Scroll to:

Methodology for Determining the Classification Group of Jib Cranes of Foreign Companies when Assessing Their Technical Condition during Current Sanctions

https://doi.org/10.23947/2541-9129-2025-9-2-158-169

EDN: LOEFTJ

Abstract

Introduction. Currently, more than 7,000 legal entities and individual entrepreneurs in the Russian Federation operate hazardous production facilities (HPFs) and over 90,000 lifting facilities, including cranes, hoists, and elevators. Periodically, serious accidents leading to injuries and deaths are recorded at these facilities, emphasizing the importance of ensuring safety on lifting cranes. However, sanctions against imported cranes installed in ports make it difficult to ensure their safe operation, as many of these cranes exceed or approach the end of their service life. According to the regulatory legal acts of the Russian Federation, an industrial safety inspection is required for further operation of these cranes. The existing studies on the assessment of technical condition of lifting machines primarily focus on issues related to residual life. However, the analysis reveals that the features of evaluating the condition of cranes manufactured by foreign companies, in particular, their actual loads as determined by FEM, have not been thoroughly investigated. This discrepancy between actual and specified loading leads to increased risk of accidents. The aim of this research is to develop a methodology for determining the actual classification group of jib cranes produced by foreign companies, which will allow for an objective assessment of their technical condition during the industrial safety inspections, as well as verifying the developed methodology through a specific example.

Materials and Methods. The assessment was based on statistical data collected over the past 27 years. The study was conducted through a systematization of typical damages to cranes identified during industrial safety inspections. Statistical data on the number of cranes and accidents were collected from open sources. During the observation period, there were 254,250 cranes, and the average number of accidents was 42.29, which allowed us to calculate a background probability of accidents of 1.66 ∙ 10⁻⁴. This allowed us to identify an excess in the permissible destruction probability, which was 2x10⁻³, compared to the established regulatory level of 10⁻⁴. Based on this, we analyzed the technical condition of cranes and refined the risk assessment methodology. The direct analysis of the technical condition of cranes was based on the study of loading functions, which depended on the weight of the load and the boom outreach, considered as random variables. For this purpose, we collected and processed primary information in the form of histograms of the distribution of transported cargo masses and boom outreach of the tested cranes. We used these data to calculate the remaining fatigue life of the resource-determining component of the metal structure and the probability of structural failure. Statistical data processing techniques were used to formalize conclusions about the risk level of crane operation based on specific numerical values of accident and damage probabilities, taking into account economic and social factors.

Results. To assess the technical condition of jib cranes manufactured by foreign companies, a methodology was developed to determine the actual classification group. The methodology included calculating the load distribution coefficient (Кр) through load moments, estimating the residual resource by a characteristic number, calculating fatigue stresses for a resource-determining unit, determining the probability of structural failure, and assessing the risk of an accident. The article provides an example of the application of this technique to a specific jib crane. For a crane with design Кр = 0.30 (group A6) and a standard characteristic number of 125,000, the actual characteristic number was 179,323, indicating that service life had been exhausted. Verification calculation of fatigue stresses in the reference contour showed close proximity to the ultimate strength. The value of the probability of destruction, considering the statistical data on the crane load, exceeded the permissible value.

Discussion and Conclusion. The analysis of the results, using a specific example, showed that exceeding the passport classification of the crane's operating mode, and as a result, exceeding the assigned resources of its structural components, led to a significant increase in the risk of accidents. Based on the examination, it was found that the actual classification group of the crane's operating mode exceeded the passport value and amounts to A6 instead of A5. The developed methodology for assessing the actual classification group of the operating mode of jib cranes from foreign manufacturers allows for a significant reduction in the likelihood of structural failure and accident rate during industrial safety inspections. At the same time, it is recommended to use the background probability of a lifting crane accident of 1.66·10⁻⁴ and the average value of material damage of 73.2 million rubles in calculations.

Keywords

For citations:

Simonov D.N., Khvan R.V., Panfilova E.A., Ternovskoi L.A. Methodology for Determining the Classification Group of Jib Cranes of Foreign Companies when Assessing Their Technical Condition during Current Sanctions. Safety of Technogenic and Natural Systems. 2025;(2):158-169. https://doi.org/10.23947/2541-9129-2025-9-2-158-169. EDN: LOEFTJ

Introduction. Currently, there are 51,670 hazardous production facilities registered in the Russian Federation that operate more than 284,000 lifting devices, including 224,363 cranes. It's worth noting that 51.2% of these lifting devices have already reached the end of their standard service life.

