Scroll to:

Influence of Pre-Carburization on the Structure and Properties of Chromium Coatings on Steels Formed by Diffusion Alloying in Liquid Metal Media Solutions

https://doi.org/10.23947/2541-9129-2025-9-2-170-178

EDN: WDDMOV

Abstract

Introduction. Diffusion alloying from the medium of low-melting liquid metal solutions (DALMMS) allows us to form coatings for metal products. At the same time, the carbon content in the alloy is reduced under the carbide coating layer, which negatively affects the operation of products under contact stresses. To neutralize decarburization, as well as to obtain deep hardened layers, a complex chemical-thermal treatment (CCTT) is proposed. It means pre-carburization and subsequent DALMMS with chromium. It is important to compare the characteristics of coatings on metal samples that have undergone and have not undergone carburization. The results of such studies have not been published before. The aim of the work is to analyze the effect of pre-carburization on chromium-based diffusion coatings and the structure of the coated sample.

Materials and Methods. The coatings were obtained by immersing St3 and 40X steel samples in a PbLi reaction transport medium with the addition of chromium. Some of the samples were previously subjected to vacuum carburization. The coating thickness and structure of the coated sample were determined using a universal microscope NU-2E (Carl Zeiss Jena). Electron microprobe analysis was performed on a Tescan Lyra 3 electron microscope with the Oxford Ultim MAX PCMA system. Microhardness was determined by the Dura Scan Falcon 500 microhardness tester. X-ray phase analysis (XPA) was performed on a Bruker D8 Advance Eco X-ray diffractometer.

Results. Without carburization, a coating with a thickness of 12 µm was formed on the St3 steel sample, while with carburization it was 22 µm. The difference was 1.83 times. The chromium diffusion depth in the sample without carburization was 18 µm. In the sample with pre-carburization it was 34 µm. Carburization provided a significant increase in the depth of the hardened layer. Without pre-treatment, the microhardness values of the coating were recorded after DALMMS: 1400 HV0.02 for St3 and 1650 HV0.02 for 40X. After CCTT: 1500 HV0.02 for St3 and 1800 HV0.0 for 40X. However, at a depth of 10 µm, the microhardness (160 HV0.02) was lower than that of the coated material for both samples. After CCTT, the areas with reduced microhardness disappeared, and the depth of the hardened layer was 1.5 mm for St3 and 2 mm for 40X.

Discussion and Conclusion. Pre-carburization helps to avoid the formation of a softened sublayer between the coating and the coated material, which is important for the performance of products under contact stresses. Consequently, chrome-coated structural steel parts can be used after carburization in conditions of abrasive corrosion and high mechanical loads. Examples of these applications include compressor equipment and oil and gas equipment.

Keywords

For citations:

Svistun L.I., Bobylyov E.E., Nirov A.D., Storozhenko I.D., Popov R.A. Influence of Pre-Carburization on the Structure and Properties of Chromium Coatings on Steels Formed by Diffusion Alloying in Liquid Metal Media Solutions. Safety of Technogenic and Natural Systems. 2025;(2):170-178. https://doi.org/10.23947/2541-9129-2025-9-2-170-178. EDN: WDDMOV

Introduction. In modern mechanical engineering, surface hardening of parts is a widely used technique [1]. Known technologies make it possible to obtain products with different properties and structures [2] by changing the properties and structure of the surface layer [3]. Special attention should be paid to chemical and thermal hardening methods. They are characterized by simplicity [4], provide high-quality hardened surfaces [5], as well as a smooth change in structure and properties from coating to coated material [6]. The technology of diffusion alloying from the medium of low-melting liquid metal solutions (DALMMS) refers to the technologies of chemical and thermal treatment (CCTT) and is promising from the point of view of obtaining functional coatings [6]. This technology is used to form coatings based on Cr, Ti, W, Mo, Ni, Cu, etc. on the surface of products made of steels [6], hard alloys [7], and cast iron [8].

