Scroll to:

Digital Safety Monitoring System for Auto Repair Company

https://doi.org/10.23947/2541-9129-2025-9-1-55-64

EDN: HDWZAF

Abstract

Introduction. The scientific literature discusses the potential of artificial intelligence (AI) for ensuring industrial safety. Risk control methods are considered and recommendations for incident prevention are given. The relationship between the competencies of lifting crane operators and the probability of accidents has been studied. Examples of using neural networks for determining the reliability of removable lifting devices are presented. Remote monitoring of operational safety is described. However, the use of AI to manage risks in a car repair station has not been sufficiently studied. This research aims to address this gap. The aim of this work is to demonstrate the potential of neural networks in creating a safety monitoring system for an automobile repair facility.

Materials and Methods. The design materials of the service station at the equipment repair and maintenance center served as basic information. This enterprise was created by specialists of the Department of Operation of Transport Systems and Logistics at the Don State Technical University (DSTU). Risks were classified according to GOST ISO 12 1001 and GOST R 58 7712. Neural networks were trained using open-source libraries for the Python programming language. The digital monitoring system model with visualization was implemented using the AnyLogic simulation system.

Results. The authors of this work trained 20 neural networks and selected five with the lowest error function values (from 74% to 78%). Out of five networks that worked most correctly, one was chosen that predicted the output parameter more accurately — 74%. The neural network with the best performance was a multilayer perceptron with 30 neurons in the input layer, 15 in the hidden layer, and 3 in the output layer. It was used to create a digital twin that warned in real time about potentially dangerous events: the movement of a car, a crane, and the opening of an inspection pit. Additionally, it identified workers without personal protective equipment or access to the work area.

Discussion and Conclusion. The use of a digital safety monitoring system model will make it possible to identify high-risk work areas in advance, and reduce accidents and industrial injuries. The introduction of this model in auto repair facilities involves the installation of sensors and warning systems. In the future, we plan to explore the possibility of integrating algorithms with the risk monitoring system to help personnel repair specific types of machines.

Keywords

For citations:

Egelsky V.V., Nikolaev N.N., Egelskaya E.V., Panfilova E.A. Digital Safety Monitoring System for Auto Repair Company. Safety of Technogenic and Natural Systems. 2025;9(1):55-64. https://doi.org/10.23947/2541-9129-2025-9-1-55-64. EDN: HDWZAF

Introduction. In the near future, machine learning methods will be increasingly used to ensure safety and assess production risks at transport repair facilities. This trend is supported by the rapid development of artificial intelligence and the transport sector. As a result, theoretical and practical research on this subject is becoming increasingly important.

New, more complex machines and equipment are being introduced. Car service companies are increasingly utilizing information and communication technologies. Production algorithms and work processes are changing. These developments can lead to harmful effects on people and equipment, and many of these potentially dangerous situations are difficult to predict. In this case, an integrated approach involves following the rules listed below.

- It is important to monitor staff behavior and to ensure the compliance with safety requirements. It is necessary to focus on issues such as work performance and the use of personal protective equipment (PPE).

- Regular updates on the characteristics and conditions of complex technological equipment are necessary.

- Employees should be aware of the fire extinguishing equipment available at the workplace and know how to use them.

- All employees should familiarize themselves with the evacuation procedures and first aid measures.

Let us note that the quality of such a complex, multifactorial system cannot be determined by the quality of its components. General safety in this case will be a higher-order concept, and artificial intelligence has the best tools to ensure it. Given the obvious inconsistency of the elements discussed above, we should note the importance of self-learning neural networks, which should be used to solve the problems of the presented scientific work.

The production process is exposed to external risks and also generates some of its own. While it is impossible to completely eliminate all potential dangers, there are known methods to reduce and limit them. One such method is the use of protective and monitoring devices, known as collective protective equipment3. The aim of such solutions is to reduce the likelihood of harm or its severity.