In 2023, there were 30 recorded accidents at lifting facilities. The analysis of causes of accidents over the past few years has revealed that the main contributing factors are: poor production control [1], operation of faulty lifting structures, and inadequate organization of inspections, maintenance, and scheduled repairs for lifting structures [2].

The sanctions imposed by producing countries have affected foreign lifting cranes that are mainly used in sea and river ports. For many imported lifting cranes, their service life has reached a critical point or exceeded the established standard [3]. To ensure the safe operation of these devices in accordance with the regulatory legal acts of the Russian Federation, an industrial safety inspection is required. This mandatory step ensures the reliability and safety of crane operation and compliance with applicable standards and regulations. The classification groups, classes of use, and loading modes for these cranes are based on the international European standard FEM 1.001-19981 “Rules for the Design of Hoisting Appliances”, which is equivalent to the Russian standard GOST 34-017-20162. A comparative analysis of these regulatory documents has shown that, according to FEM3, the crane loading is indicated as Q2 in the certificate, while the actual load corresponds to Q3. This results in an excess of the classification group value and increased risk of accidents.

The main challenge of operating such cranes in the context of sanctions imposed by manufacturing countries is the termination or severe restriction of the supply of equipment, spare parts, and assemblies for these cranes, as well as disruption of contact for consulting services related to their operation. Additionally, there has been a cessation of equipment maintenance by specialists from supplier companies, as well as remote monitoring of equipment status and updates to software products that ensure the safe operation of the cranes.

Jib cranes, in accordance with the legislation of the Russian Federation No. 116 FZ4, belong to potentially dangerous objects of hazard class IV, and must comply with standard safety requirements, such as reliability, durability, maintainability, and safety [4][5].