Chromium is one of the elements that is often used as a basis for functional coatings [9]. These coatings increase wear resistance of parts [10] and corrosion resistance in aggressive environments [11]. Chrome coatings can also improve resistance to simultaneous complex effects of mechanical and corrosive wear [12]. The high resistance to wear and corrosion is due to the fact that the coatings are based on carbides [13]. During the formation of these carbides, carbon diffuses from the coated material. As a result, the carbon content in the alloy under the coating decreases, leading to the formation of decarbonization zones. This causes the carbide layer to press onto the coated part during operation [14]. To counteract the effect of decarburization and further harden the coated material, complex chemical and thermal treatment (CCTT) can be employed. It means the pre-carburization and diffusion alloying of samples with chromium in the medium of low-melting liquid metal solutions [15].

The aim of this research was to analyze the effect of pre-carburization on the formation of chromium-based diffusion coatings and the structure of the coated sample.

Materials and Methods. CCTT and DALMMS were performed on cylindrical samples with a diameter of 20 mm and a length of 30 mm. The samples were made of St3 and 40X steel (Table 1).

Table 1

Chemical composition of the studied materials

|

Steel grade |

Element content, weight % |

|||||||

|

C |

Si |

Mn |

Ni |

S |

P |

Cr |

Cu |

|

|

St3 |

0.14–0.22 |

0.15–0.3 |

0.4–0.65 |

up to 0.3 |

up to 0.05 |

up to 0.04 |

up to 0.3 |

up to 0.3 |

|

40X |

0.36–0.44 |

0.17–0.37 |

0.5–0.8 |

up to 0.3 |

up to 0.035 |

up to 0.035 |

0.8–1.1 |

up to 0.3 |

Chrome coatings were obtained through the process of diffusion alloying of samples in low-melting liquid metal solutions. To do this, we used the DALMMS setup [16]. The reaction transport medium was a PbLi eutectic melt, into which 10% chromium powder was added. The coating was applied by immersing and then isothermally exposing the samples in the melt at 1050°C for 8 hours, with argon filling the space above the melt. This process also involved solid-phase diffusion, leading to the formation of solid solutions and chemical compounds.

Prior to the start of DALMMS, in order to saturate the surface layers of steels with carbon, vacuum carburization was performed in a propane-butane mixture at a temperature of 950°C for 8 hours.

The structure of the coated material and the thickness of the coating were studied using a NU-2E universal optical microscope (Carl Zeiss Jena). The microhardness of the samples after DALMMS and CCTT was studied on a Dura Scan Falcon 500 microhardness tester. Electron microprobe analysis was performed on a Tescan Lyra 3 scanning electron microscope with the Oxford Ultim MAX PCMA system. An X-ray diffractometer Bruker D8 Advance Eco (Bruker AXS GmbH) with a θ-θ vertical goniometer was used for X-ray phase analysis (XPA). The samples were etched in a 4% alcohol solution of HNO3.

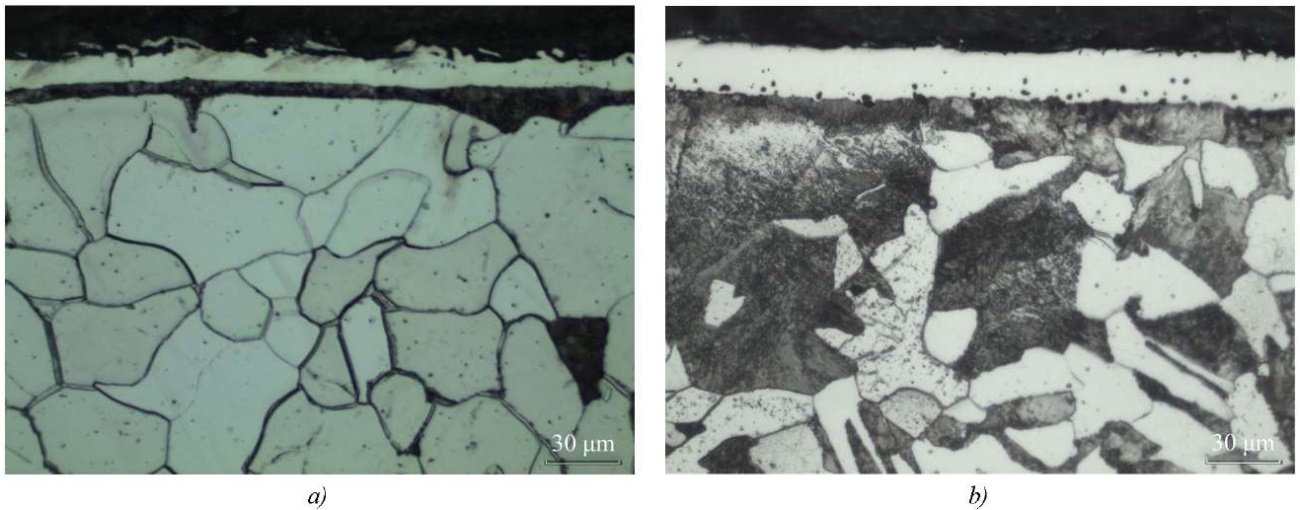

Results. Figure 1 shows micrographs of St3 steel samples after DALMMS and CCTT.