In [1], the issues of applying various methods of industrial risk control are discussed in detail, and recommendations are given for the formation and support of a safety system. Paper [2] provides examples of the use of neural networks to ensure the reliability control of lifting accessories. There are studies on the influence of the lifting crane operators’ competencies on the likelihood of emergencies [3].

Patent work is underway in the same direction. For example, patent RU 2 682 020 C1 describes a method for remote safety monitoring during the operation of an object [4]. The solution is based on digital information technology systems. The location of safety control objects is recorded by geo-points, and the data about their parameters is transmitted to the neural network system. Video cameras are used for remote monitoring. The complex combines a server and a mobile software. Patent RU 2 534 371 C1 establishes a method for remote monitoring of hazardous production facilities. To achieve this goal, they will utilize:

- an information technology system;

- means of radio frequency identification;

- a set of devices for implementing the method.

It is proposed to equip safety control facilities with radio frequency identification (RFID). These devices are designed to transmit and receive data through remote devices, which are called readers in the patent. This is how safety parameters of the monitored facilities are fixed and their remote adjustment is ensured. At the same time, an unlimited number of authorized users get Internet access to the database.

Using the example of healthcare, the authors [5] explore the potential of using blockchain and the Internet of Things to create integrated monitoring systems.

In [6], it is proposed to install hazard monitoring sensors at the facility. For this purpose, three situations are modeled:

- it is possible to unlock barriers and open access to the facility;

- it is impossible to unlock barriers and open access to the facility;

- it is necessary to stop the operation of industrial equipment.

In the latter case, the shutdown will occur when the light and sound warning signals are triggered.

Machine learning methods were considered for monitoring the safety of bridges and roads. The author [7] focuses on the detection of damage. In this case, a neural network uses an array of data collected on an object without flaws to train it. This information is compared:

- with new data on intact and damaged objects;

- with forecasts from the vicinity of the output signal of the neural network.

Special attention should be paid to the work of Colombian scientists devoted to the use of neural networks to improve the safety of movement of visually impaired people [8]. The authors created artificial neural networks from a cooperative coevolutionary genetic algorithm. It is responsible for structuring, modifying, and training neural networks. The developed program has formed several neural networks. After the training, they chose those that better prevented collisions, that is, they would be useful to visually impaired people.

An analysis of scientific papers on safety in various fields has revealed common trends:

- verification of existing risks in the system, as well as methods for their reduction, is based on ISO 12100 and ISO 14121;

- machine learning of neural networks is actively used;

- sensors, systems for accumulating and processing information about the state of control objects are widely used;

- sensors and tags should be used to equip both equipment and personnel.

However, we should note that the issues of using artificial intelligence to control and reduce production risks in the field of automotive services are not well-developed. The presented scientific research aims to address this gap. The aim of the work is to demonstrate the potential of using neural networks to form a safety monitoring system at car repair enterprises.

Materials and Methods. The source materials for our scientific research were open data on incidents at the service station. We considered:

- accidents and injuries to personnel;

- the causes for such events.

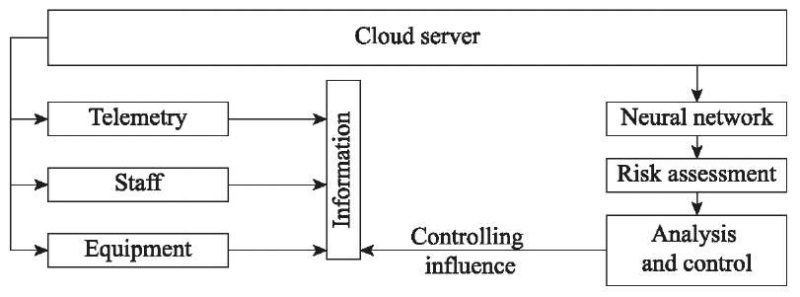

The research involved the development and training of neural networks to assess the level of production risk at car service stations. This research could become the basis for a future unified safety monitoring system based on digital technologies. Figure 1 shows a schematic representation of this system. The neural network was represented as a separate tool for risk assessment.