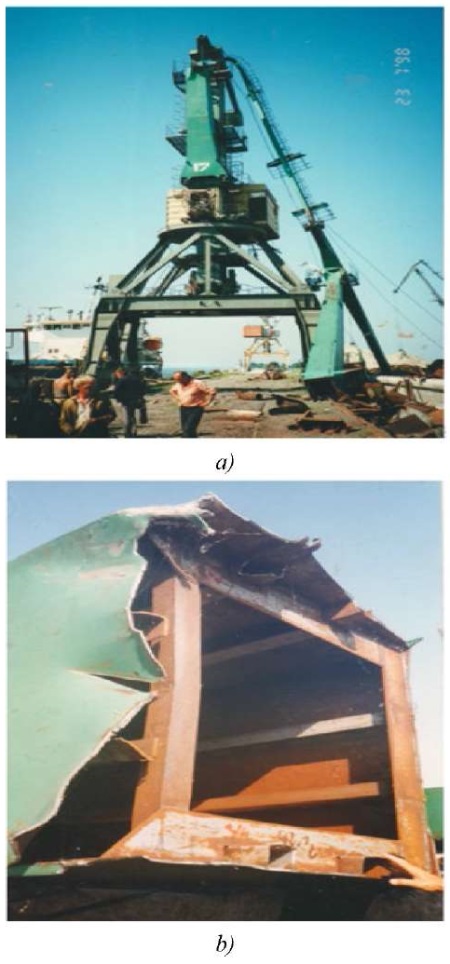

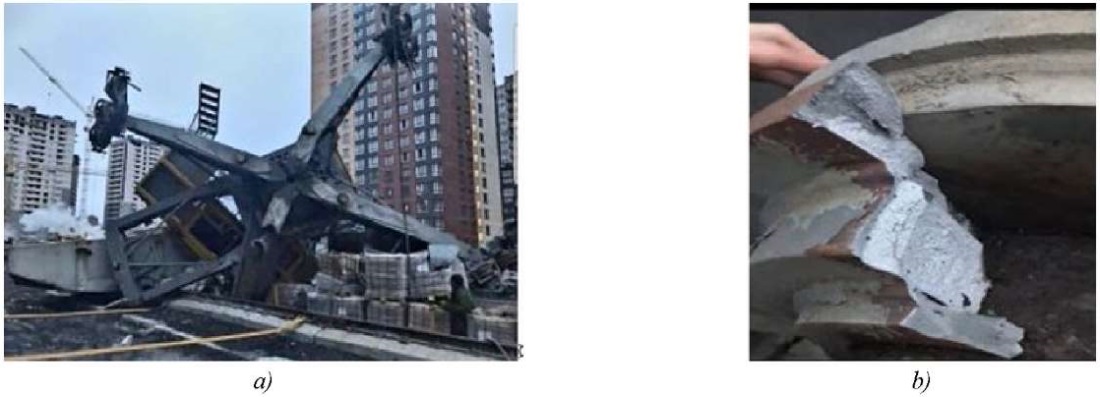

During the scheduled expert inspections of cranes, the presence of separate resource-determining (resource-limiting) components and elements of metal structures was established [6]. Damage (resource depletion) of such components can lead to the complete destruction of the structure. For example, there have been accidents related to: the destruction of the rail attachment unit of the boom outreach mechanism for an Albatross type portal jib crane (Fig. 1), the destruction of the outrigger attachment unit for a tower crane (Fig. 2), the destruction of the lifting mechanism for a portal jib crane (Fig. 3).

Fig. 1. Accident of an Albatross type portal jib crane due to the destruction of the rail attachment unit of the boom departure:

a — general view; b — place of destruction

Fig. 2. Accident of a tower crane due to the destruction of the attachment point of the outriggers of the carriage frame:

a — general view; b — place of destruction

Fig. 3. An accident of a portal jib crane due to the destruction of the lifting mechanism:

a — before the accident; b — after the accident

The described accidents have a common cause, which is exceeding the crane's classification group (mode) of the specified value in the passport, which in turn leads to exceeding the service life for the crane as a whole and the resource-determining components of the crane specifically.

The task of conducting an objective assessment of the technical condition of jib cranes during the process of industrial safety inspection is essential. Therefore, the aim of this work was to develop a methodology for determining the actual classification group (mode) of jib cranes of foreign companies and to test the developed methodology using a specific example.

Materials and Methods. Gottwald type cranes have an A5 or A6 crane operating mode classification group with recommended parameters according to International European standards FEM 1.001–19985 [8]:

- crane classification group A;

- mechanism classification group M;

- other components classification group Е;

- usage class U for each group;

- loading mode Q for each group.

