10.23947/2541-9129-2022-2-36-42

7. Сальникова, Л. А. Анализ влияния шума и запыленности на железобетонном производстве / Л. А. Сальникова, Д. А. Соколов, Е. И. Головина // Градостроительство. Инфраструктура. Коммуникации. — 2022. — № 1 (26). — С. 48–50.

8. Канев, Н. Г. Прогноз вибрации рельсового транспорта при проектировании виброизоляции фундаментов зданий. / Н. Г. Канев // Фундаменты. — 2020. — № 2. — С. 51–52.

9. Петрова, Е. Е. Анализ эффективности природоохранных затрат в инвестиционном анализе / Е. Е. Петрова // Вектор науки Тольяттинского государственного университета. — 2010. — № 4 (14). — С. 252–255.

10. Суетина, Т. А. Методика оценки экономической эффективности инвестиций во внедрение мероприятий бережливого производства / Т. А. Суетина, Д. М. Сафина // Российское предпринимательство. — 2018. — Т. 19. — № 10. — С. 3085–3094.

11. Ушакова, Е. О. Методика определения экономической эффективности затрат на природоохранные мероприятия // Гео-Сибирь. — 2006. — Т. 6. — С. 185–190

About the Authors

E. I. GolovinaRussian Federation

Elena I. Golovina

Voronezh

D. A. Sokolov

Russian Federation

Dmitriy A. Sokolov

Voronezh

Review

For citations:

Golovina E.I., Sokolov D.A. Ensuring Occupational Safety at Railway Transport Operation by Upgrading the Systems of Vibration Damping Plates and Rail Plates. Safety of Technogenic and Natural Systems. 2023;(1):39-46. https://doi.org/10.23947/2541-9129-2023-1-39-46