Fig. 1. Surface layers of St3 steel after 8-hour DALMMS at 1050°C:

a — without pre-carburization; b — with pre-carburization

Thus, pre-carburization affected both the steel and coating structure after DALMMS. Without pre-carburization, carbon diffused into the area under the coating, forming a pearlitic layer and a decarbonized ferritic layer in which there were no pearlitic grains. If pre-carburization was performed, the structure of the coated material changed. After CCTT, there was no decarbonized ferritic sublayer in it, even when low-carbon St3 steel was saturated. The structure of the material was perlite with ferrite inclusions (Fig. 1b).

Several zones could be distinguished that formed the surface layers of the material after CCTT:

- coating,

- transition zone between the coating and the material to be coated,

- carburization zone,

- transition carburization zone — base.

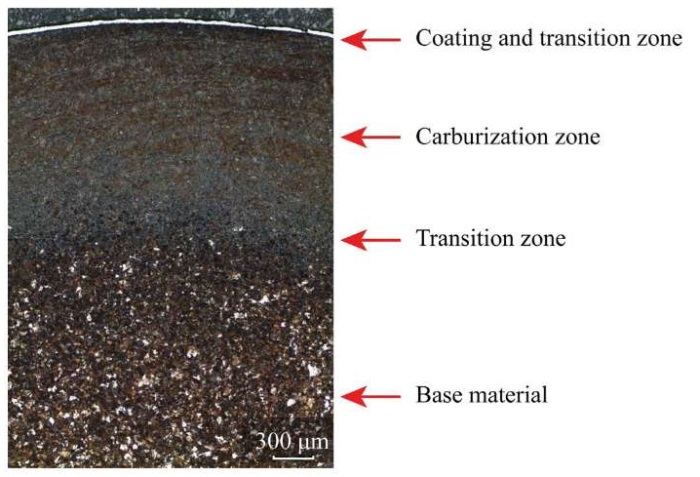

Figure 2 shows the structure of a 40X steel sample after CCTT.