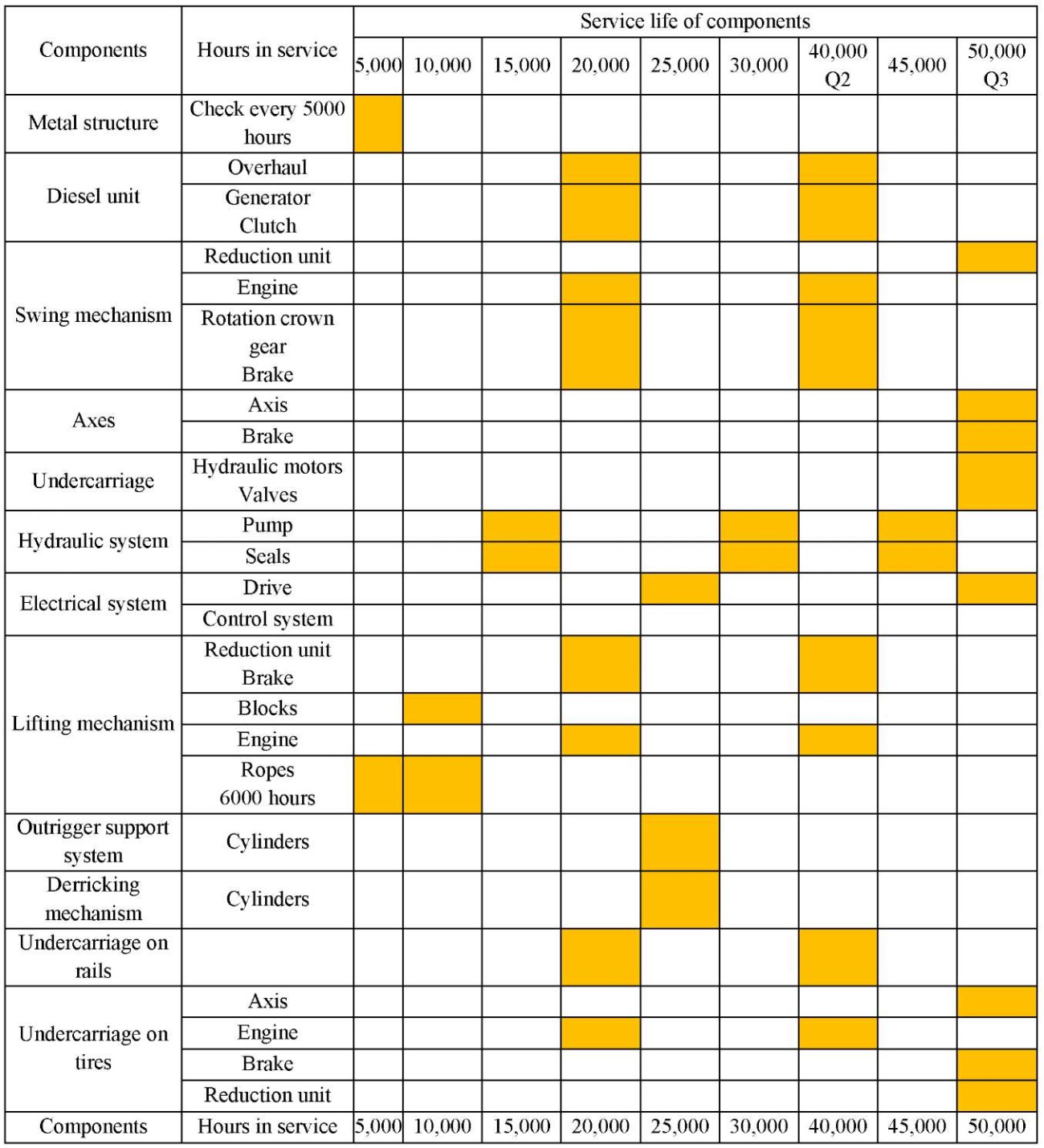

With these parameters, the expected lifetime of the components and mechanisms [9] of the crane must be achieved, expressed in operating hours (Table 1).

Table 1

Service life diagram for HMK, HSK type cranes

This table determines the recommended service life in operating hours for the bearing metal structures of cranes, as well as for the main components of the crane — lifting, rotating, chassis, electrical, and hydraulic equipment — under a specific loading mode Q. For instance, the service life of a crane's metal structure under loading mode Q2 was 40,000 operating hours.

According to FEM6, Q2 load mode is recommended for imported cranes. However, when we analyzed the actual load on several cranes that were surveyed, we found that the current load mode corresponded to Q3 level, which exceeded the passport values for the crane's classification group [10].

When conducting an industrial safety inspection, it is essential to collect data on the actual loading of the crane [11]. However, it is not always possible to use parameter recorders, as they may not be operational. Therefore, in such situations, it was decided to use statistical data on the actual loading of cranes.

Loading of jib cranes is a function of at least two parameters — the load weight and the boom outreach, the product of which determines the load moment. In general, these parameters can be random values [12]; they should be taken into account when determining the crane load.

Therefore, the key task of determining the classification group (mode) of the crane is to gather initial data and construct histograms of the distribution of transported cargo masses and boom outreach of the crane under test. The distribution of random variables (the mass of the transported goods and the boom outreach of the crane) is characterized by such quantities as the average value (mathematical expectation) and the standard deviation (variance).

Let us take the random values distribution law (the mass of the transported goods and the boom outreach of the crane) as normal, which will greatly simplify calculations in the future [13]. The accepted assumptions are supported by studies of the boom outreach and angle of inclination of portal jib crane presented in [7][8].

