Scroll to:

Reducing the Risk of Container Overturning under Wind Loads by Improving the Parameters of Railway Platform Stops

https://doi.org/10.23947/2541-9129-2025-9-4-319-330

EDN: OYBJCC

Abstract

Introduction. The problem of containers overturning off railway platforms has become more acute with the development of logistics and climate change, and is attracting the attention of researchers. This paper examines the situations at various logistics facilities and different capacities. It is known how the risk of overturning depends on the strength of the wind, the curvature of the track, and the height of the rail. There are methods to calculate losses from these incidents. The results of the survey are useful for logistics management, but implementing such solutions takes time and significant resources, so they are rarely implemented in practice. The approach described in this article addresses these limitations by its technical simplicity. Its aim is to demonstrate the effectiveness of adjusting three platform parameters: the lateral gap at the edge, as well as the height and thickness of the stationary stops.

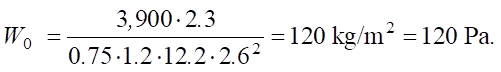

Materials and Methods. The literature on the subject was analyzed, including state standards, technical specifications, and building codes and regulations. The connection between the fitting and the stop, as well as the container's parameters necessary for calculations, were visualized in diagrams. The equations took into account the strength of the wind, its lateral load on the container, and regional characteristics. We used data on a 40-foot container with dimensions of approximately 12.2 meters in length, 2.6 meters in height, and 3.9 tons in weight, with spacing between fittings of approximately 2.3 meters. Regional wind patterns were determined using the “Zoning of the Territory of the Russian Federation by Wind Pressure” map.

Results. It has been proven that a technically simple change in platform stops would significantly reduce the risks of container overturning under significant wind load. It was necessary to minimize the lateral play at the edge of the platform, increase the height of the stationary stop to 106 mm, and its thickness to 56 mm. Without these upgrades, a 40-foot container would overturn at a wind speed of 120 Pa. With the proposed configuration, the stability of the container on the platform was significantly improved. In dry conditions, the container remained stable under wind forces of »834 Pa, with precipitation — »500 Pa. This represented a gain of 7 times and 4.2 times, respectively, in stability.

Discussion. In the initial configuration, a 40-foot container overturns at a wind speed of 11.9 m/s, or in wind zone I, as in Moscow or Minsk. The modernization proposed by the author will allow the container to withstand wind speeds of 37 m/s (zone VII). In rain and snow, the container will overturn at a wind speed of 29.5 m/s. This is zone IV (Kazakhstan and the coast of the Caspian Sea). Currently, there is active automobile and railway traffic here. Cargo traffic is expected to increase in the future due to the implementation of the Silk Road project.

Conclusion. The implementation of the proposed innovation will significantly reduce the likelihood of emergencies due to containers falling from railway platforms and, consequently, increase transportation safety. The solution is characterized by technological simplicity and versatility. The container design remains the same. Individual elements of the platform change minimally.

Keywords

For citations:

Demyanov A.A. Reducing the Risk of Container Overturning under Wind Loads by Improving the Parameters of Railway Platform Stops. Safety of Technogenic and Natural Systems. 2025;9(4):319-330. https://doi.org/10.23947/2541-9129-2025-9-4-319-330. EDN: OYBJCC

Introduction. The growing problem of modern logistics and the risk of containers falling from railway platforms require theoretical and practical research. Both empty and full containers are not able to withstand strong wind forces. As a result, incidents and accidents on the railway are becoming more common. Here are some resonant examples. On April 22, 2014, eleven containers with a total weight of 20 tons were overturned by the wind in the Yamalo-Nenets Autonomous Okrug1.

On December 29, 2015, on the Vishnevka — Anar section (Karaganda direction), a container fell across the tracks. The traffic of twelve trains was brought to a standstill2.

On August 13, 2016, wind gusts blew seven empty containers off the platform on the Domikan —Arkharinsk section of the Trans-Baikal Railway. Traffic stopped in two directions3.

Experts give two reasons for the increased frequency of such incidents. The first is the growth of railway container traffic. The second is climate change, which has led to increased wind loads.

The strategically important East-West transport corridor runs through Russia, and railway transportation, including container transportation, forms the basis of traffic. Since 2019, their volumes have been growing, even under international sanctions4. In 2022, Russian Railways transported a record 123 million tons of cargo to China5, which was almost a third more than in 2021. And in 2023, this indicator increased by another 85%6.

The high dynamics of traffic volume growth continues. Russian Railways are increasingly working on the Trans-Mongolian route and the transit corridor through Kazakhstan7.

The instability of global logistics, particularly maritime traffic through the Suez Canal, has increased the demand for overland transportation from Asia to Europe through Russia. To fully develop as an alternative, the Russian railway transport system needs to address several challenges. One such challenge is the risks of damage, loss of cargo and delays in delivery caused by containers falling off platforms.