Fig. 2. Sample structure after CCTT

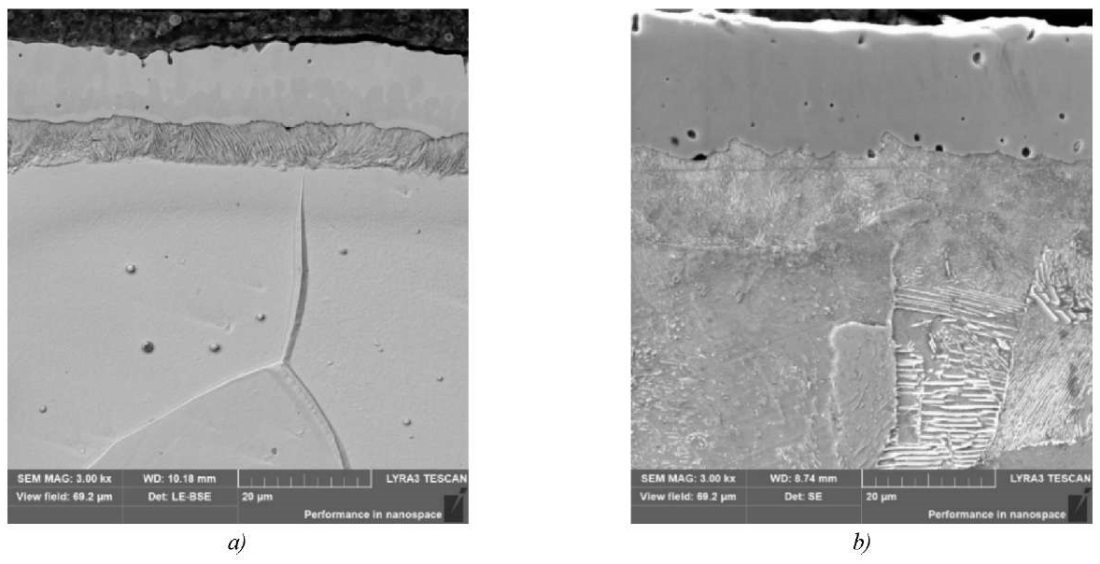

In case of DALMMS without pre-carburization, a zone of lamellar perlite alloyed with chromium was formed under the coating, followed by a soft ferritic layer. There was no decarbonized layer in the pretreated samples. Without carburization, a coating with a thickness of 12 µm was formed on the St3 steel sample; with carburization it was 22 µm. Thus, pre-carburization helped to increase the coating thickness by 1.83 times. There was a physical explanation for this result. Pre-carburization increased the intensity of carbon diffusion from the sample to the adsorbed chromium. Carbon heterodiffusion was recorded under the influence of high temperatures characteristic of DALMMS. This helped to equalize the carbon content and eliminate decarbonized zones that could occur as a result of the formation of carbides. Figure 3 shows micrographs of 40X steel after DALMMS and CCTT. On the sample after CCTT, the perlite structure was thinner, and there was no decarbonized zone.

Fig. 3. The structure of the 40X steel surface layer after an 8-hour DALMMS at 1050°C:

a — DALMMS; b — CCTT

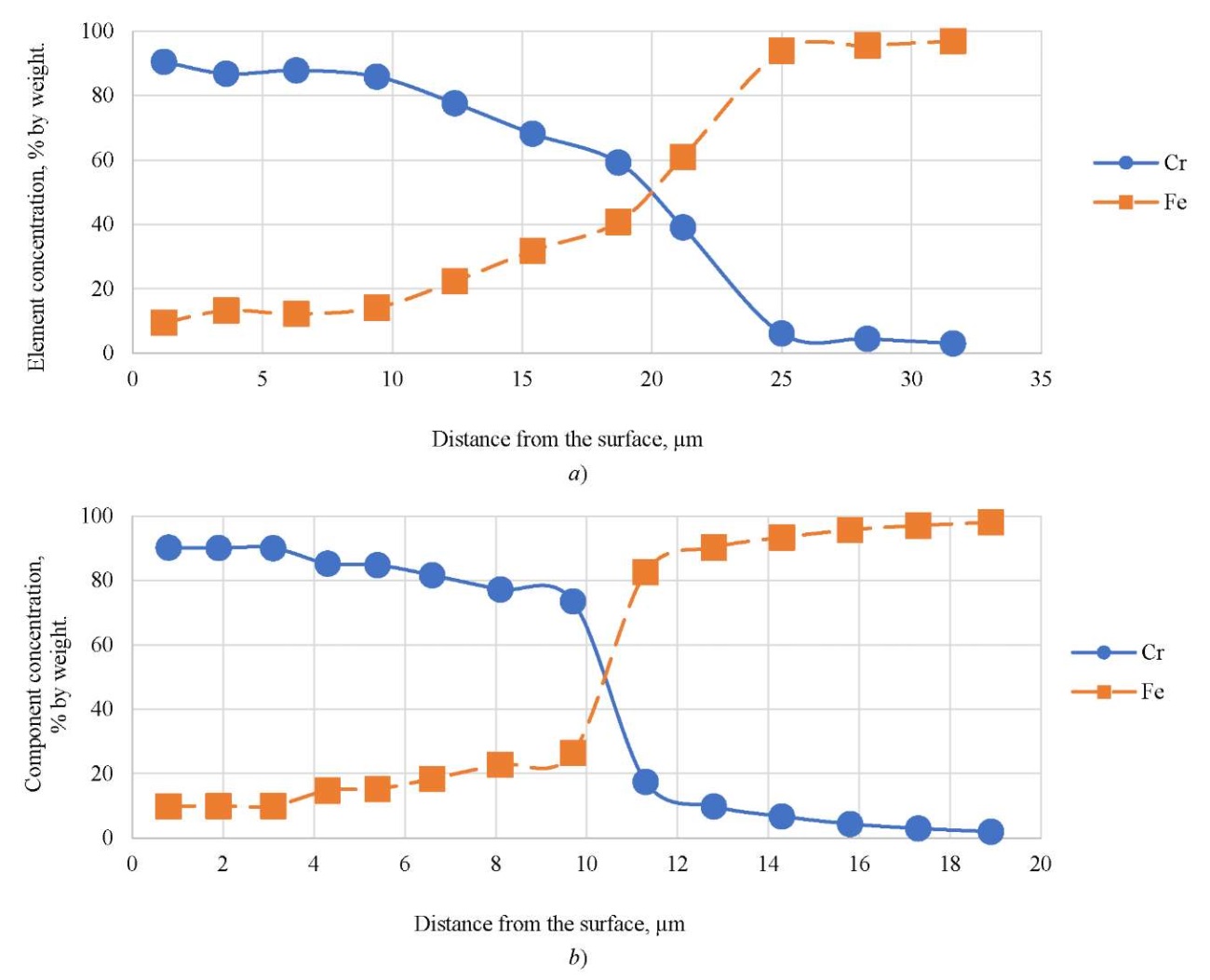

Carburization did not significantly affect the chemical and phase composition. In both cases, the chromium content on the surface was 90% (wt.). However, the depth of chromium diffusion in the sample without carburization was 18 µm. In the sample with pre-carburization it was 34 µm, that is, twice as much. The results of electron microprobe analysis of the samples are shown in Figure 4.

Fig. 4. The results of electron microprobe analysis of coatings after an 8-hour DALMMS at 1050°C:

a — without pre-carburization; b — with pre-carburization

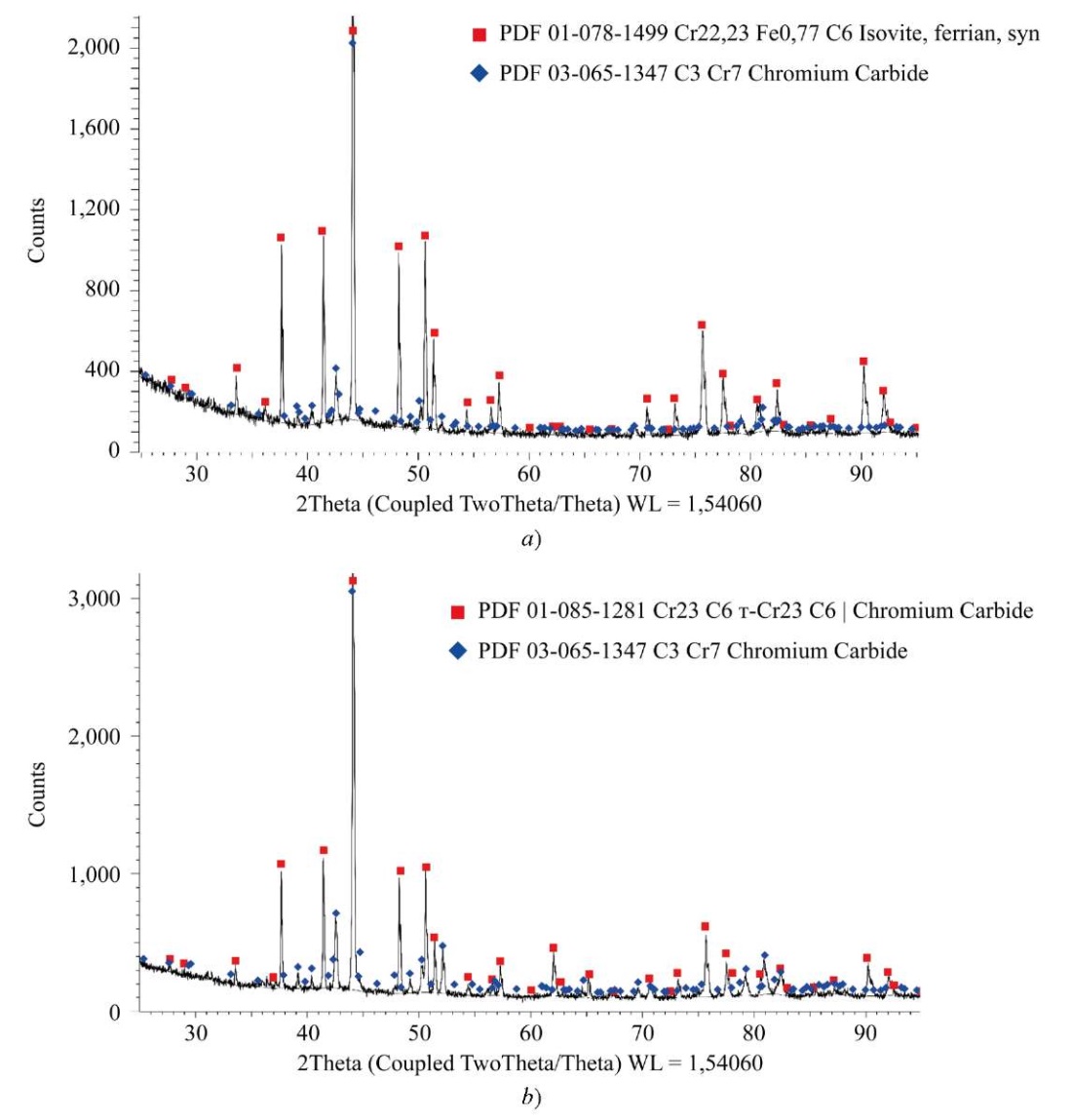

Phase composition of the coatings was represented by chromium carbides M23C6 and M7C3. In the sample without pre-carburization, there was a slight iron content in chromium carbide M23C6 (Fig. 5).

Fig. 5. The results of X-ray phase analysis of the coatings after 8-hour DALMMS at 1,050°C:

a — without pre-carburization; b — with pre-carburization

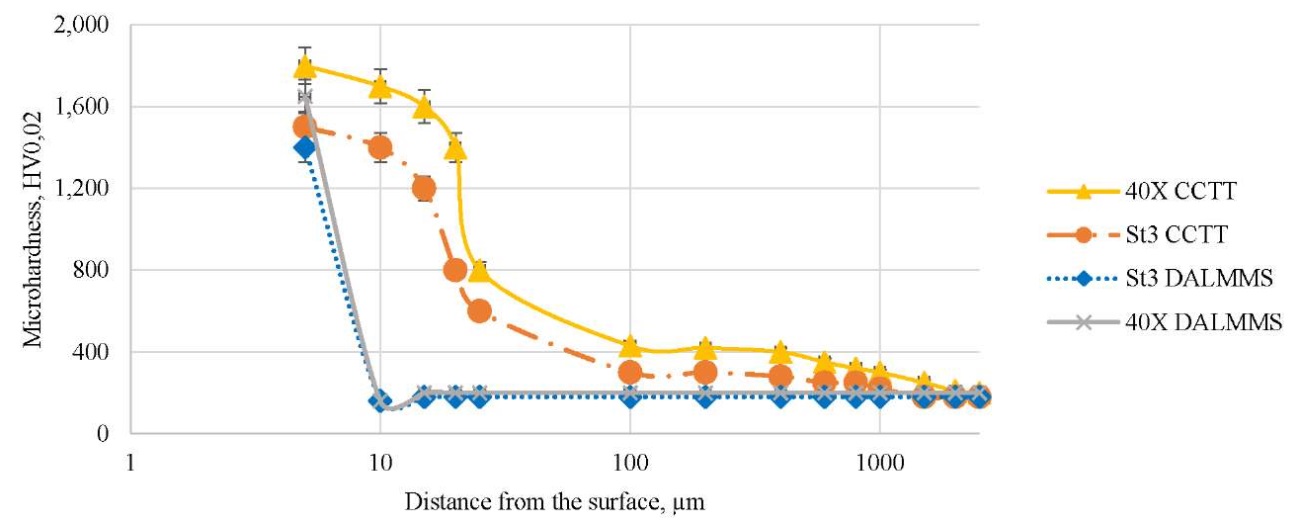

Pre-carburization provided a significant increase in the depth of the hardened layer (Fig. 6).