Results. In order to obtain more objective information to make an informed decision on further operation of jib cranes of foreign companies, a methodology has been developed for assessing the actual classification group (mode) for conducting an industrial safety inspection. The process included several stages. The first step was to determine the actual value of the load distribution coefficient Кр through the load moments and compare it with the passport value. The second stage included an assessment of the remaining operating life and its comparison with the standard value. Then, the maximum fatigue stresses of the resource-determining unit of the metal structure were calculated, followed by a comparison of the obtained value with the limit value. The probability of structural failure was also calculated and compared with the acceptable value. An important element of the assessment was the analysis of the accident risk level.

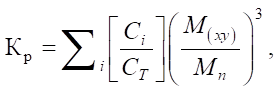

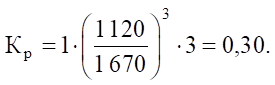

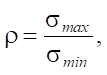

As an example, we considered a specific case where the actual classification group (mode) of a jib crane was determined and it was recommended for decommissioning. At the first stage, the load distribution coefficient Кр was determined in terms of load moments from the expression:

(1)

(1)

where Ci/CT — ratio of the number of operating cycles of a crane with an average load torque to the total number of cycles (we assumed 1 in calculations); М(xy) — mathematical expectation of the load moment; Мn — maximum load moment of the crane specified in its certificate; Мxy = 28×40 = 1,120 t∙m; Мn = 33.4×50=1,670 t∙m (40 and 50 — average and highest outreach value in the hook mode; 28.0 and 33.4 — average and highest lifting capacity of the crane in the hook mode according to cargo characteristics).

(2)

(2)

According to [5][6][9], the crane classification group (mode) is generally determined depending on the class of use (U0 – U9), characterized by the maximum number of cycles per service life, and the loading mode (Q1–Q4). Calculated value of the load distribution coefficient Кр = 0.30 corresponded to A6 classification group (mode) of the crane as a whole, but was higher than A5 nominal value [14].

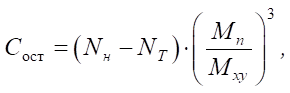

At the second stage, the residual life of the crane was estimated based on the current value of the characteristic number, which was a measure of the crane's life, and was determined taking into account the load distribution coefficient of the crane for the corresponding loading mode and the number of operating cycles [15].

The limiting condition of the crane in terms of operating time occurred if the current characteristic number was equal or higher than the standard value. The residual life was calculated using the following equation:

(3)

(3)

where Nн — standard value of the characteristic number, which was determined by the crane's classification group and operating mode according to [9][10]; Nт — current value of the characteristic number.

(4)

(4)

For the example discussed earlier, the additional conditions were as follows:

Nн = 125,000 — standard value of the characteristic number for A5 crane classification group (mode);

С = 596,228 — estimated number of working cycles;

Then the current value of the characteristic number was:

Nт = 596,228×0.67³ =179,323;

179,323 > 125,000;

Nт > Nн .

Conclusion: the resource was exhausted.

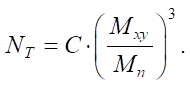

At the next stage, a verification calculation of the resource-determining assembly of the metal structure [11] for fatigue resistance was performed according to the formula.

(5)

(5)

where smax — maximum stress; av — coefficient of the operating mode of the element; RV — calculated fatigue resistance calculated considering time resistance, steel, and the group of elements' joints, taking into account the degree of stress concentration; gv — coefficient that took into account the type of stress state and the asymmetry of operating stresses;

gс — coefficient of operating conditions.

The value of operating mode coefficient av was determined based on the crane's operating mode group and the level of stress concentration. The value gv was calculated based on the type of stress state and the stress asymmetry coefficient:

(6)

(6)

where smin and smax — maximum and minimum absolute stresses in the calculated element.

As an example, we calculated the reference contour of the rotary device on a portal jib crane. The results of this calculation can be found in Table 5, which shows the fatigue resistance.

Table 5

Fatigue resistance calculation results

|

Parameter |

Value |

|

Maximum compressive stress, smax |

65 MPa |

|

Maximum tensile stress, smin |

55 MPa |

|

Coefficient of the operating mode of the element av |

1.5 |

|

Calculated Rv fatigue resistance for the 6th group of elements in terms of stress concentration |

60 MPa |

|

Coefficient of the operating mode of the element, av |

1.5 |

|

Coefficient that takes into account the type of stress state and the asymmetry of the acting stresses, gv |

1.08 |

|

Coefficient of operation conditions, gс |

0.7 |

|

Fatigue resistance strength condition |

65 MPa not more than 68 MPa |

The verification calculation of the reference contour of the portal jib crane's rotary device for fatigue resistance indicated that the maximum stress values calculated were close to the limiting value.