Meteorologists record changes in wind load in different regions of the planet. Previously uncharacteristic hurricanes and tornadoes are increasingly observed in some territories of Russia8. Such weather adversely affects the transport infrastructure, including the railway. It is obvious that overturning containers from platforms reduces the safety of transportation.

According to modern research, about a hundred cases of container overturning occur annually on the roads of Russia under the influence of strong winds. A wind speed of 17 meters per second is enough for a serious incident [1].

In 2024, Russian Railways management ordered that reference and analytical information on the possible strength and intensity of wind on the route should be taken into account when planning transportation9.

When assessing damage caused by fallen containers, it is important to consider not only the damage to the container and its contents, but also the potential consequences of a container falling onto the way. This will almost certainly result in traffic stop losses. However, more serious consequences are possible, for example, in conditions with poor visibility (at night, during fog, etc.). It is especially dangerous if the container falls off the platform on the bridge.

A review of the literature on this issue revealed that researchers have considered the risks of container overturning under various climatic conditions and at structurally and functionally diverse facilities within the global transportation system. For instance, the movement of rail and road transport platforms carrying containers has been studied, as well as the risks associated with containers not moving during loading and unloading operations while waiting.

In [2], the methods for assessing the stability of containers during transportation on specialized railway platforms are discussed. Paper [3] describes the conditions under which empty containers of different types can overturn. It shows how the probability of such an incident depends on the strength of wind, the curvature of the track, and the height of high rails. Methods have also been developed to estimate the economic, financial, and reputational costs associated with these incidents.

In [4], the effects of crosswinds on various types of railway vehicles used for urban and suburban transport are studied. It should be noted that this issue is relevant not only to railway transport, but also to automobile traffic [5]. There have been publications in which authors have determined the minimum speed and angle of the wind relative to the train's direction of movement in the climate conditions of South Australia [6] and Colombia [7], which emphasizes the scale and global significance of the issue.

There are known works on forecasting economic damage caused by disruptions in the operation of ocean container ports due to wind [8], extreme wind events [9]. In [10], methods for modeling the damage to container shipments from wind impacts are presented and the development of long-term weather forecasts is proposed. The results of this study can be extrapolated to the work of other related subjects of port logistics, for example, to companies engaged in the field of freight rail transportation.

A study on improving the safety of water transport in strong wind conditions [11] suggests a comprehensive risk awareness tool for decision makers need to prevent disasters in stormy weather. This approach can be integrated with the principles of safe operation of any transportation system, including railways.

The scientific research described above provides solutions for managerial practice in logistics. These solutions can be useful for solving the problem of container falling off railway platforms. However, the approaches considered are complex or initially stated as part of a large-scale security system. This means that significant financial and time resources are needed to implement them. Improvements are needed, taking into account not only the national specifics, but also the specifics of individual territories through which freight trains with containers travel. Over time, such adapted solutions will undoubtedly appear. In the meantime, some measures can be taken. These measures should be low-cost and easy to implement. The aim of this work is to demonstrate the effectiveness of changing the platform's lateral play, working height, and stationary stop thickness.

Materials and Methods. An analysis of container mounting methods showed that the fitting parameters were uniform and fixed in GOST R 51891-2008, while the designs of the stops were diverse and regulated by various specifications.

The most common designs of stops are listed below:

- stationary stop, welded to the platform frame (Fig. 1);

- folding single welded stop (Fig. 2);

- folding single cast stop (Fig. 3);

- folding double welded stop (Fig. 4);

- folding single stop with additional fastening (Fig. 5).

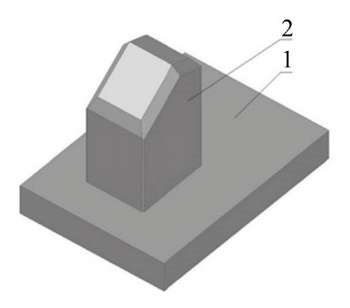

Fig. 1. 31887-NSB non-folding, stationary stop, welded to the platform frame [12]:

1 — base, 2 — stop

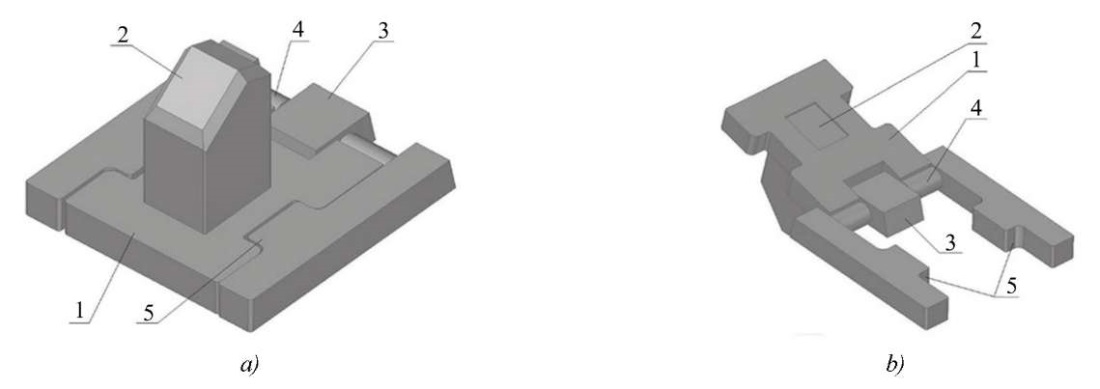

Fig. 2. 31901-NSB single welded folding stop [12]:

a — initial position; b — reclined position;