Fig. 1. The operation scheme of safety monitoring system of a car service company

The cloud server automatically collected information from sensors about telemetry, personnel, personal protective equipment (PPE) usage, and equipment. A neural network then analyzed this information to identify potential risks and provided guidance for control measures.

Thus, a particular task of the presented scientific work was the formation of an artificial neural network. To create it, we needed to select the tools, as well as the input and output parameters.

The authors reviewed ready-made platforms from various companies, including, TensorFlow, PyTorch, Keras, Ex-G Boost, and Statistica.

The first four platforms required writing software code, and when working with “Statistics” this was not necessary. All the necessary functionality was provided in the graphical interface. In addition, Statistica had extensive data processing and presentation tools.

To create a neural network, we used input data on car repairs at a service station. This facility was a division of the Equipment Repair and Maintenance Center, which was created by specialists from the Department of Operation of Transport Systems and Logistics at the Don State Technical University.

Let us consider the creation of a neural network for risk assessment in a body repair area. We should name the safety indicators that were constantly changing [9].

- The remaining lifetime (or service life) of technological equipment. We assign the code A to the indicator.

- The remaining lifetime (or service life) until scheduled maintenance or inspection. We assign the code B to the indicator.

- The time remaining until the planned advanced training of specialists allowed performing the work. We assign the code D to the indicator.

- The time remaining until the next verification of fire extinguishing equipment (mainly fire extinguishers). We assign the code E to the indicator.

Let us list the indicators that were determined by only two conditions: safe and dangerous.

- Completeness of the issue and the correct use of workwear and PPE (issued or not issued, correctly or incorrectly). We assign the code G to the indicator.

- Execution of work by authorized specialists (yes or no). We assign the code H to the indicator.

- Illumination of the work area (meets or does not meet the standards). We assign the code I to the indicator.

- Air temperature in the work area (meets or does not meet the standards). We assign the code J to the indicator.

- Content of controlled harmful substances in the work area (meets or does not meet the standards). We assign the code K to the indicator.

If necessary, the set of indicators can be expanded.

A special class of variables should also be distinguished — linguistic qualitative indicators, that is, verbal descriptions of equipment parameters. For example, the technical condition of the equipment can be “very good”, “good”, “satisfactory”, “poor”, and “very poor”. Such information was obtained by interviewing the personnel who worked with the equipment. We assign the code C to this indicator. Linguistic estimates can be represented numerically using the Harrington desirability function [10].

Thus, the letter designations for safety indicators codes are shown above. They are needed for convenience in entering information into the neural network. Table 1 shows some indicators related to the equipment in the body repair area.

Table 1

Some Safety Indicators of Technological Equipment in the Body Repair Area

|

No. |

Equipment |

Indicator code |

||

|

Remaining lifetime (or service life) |

Technical condition |

|||

|

before scheduled maintenance or inspection |

after scheduled maintenance or inspection |

|||

|

1 |

Electric manual scissors IZ-5403 |

A1 |

B1 |

C1 |

|

2 |

Installation of gas welding and cutting |

A2 |

B2 |

C2 |

|

3 |

Spot welding machine МТ-601 |

A3 |

B3 |

C3 |

|

4 |

Combined electric welding machine |

A4 |

B4 |

C4 |

The creation and training of neural networks requires large data samples, so the quantitative and qualitative input parameters for the body repair area have resulted in a unified view using the Harrington desirability function. This allowed us to determine a generalized risk assessment indicator [10].