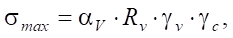

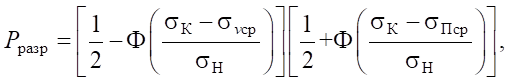

Based on the statistical data on the load of the jib crane, we could determine the probability of destruction of the resource-determining element of the metal structure using the following expression:

(7)

(7)

where Ф(х) — Laplace function; σн — average square deviation of stresses in the distribution of the load factor;

σп — average square deviation of stresses in the distribution of the strength factor; σvср — average calculated stress in the structure; σпср — average value of the fatigue limit of the structural material, taking into account the cycle asymmetry; σк — calculated stress value at the intersection point of the alternating stresses distribution of and the distribution of fatigue limits, which could be obtained from solving the equality of load and strength distribution equations. Table 6 provides the calculation results.

Table 6

The results of calculating the probability of destruction of the resource-determining element of a metal structure

|

Parameter |

Value |

|

σvср |

58 MPa |

|

σн |

2.5 MPa |

|

Х(н) |

1.6 |

|

Ф(н) |

0.4452 |

|

σпср |

68 MPa |

|

σп |

3.3 MPa |

|

σк |

62 MPa |

|

Х(п) |

1.81 |

|

Ф(п) |

0.4649 |

|

Estimated value of the probability of destruction Р = (0.5 – 0.4452) ×(0.5 – 0.4649) = 0.0548×0.0351 |

2×10-3 |

|

Acceptable probability value |

1.0 – 0.9999=0.0001 (10–4) |

The safety condition was not fulfilled, because the calculated value of the probability of destruction equal to 2×10–3 exceeded the permissible value of 10–4.

For comparison, Table 7 shows the failure probabilities of jib-type crane elements.

Table 7

Probability of failure of jib-type crane elements

|

Name |

Event |

Probability |

|

Brake |

Failure |

3.5×10–5 – 3.3×10–7 |

|

Rope |

Wire breakage Wear and tear |

3.6×10–4 3.8×10–5 |

|

Blocks |

Failure |

2.7×10–3 – 5.6×10–4 |

|

Engine |

Failure |

1.28×10–4 – 6.2×10–7 |

|

Metal structure |

Damage |

2.5×10–5 |

|

Starting-and-control devices |

Failure |

9.5×10–4 |

|

Running wheels |

Wear and tear |

9.9×10–6 |

|

Electrical wiring |

Failure |

1.9×10–4 |

|

Reducer |

Failure |

8.7×10–6 |

At the final stage, based on regulatory and technical documentation, a risk assessment was conducted to determine the level of safety for further operation of the jib crane. The background risk of accidents for lifting cranes was calculated using statistical data from the last 27 years:

- average number of cranes during the observation period— 254,250 units;

- average number of accidents — 42.29;

- background probability of an accident — 42.29/254,250 = 0.000166 = 1.66·10–4

Table 8 presents the damage from accidents at hazardous production facilities with lifting cranes, including direct losses, costs for localizing and mitigating the consequences, and economic losses based on statistical data from open press sources.

Table 8

Economic damage from accidents

|

Year |

Economic damage, rub. |

Year |

Economic damage, rub. |

|

2003 |

16,000,000 |

2014 |

50,000,000 |

|

2004 |

8,000,000 |

2015 |

78,000,000 |

|

2005 |

60,000,000 |

2021 |

150,000,000 |

|

2008 |

165,000,000 |

2022 |

73,778,191 |

|

2009 |

62,000,000 |

2023 |

70,648,042 |

For comparison, Table 9 provides information on the probability of events with other types of equipment operated at hazardous production facilities.