1 — base of the stop; 2 — stop; 3 — hinge; 4 — axial pin; 5 — stop plate

Fig. 3. 31896-NSB single cast folding stop [12]:

a — initial position; b — reclined position;

1 — stop base; 2 — stop; 3 — base loop; 4 — axial pin; 5 — stop plate; 6 — centering spigot; 7 — stop loops; 8 — recess for centering spigot

Fig. 4. 31883-NSB folding double welded stop [12]:

a — initial position; b — reclined position;

1 — stop base; 2 — stop; 3 — axial pin; 4 — stop plate; 5 — base loop; 6 — holes for stops

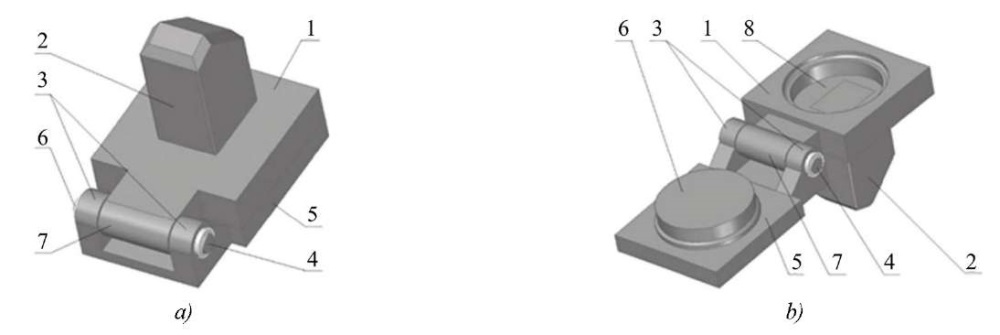

Fig. 5. Single folding stop with additional fastening [12]:

1 — stop plate; 2 — stop base; 3 — stop; 4 — axial pin; 5 — shackle lock; 6 — accidental release lock

Due to lateral play D = 11.5–13.5 mm, the fitting can easily slip off the stop and does not prevent the container from overturning (Fig. 6). If the stops are used without additional fasteners, the container may lose stability from the effects of transverse wind loads, as is known from logistics practice.

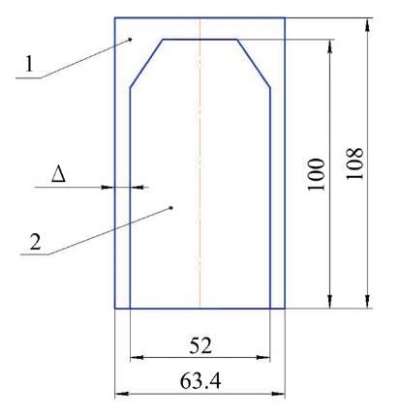

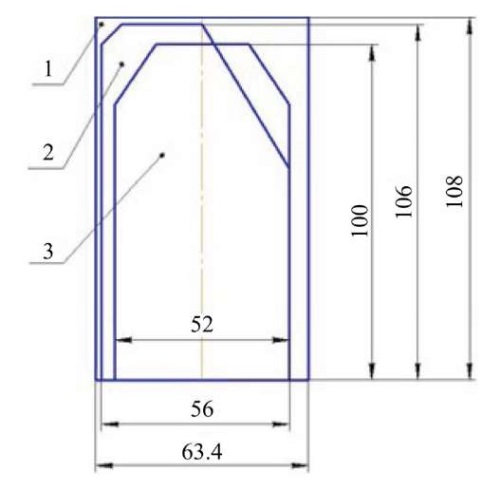

The analysis of serial fitting stop designs revealed that their height was 85–100 mm, thickness — 50–52 mm, and width — 78 mm. The height of the hole for the stop in the fitting was 108 mm, width — 63.5 mm.

Fig 6. Coupling of the fitting and the stop in the cross section:

1 — size of the fitting hole; 2 — size of the stop

Let us evaluate the stability of the container on the stops of the original structure. The conditions are:

- transportation of an empty container in a straight line;

- wind load is transverse to the movement direction.

Let us perform the calculation for the most common type of stop — 31887-NSB stationary non-folding stop (Fig. 7).