Fig. 6. Distribution of microhardness in samples after 8-hour DALMMS at 1050°C

According to Figure 6, on samples without pre-carburization, the microhardness index of the coating after DALMMS for St3 steel was 1400 HV0,02, 40Х — 1650 HV0,02. After CCTT, the microhardness of the St3 steel coating was 1500 HV0,02, 40Х — 1800 HV0,0. However, at a depth of 10 µm, the microhardness was 160 HV0,02. This was lower than the microhardness of the coated material in both cases (i.e. for St3 and 40X samples). After CCTT, the microhardness distribution had a different character:

- there were no zones with reduced microhardness,

- the depth of the hardened layer was 1.5 mm for St3 steel and 2 mm for 40X steel.

Discussion and Conclusion. Thus, under the conditions considered, the main effect of carburization was manifested in the intensification of coating growth and the exclusion of the formation of a soft ferritic layer between the coating and the coated material. The composition of the coating and the chromium content did not depend on carburization. In any case, the coatings consisted of chromium carbides such as M23C6 and M7C3, the chromium content on the surface reached 90%.

CCTT affected the structure of the layer between the coating and the base material. In case of DALMMS, the layer under the coating had a pearlitic structure, turning into a ferritic one and further into the structure of the coated material. Pre-carburization made the transition zone more uniform. Here, a pearlitic structure was formed with a gradual change in chromium concentration — from 10% at the boundary of the coating and the pearlitic zone to 0.3% at a depth of 35 µm.

Thus, the positive results of pre-carburization have been proven. Firstly, the carbon content in the surface layers of the product increased, and this made it possible to intensify carburization.

Secondly, it became possible to obtain a carbon-saturated layer between the coating and the base material, which also strengthened the structure of the coated material. Therefore, it can be argued that pre-carburization is promising in terms of expanding the scope of application of parts with diffusion coatings based on chromium carbide. It eliminates the penetration of the layer under the coating and its subsequent destruction. The parts after CCTT are capable of operating at high contact stresses without chipping the functional layer.

Thirdly, the formation of a diffusion coating is accelerated. In addition, it will be thicker. As part of this study, the indicator was 1.83. The coating obtained after carburization was that much thicker (compared with the technology without pre- carburization). This indicates the significant role of carbon in the mechanism of coating creation.

References

1. Xiang Hou, Hao Wang, Qun Yang, Yanxia Chen, Linjiang Chai, Bo Song, et al. Microstructure and Properties of Cr-AlN Composite Coating Prepared by Pack-Cementation on the Surface of Al-Containing ODS Steel. Surface and Coatings Technology. 2022;447:128842. https://doi.org/10.1016/j.surfcoat.2022.128842

2. Vikrant Singh, Anil Kumar Singla, Anuj Bansal. Impact of HVOF Sprayed Vanadium Carbide (VC) Based Novel Coatings on Slurry Erosion Behavior of Hydro-Machinery SS316 Steel. Tribology International. 2022;176:107874. https://doi.org/10.1016/j.triboint.2022.107874

3. Jing Liang, Ye Liu, Sheng Yang, Xiuyuan Yin, Suiyuan Chen, Changsheng Liu. Microstructure and Wear Resistance of Laser Cladding Ti-Al-Ni-Si Composite Coatings. Surface and Coatings Technology. 2022;445:128727. https://doi.org/10.1016/j.surfcoat.2022.128727

4. Zheng Q, Guryev MA, Ivanov SG, Mei S, Guryev AM. Effect of Boron – Chromium – Lanthanum Diffusion Coating on the Heat Resistance and Wear Resistance of 4Kh5MF1S Steel. Bulletin of the Siberian State Industrial University. 2024;3(49):22‒29. (In Russ.) http://doi.org/10.57070/2304-4497-2024-3(49)-22-29

5. Yusuf Kayali, Afra Kenar. Effect of Diffusion Annealing on Wear and Cohesion Behaviours of Boronized AISI 1040 Steel. Tribology International. 2023;184:108428. https://doi.org/10.1016/j.triboint.2023.108428

6. Pryakhin EI, Mikhailov AV, Sivenkov AV. Technological Features of Surface Alloying of Metal Products with Cr – Ni complexes in the medium of Low-Melting Metal Melts. Ferrous Metals 2023;2:58–66. (In Russ.) URL: https://rudmet.ru/journal/2191/article/36387 (accessed: 27.11.2024).