Table 9

Probabilities of events for various types of equipment

|

Type of equipment |

Event |

Probability |

|

Pressure vessels |

Depressurization |

4.0×10–5 – 6.2×10–6 |

|

Total destruction |

3.0×10–7 |

|

|

Tanks for flammable liquids |

Total destruction |

5.0×10–6 |

|

Fixed-roof tanks |

Fire |

9.0×10–5 |

|

Industrial pipeline |

Break |

1.4×10–6 – 6.4×10–9 |

|

Metallurgical workshop |

Fire |

1.9×10–5 |

|

Road transport (USA) |

Accident |

3×10–4 |

|

Road transport (Russian Federation) |

Accident |

2.7×10–4 |

|

Water, air transport (USA) |

Accident |

9×10–6 |

|

Water transport (Russia) |

Accident |

2.2×10–7 |

|

Air transport (Russian Federation) |

Accident |

3.4×10–7 |

|

Railway transport (USA) |

Accident |

4×10–6 |

|

Railway transport (Russian Federation) |

Accident |

2×10–8 |

Discussion and Conclusion. Using a specific example, the results showed that exceeding the crane's classification group (mode) and the assigned crane resources as a whole, including structural elements that determine the resource, will inevitably increase the risk of accidents involving jib cranes. Therefore, it was determined that the actual classification group of the crane was A6, which exceeds the passport value A5.

The developed methodology for assessing the actual classification group (mode) of jib cranes of foreign companies will significantly reduce the likelihood of structural failure of jib cranes and the level of accidents during industrial safety inspections. Currently, in Russia, the acceptable level of risk is determined qualitatively without specific numerical values for the probability of accidents or the amount of damage. The numerical values of the probability of accidents and the amount of damage are determined based on the economic and social development of society and may vary depending on the industry. Therefore, it is recommended to use the background probability of a lifting crane accident of 1.66·10-4 and an average material damage value of 73.2 million rubles in calculations.

1. F.E.M. 1.001–1998. Rules for the Design of Hoisting Appliances. VBOOK.PUB. URL: https://vbook.pub/documents/fem-1001-3-edition-revised-1998101-rules-for-the-design-of-hoisting-appliances-5wglvlzj78o7 (accessed: 24.02.2025).

2. GOST 34 017–2016. Cranes. Classification of operating modes. Electronic Fund of Legal and Regulatory and Technical Documents. URL: https://docs.cntd.ru/document/1200144610?ysclid=mb95dc232z408543082 (In Russ.) (accessed: 24.02.2025).

3. Id.

4. On Industrial Safety of Hazardous Production Facilities. Federal Law No. 116 FZ dated 21 July, 1997. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/9046058?ysclid=mb95ftxllk548884359 (accessed: 24.02.2025).

5. F.E.M. 1.001–1998. Rules for the Design of Hoisting Appliances. VBOOK.PUB. URL: https://vbook.pub/documents/fem-1001-3-edition-revised-1998101-rules-for-the-design-of-hoisting-appliances-5wglvlzj78o7 (accessed: 24.02.2025).

6. F.E.M. 1.001–1998. Rules for the Design of Hoisting Appliances. VBOOK.PUB. URL: https://vbook.pub/documents/fem-1001-3-edition-revised-1998101-rules-for-the-design-of-hoisting-appliances-5wglvlzj78o7 (accessed: 24.02.2025).

References

1. Tong Yang, Ning Sun, He Chen, Yongchun Fang. Motion Trajectory-Based Transportation Control for 3-D Boom Cranes: Analysis, Design, and Experiments. IEEE Transactions on Industrial Electronics. 2019;66(5):3636–3646. https://doi.org/10.1109/TIE.2018.2853604

2. Xing Pan, Zekun Wu Performance Shaping Factors in the Human Error Probability Modification of Human Reliability Analysis. International Journal of Occupational Safety and Ergonomics. 2020;26(3):538–550. https://doi.org/10.1080/10803548.2018.1498655

3. Xing Pan, Ye Lin, Congjiao He. A Review of Cognitive Models in Human Reliability Analysis. Quality and Reliability Engineering International. 2017;33(7):1299–1316. https://doi.org/10.1002/qre.2111

4. Che Haiyang, Zeng Shengkui, Guo Jianbin. Reliability Assessment of Man-Machine Systems Subject to Mutually Dependent Machine Degradation and Human Errors. Reliability Engineering & System Safety. 2019;190(3):106504. https://doi.org/10.1016/j.ress.2019.106504