Fig. 7. Stationary stop for the container

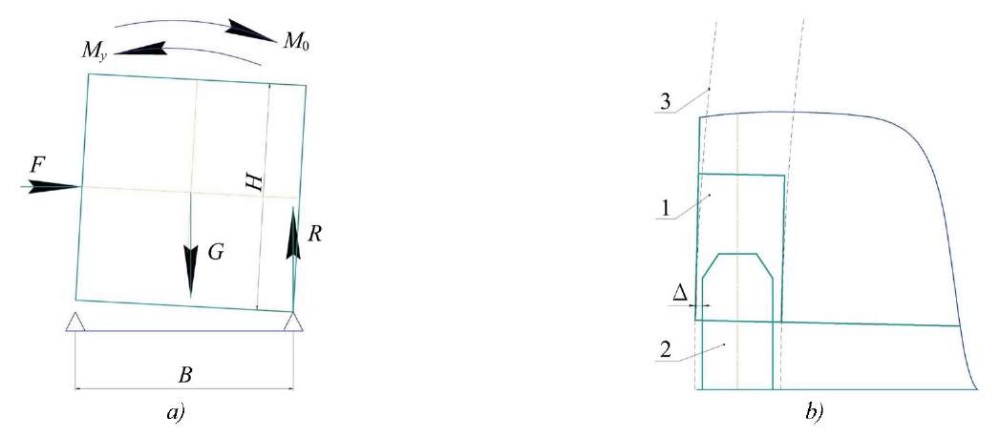

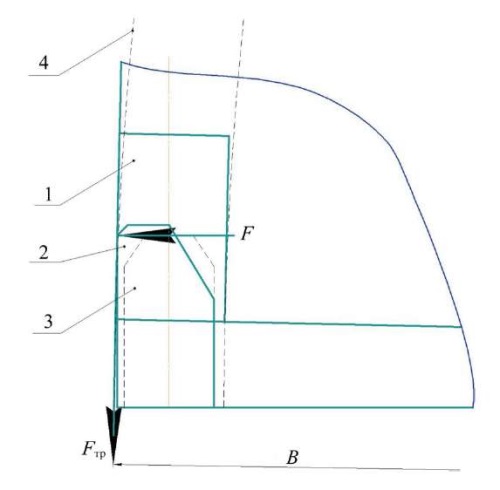

In the absence of additional fasteners, stability can be found from the equality of МО overturning moment and МУ stabilizing moment (Fig. 8).

Fig. 8. Cross section of the container:

a — design diagram; b — gap between the fitting and the stop when overturning;

1 — fitting hole; 2 — stop; 3 — trajectory of movement when overturning

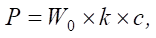

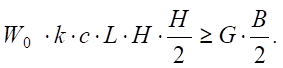

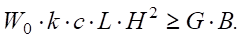

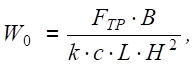

If the center of gravity is in the middle between the stops, then the stabilizing moment is:

where G — mass of the empty container, kg; B — container width, m.

If the tilting force is in the middle of the height of the container, then the overturning moment is:

where F — lateral force of the wind on the container wall, kg; H — height of the container, m.

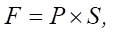

The wind force can be determined from the ratio:

where Р — wind load, kg/m²; S = L × H — side wall area of the container; L — length of the container, m.

The wind pressure, according to Construction Standards and Regulations 2.01.07-8510 and 20.13330.201611, is determined as follows:

where W0 — standard wind pressure for a certain region, k — standard coefficient of wind pressure adjustment taking into account the height and ground profile, с — object aerodynamics coefficient.

Let us transform the original formulas:

Let us simplify it:

Let us transform the resulting expression:

Let us perform the calculation using the example of a 40-foot container dimensions L»12.2 m, H»2.6 m and a weight of G = 3900 kg. According to GOST R 51891-2008, the spacing between the fittings is B»2.3 m (Fig. 8). The calculations are conducted for open space (SNiP 2.01.07-85 and SP 20.13330.2016).

Since the upper size of the container is 5.2 m, we will use the wind pressure correction factor k = 0.75.

Given that the ratio of the length to height of the object exceeds 4, the aerodynamic coefficient will be с = 1.2 (in accordance with SP 20.13330.2016).

We can estimate the threshold value of wind pressure velocity that could potentially overturn an empty 40-foot container as follows:

According to SP 20.13330.2016, this corresponds to a wind speed of approximately 11.9 m/s.

The obtained values allow us to conclude that safety is not ensured even in the I wind zone (Table 1), which includes, for example, Moscow, Minsk, etc.