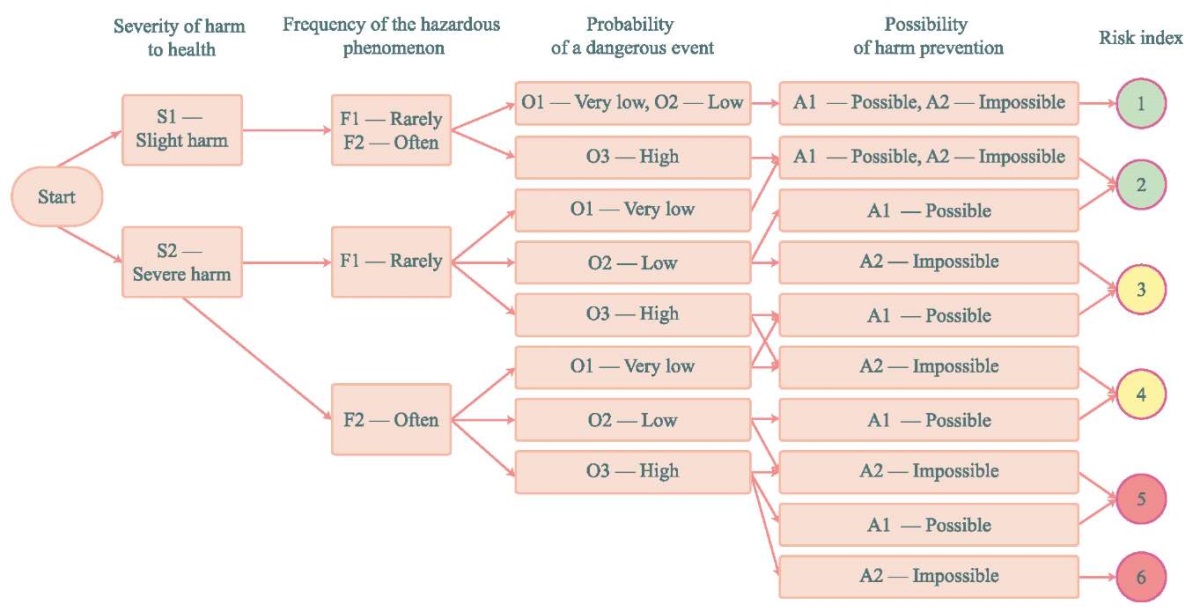

In order to classify the output parameter of a neural network, we used the graph presented in ISO 14121 (Fig. 2).

Fig. 2. Risk assessment graph according to ISO 14121 [10]

Letter designations were taken from the standard. They were not related to the codes in Table 1. It should also be noted that this graph was only a methodological guideline for assessing the level of risk, it did not allow taking into account all the variety of influencing factors. This was exactly what a neural network was trained for.

To assess each dangerous situation, the following conditions were taken into account at the output of the graph:

- risk index equal to 1 or 2 corresponded to the lowest priority of actions (priority 3);

- risk index 3 or 4 corresponded to the average priority of actions (priority 2);

- risk index 5 or 6 corresponded to the highest priority of actions (priority 1).

Thus, it was possible to identify risks that corresponded to the green (lowest), yellow (medium) and red (high) danger levels. In other words, the output parameter of the neural network was a generalized risk assessment indicator defined as green, yellow or red.

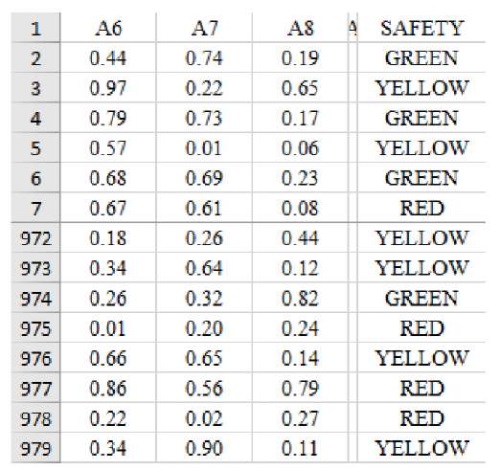

To train neural networks in Excel spreadsheets, we generated input parameters for 1,000 variants of body repair area indicators. With fewer options, neural networks could not qualitatively detect all patterns and relationships. Based on the calculated value of the generalized risk assessment desirability function [11], the risk level was determined for each data variant on a three-color scale. Figure 3 provides a fragment of the neural network training data. This was a part of the codes not included in Table 1.

Fig. 3. A fragment of data for neural network training

The source information was imported into a data table created in the Statistica workbook.