5. Egelsky VV, Nikolaev NN, Egelskaya EV, Korotkiy AA. Influence of the Competencies of Lifting Crane Specialists on the Probability of Emergencies. Safety of Technogenic and Natural Systems. 2023;(2):70–79. https://doi.org/10.23947/2541-9129-2023-7-2-70-79

6. Egelskaya EV, Romanenko MYu. Aspects of Application of a Risk-Based Approach to Hazardous Production Facilities. Safety of Technogenic and Natural Systems. 2020;(4):45–49. https://doi.org/10.23947/2541-9129-2020-4-45-49

7. Panfilov AV, Deryushev VV, Korotkiy AA. Recommended Safety Systems for Risk-Oriented Approach. Occupational Safety in Industry. 2020;(5):48–55. (In Russ.) https://doi.org/10.24000/0409-2961-2020-5-48-55

8. Pullin R, Holford KM, Lark RJ, Eaton MJ. Acoustic Emission Monitoring of Bridge Structures in the Field and Laboratory. Journal of Acoustic Emission. 2008;26:172–181. URL: https://www.ndt.net/article/ewgae2008/papers/136.pdf (accessed: 15.05.2024).

9. Anastasopoulos AA, Kourousis DA, Cole PT. Acoustic Emission Inspection of Spherical Metallic Pressure Vessels. In: The 2nd International Conference on Technical Inspection and NDT. Tehran, Iran: 2008. URL: http://www.ndt.net/article/tindt2008/papers/177.pdf (accessed: 15.05.2024).

10. Gongtian Shen, Zhanwen Wu. Investigation on Acoustic Emission Source of Bridge Crane. Insight - NonDestructive Testing and Condition Monitoring. 2010;52(3):144–148. https://doi.org/10.1784/insi.2010.52.3.144

11. Aljets D, Chong A, Wilcox S, Holford K. Acoustic Emission Source Location in Plate-Like Structures Using a Closely Arranged Triangular Sensor Array. In: Proceedings of the 29th European Conference on Acoustic Emission Testing EWGAE. Vienna, Austria; 2010. P. 85–98.

12. Rong Chen, Xiao Yang Li, Lin Lin Zhang, Xiang Yu Wang. Numerical Simulation of Spherical Indentation Method to Identify Metal Material Properties. Advanced Materials Research. 2015;(1119):779–782. http://doi.org/10.4028/www.scientific.net/AMR.1119.779

13. Syngellakis S, Habbab H, Mellor BG. Finite Element Simulation of Spherical Indentation Experiments. International Journal of Computational Methods and Experimental Measurements. 2018;6(4):749–763. http://doi.org/10.2495/CMEM-V6-N4-749-763

14. Andrianov EN, Ivanov AN. Topical Problems of Construction and Design of the Gantry Crane Boom Outreach Control Mechanisms. Zhurnal Universiteta Vodnykh Kommunikatsii. 2012;(2):81–92. (In Russ.)

15. Khvan R. Use of Artificial Neural Networks for Solving the Problem of Residual Resource Estimation of Hoisting Cranes. E3S Web of Conferences. 2024;515:04015 https://doi.org/10.1051/e3sconf/202451504015

About the Authors

D. N. SimonovRussian Federation

Dmitry N. Simonov, Chief Designer

88, Troitskaya St., Novocherkassk, 346428

R. V. Khvan

Russian Federation

Roman V. Khvan, Cand. Sci. (Eng.), Associate Professor of the Department of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

E. A. Panfilova

Russian Federation

Elvira A. Panfilova, Cand. Sci. (Philosophy), Associate Professor of the Department of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

L. A. Ternovskoi

Russian Federation

Leonid A. Ternovskoi, Postgraduate Student of the Department of Transport Systems and Logistics

1, Gagarin Sq., Rostov-on-Don, 344003

Review

For citations:

Simonov D.N., Khvan R.V., Panfilova E.A., Ternovskoi L.A. Methodology for Determining the Classification Group of Jib Cranes of Foreign Companies when Assessing Their Technical Condition during Current Sanctions. Safety of Technogenic and Natural Systems. 2025;(2):158-169. https://doi.org/10.23947/2541-9129-2025-9-2-158-169. EDN: LOEFTJ