Table 1

Standard wind pressures depending on the wind area according to SP 20.13330.2016

|

Wind regions of Russia |

Ia |

I |

II |

III |

IV |

V |

VI |

VII |

|

W0, kPa (kg s/m²) |

0.17 (17) |

0.23 (23) |

0.30 (30) |

0.38 (38) |

0.48 (48) |

0.60 (60) |

0.73 (73) |

0.85 (85) |

According to the average data12 the wind speed in the north of Russia is 28–35 m/s, in the Far East — 31–38 m/s, in the North Caucasus — 28–31 m/s. At the same time, wind gusts in these regions can exceed 40 m/s.

The level of stability and safety for container transportation increases directly with the workload. Therefore, the risks for empty containers are the highest.

A significant amount of cargo traffic passes through areas with strong wind pressure, zones III and IV (Fig. 9). This means that there is a risk of containers overturning during the majority of transportation journeys. Additionally, many containers travel from Europe to China without cargo [2].

Fig. 9. Wind loads in different regions of Russia

To solve the problem of containers being overturned by the wind, a proposal has been made to equip the platforms with additional locking mechanisms [13] or additional retaining elements [14].

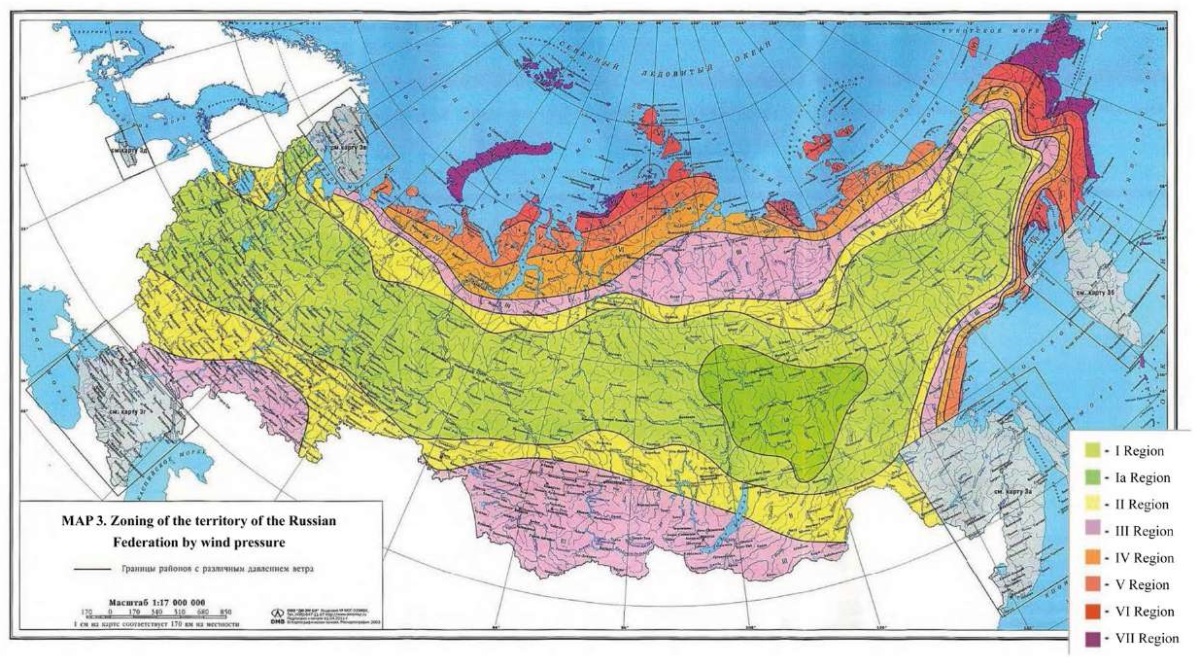

In the first option, additional assemblies would be placed under each container. It is a shaft transverse to the axis of movement of the car. At each end of the shaft, there would be a lever. One lever would press against the container, while the other lever would turn under the force of that pressure, helping to keep the container from overturning (Fig. 10).

Fig. 10. Torsion shaft with levers [12]: A — retaining rotary levers

The second technical solution involves the use of locking devices under each container in the form of additional pins. These pins must be positioned with a minimum clearance to ensure that the container can be moved vertically when placed and removed from the platform (Fig. 11).

Fig. 11. Locking device [13]:

a — schematic representation; b — place on the platform

It should be noted that modernizing standard cars with new components will require significant financial investment. In addition, there is a possibility of misalignments due to wind gusts or incorrect actions by the crane operator. When installed on a platform in a transverse plane, the shaft levers may rotate asynchronously, which can lead to deformation or breakage of the components. These are the weaknesses of the first option.

The main disadvantage of the second solution is its structural inefficiency. It can be seen as an unnecessary complication of the design with several parallel elements (a stop and an external pin) that perform the same function. Additionally, as in the first case, implementation involves significant financial, material, and time costs.