The “Neural networks” module of the Statistica environment solved problems of five types:

- regression;

- classification;

- time series (regression);

- time series (classification);

- cluster analysis.

In the developed neural network model, the output parameter was the risk level (green, yellow, red), so this problem was solved as a classification problem.

Next, one needed to select the type of artificial neural network. Within the framework of this work, we considered:

- multilayered perceptron, MLP;

- radial basis function.

The system offered, and the authors used:

- the number of neurons of the hidden layer;

- the number of trained and returned networks;

- activation functions of the hidden and output layers of the network.

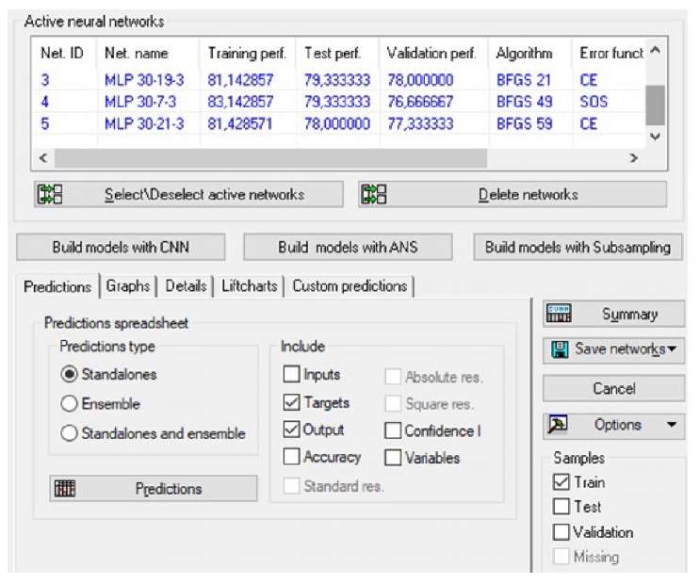

Results. The system split the input data into training, test, and validation samples. Their ratio was left at the default. The sum of squared deviations and cross-entropy were chosen as error functions, which Statistica used to evaluate the quality of neural network training.

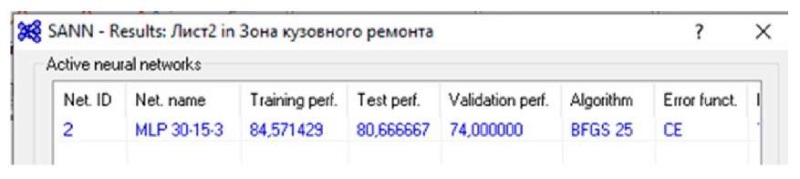

As a result, 20 neural networks were trained and five neural networks with the lowest error functions were selected (Fig. 4). The system automatically chose the type of error function for each neural network. In the used version of Statistica, the window with trained neural networks did not move vertically, so only three of the five networks were shown in Figure 4. Here, the error function values ranged from 76.7% to 78%. Neural networks 1 and 2, hidden in Figure 4, had error function values of 77.2% and 74%, respectively.

Fig. 4. The learning process of MLP architecture neural networks

The error of the neural network was estimated using cross-entropy [12]. The system chose a hyperbolic tangential function as the activation function of the hidden layer of neurons, and a multidimensional logistic function for the output layer of neurons.

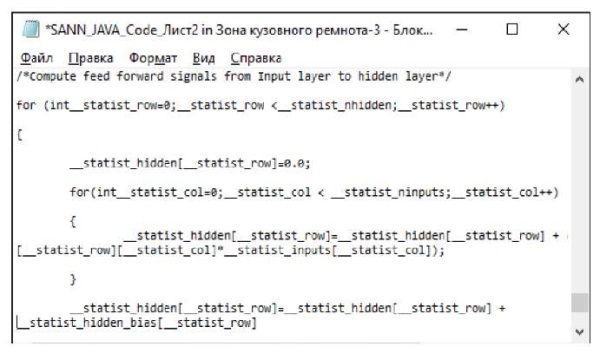

After saving the resulting neural network in xml format, it could be downloaded and used for calculations in the Statistica environment. Here, one could also save a neural network as code in several programming languages for later use in software development.