7. Sokolov AG, Mansia S. A Method of Machining a Steel or Carbide Tool. RF Patent, No. 2451108. 2012. 5 p. (In Russ.)

8. Sokolov AG. Krainev NA. Method of Machining of Cast Iron Products. RF Patent, No. 2451108. 2012. 5 p. (In Russ.)

9. Fedrizzi L, Rossi S, Bellei F, Deflorian F. Wear-Corrosion Mechanism of Hard Chromium Coatings. Wear. 2002;253(11/12):1173–1181. https://doi.org/10.1016/S0043-1648(02)00254-5

10. Maskavizan AJ, Quintana JP, Dalibón EL, Márquez AB, Brühl SP, Farina SB. Evaluation of Wear and Corrosion Resistance in Acidic and Chloride Solutions of Cathodic Arc PVD Chromium Nitride Coatings on Untreated and Plasma Nitrided AISI 4140 Steel. Surface and Coatings Technology. 2024;494(3):131476. https://doi.org/10.1016/j.surfcoat.2024.131476

11. Castillejo FE, Marulanda DM, Olaya JJ, Alfonso JE. Wear and Corrosion Resistance of Niobium–Chromium Carbide Coatings on AISI D2 Produced through TRD. Surface and Coatings Technology. 2014;254:104–111. https://doi.org/10.1016/j.surfcoat.2014.05.069

12. Mohammad Reza Najari, Seyed Abdolkarim Sajjadi, Omid Ganji. Microstructural Evolution and Wear Properties of Chromium Carbide Coating Formed by Thermo-Reactive Diffusion (TRD) Process on a Cold-Work Tool Steel. Results in Surfaces and Interfaces. 2022;8:100059. https://doi.org/10.1016/j.rsurfi.2022.100059

13. Beck K, Ulrich AS, Thor N, Oskay C, Galetz MC. Chromium Diffusion Coatings for Improving the Oxidation Behavior of Refractory Metals at Intermediate Temperatures. International Journal of Refractory Metals and Hard Materials. 2024;121:106626. https://doi.org/10.1016/j.ijrmhm.2024.106626

14. Sokolov AG, Artem'ev VP, Shasherina SA. Influence of Steel Carbon and Nature of the Coating Elements on Process and Formation Mechanism of Diffusive Coatings from Fusible Liquid Metal Solutions. Technology of Metals. 2009; 11: 40–44. (In Russ.)

15. Sokolov AG, Artem'ev VP. Steel Article Wear Resistance Increasing Method. RF Patent, No. 2293792. 2007. 4p. (In Russ.)

16. Sokolov AG, Bobylev EE, Storozhenko ID, Popov RA. Device for Diffusion Metallization in Medium of Low-Melting Liquid Metal Solutions. RF Patent, No. 2767108. 2022. 9p. (In Russ.)

About the Authors

L. I. SvistunRussian Federation

Lev I. Svistun, Dr.Sci (Eng.), Professor of the Department of Engineering of Control Systems, Materials and Technologies in Mechanical Engineering

2, Moskovskaya Str., Krasnodar, 350072

E. E. Bobylyov

Russian Federation

Eduard E. Bobylyov, Cand.Sci. (Eng.), Associate Professor of the Department of Engineering of Control Systems, Materials and Technologies in Mechanical Engineering

2, Moskovskaya Str., Krasnodar, 350072

A. D. Nirov

Russian Federation

Aslan D. Nirov, Cand.Sci. (Eng.), Associate Professor of the Department of Transport Processes and Technological Complexes

2, Moskovskaya Str., Krasnodar, 350072

I. D. Storozhenko

Russian Federation

Ivan D. Storozhenko, Senior Lecturer of the Department of Mechanical Engineering, Armavir Institute of Mechanics and Technology

2, Moskovskaya Str., Krasnodar, 350072

R. A. Popov

Russian Federation

Roman A. Popov, Postgraduate Student of the Department of Engineering of Control Systems, Materials and Technologies in Mechanical Engineering

350072, Krasnodar Territory, Krasnodar, Moskovskaya str., 2

Review

For citations:

Svistun L.I., Bobylyov E.E., Nirov A.D., Storozhenko I.D., Popov R.A. Influence of Pre-Carburization on the Structure and Properties of Chromium Coatings on Steels Formed by Diffusion Alloying in Liquid Metal Media Solutions. Safety of Technogenic and Natural Systems. 2025;(2):170-178. https://doi.org/10.23947/2541-9129-2025-9-2-170-178. EDN: WDDMOV