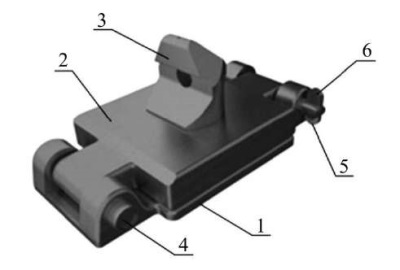

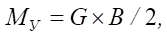

Results. In this paper, we propose to increase the wind resistance of containers on railway platforms without resource-intensive changes to the design of the cars and containers. The problem can be solved by adjusting three parameters (Fig. 12):

- increasing the working height of the stationary stop welded to the car frame from 85–100 mm to 106 mm;

- increasing the thickness of the stop from 50–52 mm to 56mm;

- reducing the lateral play at the edge of the platform from 11.5–13.5 mm to a minimum technically feasible value;

- the width remains standard — 78 mm.

Fig. 12. Dimensions of the modified stop:

1 — size of the fitting hole; 2 — size of the modified stop; 3 — size of the initial stop

This approach will reduce the play of the container on the stops in the transverse plane from the edge of the platform.

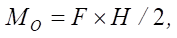

As soon as the container begins to tilt, the stop will become jammed in the fitting due to the decreased external gap (Fig. 13).

Fig. 13. Contact of the fitting surfaces and the modified stop when the container starts to overturn:

1 — fitting hole; 2 — modified stop; 3 — initial stop; 4 — trajectory of movement when overturning

It should be noted that the suggested maximum height of 106 mm should not be exceeded, as the container will then not be supported by the base of the platform. Instead, it will rest on relatively small stops, which could negatively affect stability. A recommended thickness of 56 mm, in terms of proportion, would fit well with a height of 106 mm

The container will be held by the frictional force FТР. The limiting value of this force will depend solely on the stiffness of the stop. When the container bends under the load, the normal reaction from the support will decrease. This will cause the fitting to slip off the stop, and the container may overturn.

The effectiveness of the solution was determined by calculating the bending stop in the fitting and the maximum normal reaction force F between the interacting surfaces when the stop in the fitting is jammed.

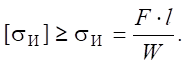

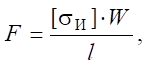

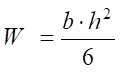

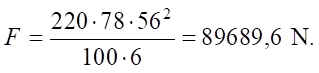

Stops are often made of 10KhSND steel with allowable bending stresses of [sИ] = 220 MPa:

Here l — height of the force applied to the stop from contact with the fitting. It is equal to 100 mm, however, taking into account chamfers and other elements, the working height is 106 mm, i.e. the maximum recommended in the framework of this scientific work.

This means,

where  — moment of stop resistance.

— moment of stop resistance.

If the stop width h = 78 mm, and its thickness b = 56 mm, then:

Thus, before the start of noticeable deformation, the stop will formally withstand 89.7 kN.

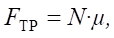

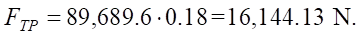

Let us calculate the additional friction holding force that occurs due to dry and rainy weather conditions.

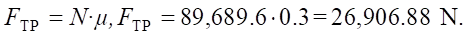

According to TU No. TsM-943 dated October 23, 201713, the coefficient of friction at rest between steel surfaces cleaned of dirt and snow should be assumed to be 0.3.

In this case, the friction force of the stop on the fitting is:

where m = 0.3 — coefficient of friction of steel on steel, N = F — normal pressing force of the surfaces.

Let us substitute the known values:

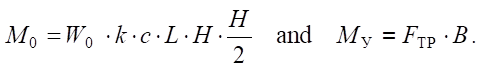

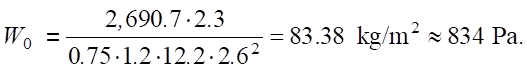

Let us evaluate the effectiveness of the proposed solution by considering the wind load that can overcome the holding moment and cause the container to overturn:

(1)

(1)

where FТР — friction force on the surface of the fitting and the stop; В — application shoulder, i.e. the width of the container along the axes of the fittings.

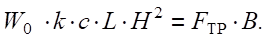

Let us write down the ratio of moments:

(2)

(2)

This means:

(3)

(3)

The value of the wind load:

(4)

(4)

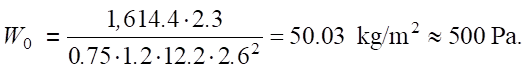

In wind and rain, the friction coefficient between the stop and the fitting is 0.15–0.2. For the purpose of this calculation, let us use an average value of 0.18.

Let us evaluate the effectiveness of the proposed wind load solution for this situation, which can overcome the stabilizing moment and overturn the container. We use expressions (1)–(4). We get:

Discussion. Thus, a stop with a height of 106 mm, width of 78 mm, and thickness of 56 mm will formally withstand an impact of approximately 90 kN (the exact figure is 89.7 kN) before it begins to visibly deform. Therefore, 89.7 kN represents the maximum normal force that can be exerted between the friction surfaces.