Of the five trained neural networks that best corresponded to the validation and test data samples, we determined the one with the highest accuracy in predicting the output parameter — 74%. This indicator was expressed as a percentage of convergence with the output parameters of the samples (Fig. 5).

Fig. 5. The result of neural network training

The best neural network that determined the risk level for the body repair area had the MLP 30-15-3 structure, that is, a multilayer perceptron with 30 neurons in the input layer, 15 neurons in the hidden layer and 3 neurons in the output layer. The input layer of 30 neurons was determined by the number of incoming indicators for a given work area. There are 10 groups of indicators described in the “Materials and Methods” section, but due to the limited length of this article, it is not possible to list them all. If needed, the number of indicators could be increased.

The resulting neural network was translated into the Java programming language. The code (Fig. 6) was implemented into the digital twin program [13] and the artificial intelligence system [14] of the car service company safety assessment platform developed on AnyLogic.

Fig. 6. A fragment of the neural network code in Java

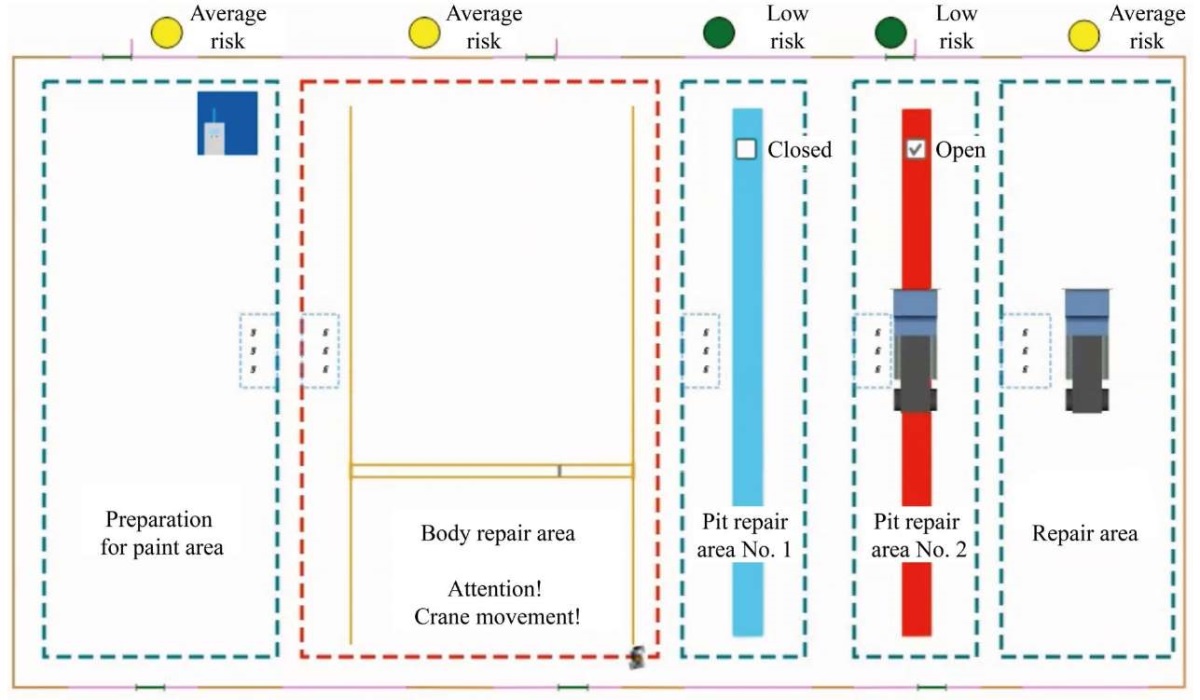

Figure 7 provides the digital twin of the car service company safety assessment platform, developed at AnyLogic.

Fig. 7. Digital twin of the safety assessment platform

The digital twin in real time [15] displayed the risk levels at each site in the production workshop and alerted users to potentially dangerous events:

- movement of the crane;

- entry and exit of the car;

- opening of the inspection pit.