Calculations have shown that a 40-foot container could overturn with a wind load of 120 Pa in the initial configuration. This corresponds to a wind speed of 11.9 m/s, which is typical for wind zone I, such as in Moscow and Minsk, for example. An empty container can also tip over under the influence of wind loads on a stationary platform.

The solution proposed by the author will allow the container to stand on a moving platform with a wind load of about 834 Pa. This corresponds to a wind speed of about 37 m/s, typical for the wind zone VII. Obviously, the indicator will be lower for wind and rain conditions, and calculations have confirmed this. The container will tip over at a load of approximately 500 Pa. This corresponds to a wind speed of about 29.5 m/s, which is typical for the wind zone IV, which includes, for example, Kazakhstan and the coast of the Caspian Sea. Currently, there is active automobile and railway traffic there. Cargo traffic is expected to increase in the future due to the implementation of the global multimodal transport project Silk Road.

The proposed approach to addressing the issue of wind stability for containers in this study is calculated with regard to fixed, stationary stops, which eliminate the possibility of any movement. The calculation is based on an example of a 40-foot container, although the principle can be applied to other form factors.

Conclusion. The proposed solution in real-world transportation conditions (including in windy and rainy weather) will increase the stability of containers on the platform from tipping over due to wind. The calculations primarily took into account data from the wind zones I–IV, as these are the areas where goods are actively moved. However, even in dry weather and in the area with the strongest winds — VII, upgrading the platform would still be beneficial.

The implementation of the proposed innovation will significantly reduce the likelihood of emergencies related to containers falling from railway platforms, and, accordingly, will increase transportation safety.

The solution is characterized by its technological simplicity and versatility. The container design remains unchanged, with only minor adjustments to individual elements of the platform.

1. In Yamalo-Nenets Autonomous District, 11 containers with cargo tipped over due to strong winds. (In Russ.) URL: https://life.ru/p/131740

(accessed: 08.11.2025).

2. In Akmola region, a container was blown off a freight train by a strong wind. (In Russ.) URL: https://www.zakon.kz/proisshestviia/4766046-v-karagandinskojj-oblasti-silnym-vetrom.html (accessed: 08.11.2025).

3. On the movement of trains on the Arkhara — Domikan section of the Svobodny region of the Trans-Baikal Railway. (In Russ.) URL: https://zabzd.rzd.ru/ru/2332/page/2452802?id=90092 (accessed: 08.11.2025).

4. The Russian container transportation market has a threefold potential for growth. (In Russ.) URL: https://www.megaresearch.ru/new_reality/u-rynka-konteynernyh-perevozok-rossii-est-trehkratnyy-potencial-dlya-rosta (accessed: 08.11.2025).

5. In 2022, Russian Railways increased cargo transportation with China by 28%, to 123 million tons. (In Russ.) URL: https://www.interfax.ru/business/886341 (accessed: 08.11.2025).

6. Russian Railways increased cargo transportation with China by almost 1.9 times in January-February. (In Russ.) URL: https://www.interfax.ru/business/892180 (accessed: 08.11.2025).

7. Id.

8. Gubaeva L. How the climate of Russia will change in the 21st century and why it is necessary to get used to weather anomalies. Real time. (In Russ.) URL: https://m.realnoevremya.ru/articles/184780-kak-globalnoe-izmenenie-klimata-otrazitsya-na-rossii-v-xxi-veke (accessed: 08.11.2025).

9. Russian Railways. Order No. 2115p dated October 19, 2016. On approval of the Procedure for organizing the safe passage of freight trains with empty containers when predicting a dangerous weather event along their route. (In Russ.) URL: https://docs.cntd.ru/document/456030815 (accessed: 08.11.2025).

10. SNiP 2.01.07-85*. Loads and impacts. (In Russ.) URL: https://www.minstroyrf.gov.ru/docs/13673/ (accessed: 08.11.2025).

11. SP 20.13330.2016. Set of rules. Loads and impacts. Updated version of SNiP 2.01.07-85*. (In Russ.) URL: https://mchs.gov.ru/uploads/document/2022-03-15/079727a84b6dfc87f4f6c2db1a5693ed.pdf (accessed: 08.11.2025).

12. Shoigu SK, Trokhina NB. (eds.) Atlas of natural and man-made hazards and risks of emergency situations in the Russian Federation. Moscow: DIK; 2005. P. 269. (In Russ.)

13. Technical Conditions for the Placement and Fastening of Goods in Cars and Containers. Ministry of Railways of the Russian Federation. May 27, 2003 No. CM-943. (In Russ.) URL: https://company.rzd.ru/ru/9353/page/105104?id=1341 (accessed: 09.11.2025).

References

1. Popov VG, Matesheva AV, Sukhov PI, Bolandova YuK. Conditions Leading to Overturning of Empty Containers under the Influence of Wind Load. World of Transport and Transportation. 2019;17(6):50–61. (In Russ.) https://doi.org/10.30932/1992-3252-2019-17-50-61

2. Bolandova YuK. Methods for Assessing Stability from Container Overturning during Transportation on Specialized Railway Platforms. Cand. Sci. (Eng.) diss. Moscow; 2021. 153 p. (In Russ.)

3. Popov VG, Sukhov PI, Bolandova YuK. Transport Safety Culture. World of Transport and Transportation. 2019;17(2):206-217. (In Russ.) https://doi.org/10.30932/1992-3252-2019-17-2-206-217

4. Giappino S, Rocchi D, Schito P, Tomasini G. Cross Wind and Rollover Risk on Lightweight Railway Vehicles. Journal of Wind Engineering and Industrial Aerodynamics. 2016;153:106–112. https://doi.org/10.1016/j.jweia.2016.03.013

5. Baker C, Cheli F, Orellano A, Paradot N, Proppe C, Rocchi D. Cross-Wind Effects on Road and Rail Vehicles. Vehicle System Dynamics. 2009;47(8):983–1022. https://doi.org/10.1080/00423110903078794

6. Simes T. A Blow to Train Operations, Can Strong Winds Cause Derailment? In: International Railway Safety Conference. Melbourne, 2017. URL: https://international-railway-safety-council.com/wp-content/uploads/2017/09/simes-a-blow-to-train-operations-can-strong-winds-cause-derailment.pdf (accessed: 09.11.2025).

7. Piñeres Castillo AP, Mojica Herazo JC. A Review of Wind Impact on Container Port Operations: Current Technologies, Strategies and Future Perspectives. Procedia Computer Science. 2024;251:783–788. https://doi.org/10.1016/j.procs.2024.11.185

8. Yi Zhang, Cai Wei, Zhonghui Shen, Xiwen Bai, Xinzheng Lu, Guedes Soares C. Economic Impact of Typhoon-Induced Wind Disasters on Port Performance: A Case Study of Chinese Ports. International Journal of Disaster Risk Reduction. 2020;50:101719. https://doi.org/10.1016/j.ijdrr.2020.101719

9. Yi Zhang, Jasmine Siu Lee Lam. Estimating the Economic Losses of Port Disruption Due to Extreme Wind Event. Ocean & Coastal Management. 2015;116:300–310 https://doi.org/10.1016/j.ocecoaman.2015.08.009

10. Xinhu Cao, Jasmine Siu Lee Lam. Simulation-Based Catastrophe-Induced Port Loss Estimation. Reliability Engineering & System Safety. 2018;175:1–12 https://doi.org/10.1016/j.ress.2018.02.008

11. Ricci A, Vasaturo R, Blocken B. An Integrated Tool to Improve the Safety of Seaports and Waterways under Strong Wind Conditions. Journal of Wind Engineering and Industrial Aerodynamics. 2023;234:105327. https://doi.org/10.1016/j.jweia.2023.105327

12. Dyatlova OA. Determination of Common Features and Classification of Fitting Stops for Flat Cars. Transport Technician: Education and Practice. 2021;2(3):339–346. (In Russ.) https://doi.org/10.46684/2687-1033.2021.3.339-346

13. Boronenko YuP, Dauksha AS. Selecting Design Solutions for Container and Swap Body Flatcar Fixing Devices. Transport of the Russian Federation. 2017;3(70):29–32. (In Russ.)

14. Boronenko YuP, Polyakov BO, Polyakova EYa. Impact of Lateral Wind Forces on Double Stack Container Transportation. Transport of the Russian Federation. 2023;(1–2):41–45. (In Russ.) https://rostransport.elpub.ru/jour/article/view/39/39?ysclid=miigx9qlyr761273545 (accessed: 09.11.2025).

About the Author

A. A. DemyanovРоссия

Aleksey A. Demyanov, Cand. Sci. (Eng.), Associate Professor, Associate Professor of the Department of Transport Systems and Logistics

ElibraryID: 310034

ScopusID: 57195919045

1, Gagarin Sq., Rostov-on-Don, 344003

A new engineering method has been proposed to improve the stability of containers. The method involves adjusting the lateral play and size of the stationary platform stops. Theoretically, a multiple reduction in the risk of container overturning due to wind is justified. Modernization has been shown to significantly increase stability in both dry and wet weather. The solution is technologically simple and does not require any modification to the container design. The results have the potential to improve the safety of freight rail transport.

Review

For citations:

Demyanov A.A. Reducing the Risk of Container Overturning under Wind Loads by Improving the Parameters of Railway Platform Stops. Safety of Technogenic and Natural Systems. 2025;9(4):319-330. https://doi.org/10.23947/2541-9129-2025-9-4-319-330. EDN: OYBJCC

JATS XML