Employees without personal protective equipment and persons who did not have access to the hazardous work area were identified.

As a result, the dangerous factors of the car service company's production process were detected in a timely manner. Their comprehensive assessment was presented as a certain level of risk. At the same time, two factors could hinder the development of an unfavorable scenario:

- staff received timely information about the danger in graphic (color) and sound form;

- risk factors were eliminated, i.e. measures were taken to prevent accidents and industrial injuries.

Discussion and Conclusion. The results of the presented study close one of the gaps in risk management. Its scientific novelty is due to the specific nature of car service companies' activities, which have not been previously considered from this perspective. The first and most likely area of practical application of the proposed model of a digital safety monitoring system is car repair shops. However, it should be noted that its practical implementation involves mandatory installation of sensors and warning systems at the facility. The use of a digital safety monitoring system model will allow for the detection of high-risk work areas in advance and reduce occupational injuries. Thus, the digital twin of the car service company's safety assessment platform generated and transmitted the following information necessary for monitoring and management decisions:

- in the area of preparation for painting, — average risk level;

- in the body repair area — average risk level, a moving crane requires special attention;

- in the 1st pit repair zone — low risk level when the pit is open;

- in the 2nd pit repair zone — low risk level when the pit is closed;

- in the repair area — average risk level.

Further research plans include the development of a risk monitoring system at a car service station. This system can be supplemented with features that will assist staff in maintaining specific models of vehicles. Combining the assistance and monitoring systems can help avoid errors and increase safety in the workplace. This is especially important when servicing vehicles with unique design features, such as military vehicles. We plan to use augmented reality technology to display visual cues on specialized screens.

1. GOST ISO 12100–2013. Safety of Machinery. General Principles for Design. Risk Assessment and Risk Reduction. (In Russ.) URL: https://ohranatruda.ru/upload/iblock/4c0/4293772097.pdf?ysclid=m4jji252s3577051840 (accessed: 10.11.2024).

2. GOST R 58771–2019. Risk Management. Risk Assessment Technologies. (In Russ.) URL: https://meganorm.ru/Data2/1/4293724/4293724640.pdf?ysclid=m4jjuuqqtv740249077 (accessed: 10.11.2024).

3. The Labor Code of the Russian Federation. As amended on December 26, 2024. Part 1. Chapter 1. Article 4. (In Russ.) URL: https://www.consultant.ru/document/cons_doc_LAW_34683/ (accessed: 29.12.2024).

References

1. Panfilov AV, Bakhteev OA, Deryushev VV, Korotkiy AA. Adaptive Remote Monitoring and Control System for the Operation of Hazardous Facilities Based on a Risk-Based Approach. Safety of Technogenic and Natural Systems. 2020;(2):19−29. https://doi.org/10.23947/2541-9129-2020-2-19-29

2. Egelsky VV, Nikolaev NN, Egelskaya EV, Korotkiy AA. Use of Artificial Intelligence to Monitor the Reliability of Removable Load-Handling Devices. Safety of Technogenic and Natural Systems. 2024;2:57−67. https://doi.org/10.23947/2541-9129-2024-8-2-57-67

3. Egelsky VV, Nikolaev NN, Egelskaya EV, Korotkiy AA. Influence of the Competencies of Lifting Crane Specialists on the Probability of Emergencies. Safety of Technogenic and Natural Systems. 2023;2:70–79. (In Russ.) https://doi.org/10.23947/2541-9129-2023-7-2-70-79

4. Lagerev AV, Lagerev IA, Kanygin PS, Kinzhibalov AV, Kinzhibalov AA, Kobilev AG, et al. A Method of Remote Safety Control during the Operation of an Object Based on Digital Information Technology Systems. Patent RF No. 2682020. 2019. 14 p. (In Russ.)

5. Sanjay Kumar Jena, Ram Chandra Barik, Rojalina Priyadarshini. A Systematic State-of-Art Review on Digital Identity Challenges with Solutions Using Conjugation of IOT and Blockchain in Healthcare. Internet of Things. 2024;25:101111. https://doi.org/10.1016/j.iot.2024.101111

6. Müller E, Hopf H. Competence Center for the Digital Transformation in Small and Medium-Sized Enterprises. Procedia Manufacturing. 2017;11:1495–1500. https://doi.org/10.1016/j.promfg.2017.07.281

7. Le HB, Felici F, Paley JI, Duval BP, Moret J-M, Coda S, et al. Distributed Digital Real-Time Control System for TCV Tokamak. Fusion Engineering and Design. 2014;89(3):155–164. https://doi.org/10.1016/j.fusengdes.2013.11.001

8. Alvarado Coral JD, España E Muñoz. Sistema Anticolisión para Invidentes Usando Redes Neuronales Evolutivas. Inge Cuc. 2018;14(2):28–44. http://doi.org/10.17981/ingecuc.14.2.2018.03

9. Fedorchenko SG, Fedorchenko GS. Integral Measure of Evaluation of the Status of Energy Security. Problems of the Regional Energetics. 2014;24:1–16. (In Russ.) URL: https://journal.ie.asm.md/assets/files/03_01_24_2014.pdf (дата обращения: 29.12.2024).

10. Zhang Qi, Durfee EH, Satinder Singh. Risk-Aware Analysis for Interpretations of Probabilistic Achievement and Maintenance Commitments. Artificial Intelligence. 2023;317:103864. https://doi.org/10.1016/j.artint.2023.103864

11. Menzefricke JS, Wiederkehr I, Koldewey Ch, Dumitrescu R. Socio-Technical Risk Management in the Age of Digital Transformation — Identification and Analysis of Existing Approaches. Procedia CIRP. 2021;100:708–713. https://doi.org/10.1016/j.procir.2021.05.094

12. Popov K, Bold RDe, Chai H-K, Forde MC, Ho CL, Hyslip JP, et al. Big-Data Driven Assessment of Railway Track and Maintenance Efficiency Using Artificial Neural Networks. Construction and Building Materials. 2022;349:128786. https://doi.org/10.1016/j.conbuildmat.2022.128786

13. Liu Liu, Ningshuang Zeng, Yan Liu, Daguang Han, König M. Multi-Domain Data Integration and Management for Enhancing Service-Oriented Digital Twin for Infrastructure Operation and Maintenance. Developments in the Built Environment. 2024;18:100475. https://doi.org/10.1016/j.dibe.2024.100475

14. Kutscher V, Anokhin O, Anderl R. Enhancing Digital Twin Performance Through Simulation of Computerized Numerical Control Firmware. Procedia Manufacturing. 2020;49:69–74. https://doi.org/10.1016/j.promfg.2020.06.013

15. Vogt A, Müller RK, Kampa T, Stark R, Großmann D. Concept and Architecture for Information Exchange between Digital Twins of the Product (CPS) and the Production System (CPPS). Procedia CIRP. 2021;104:1292–1297. https://doi.org/10.1016/j.procir.2021.11.217

About the Authors

V. V. EgelskyРоссия

Vladislav V. Egelsky, Postgraduate Student of the Department of Operation of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

N. N. Nikolaev

Россия

Nikolai N. Nikolaev, Cand. Sci. (Eng.), Associate Professor of the Department of Operation of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

E. V. Egelskaya

Россия

Elena V. Egelskaya, Cand. Sci. (Eng.), Associate Professor of the Department of Operation of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

E. A. Panfilova

Россия

Elvira A. Panfilova, Cand. Sci. (Philosoph.), Associate Professor of the Department of Transport Systems Operation and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

Review

For citations:

Egelsky V.V., Nikolaev N.N., Egelskaya E.V., Panfilova E.A. Digital Safety Monitoring System for Auto Repair Company. Safety of Technogenic and Natural Systems. 2025;9(1):55-64. https://doi.org/10.23947/2541-9129-2025-9-1-55-64. EDN: HDWZAF

JATS XML