Scroll to:

The Use of Coal Mine Methane as a Natural Gas Motor Fuel for Commercial Motor Transport in Donbass Cities

https://doi.org/10.23947/2541-9129-2025-9-3-208-220

EDN: HTLYBN

Abstract

Introduction. Coal mine methane, a greenhouse gas released during underground coal mining, is considered to be a cause of global climate change. However it is also a valuable energy resource. Currently, the global utilization rate of coal mine methane is low, and the amount of methane released into the atmosphere is increasing every year. To limit greenhouse gas emissions, several legislative initiatives have been implemented, including the Kyoto Protocol, the Paris Agreement, and Federal Law No. 296-FZ “On Limiting Greenhouse Gas Emissions”. In the conditions of Donbass, the task of mine methane utilization is relevant due to the dense location of emission sources and the need to improve the safety of mining operations, as well as to ensure the implementation of the principle of integrated field development. In addition, the ongoing hostilities have led to an increase in fuel prices in the region and an increase in road transport due to the limited availability of rail, sea, and air transportation. The aim of the research is to conduct a calculated assessment of the energy efficiency of using mine methane from Donbass coal deposits as motor fuel for commercial vehicles with internal combustion engines.

Materials and Methods. As an example, the studies were conducted on BAZ-2215 vehicles on the GAZelle Business chassis, GAZelle Next Citiline, and PAZ 3203, which were commonly used on urban routes in Makeyevka (DPR). These vehicles were equipped with UMZ, ZMZ, and Cummins spark and diesel engines. The full composition of methane-air mixture samples from several mines (Chaykino Mine, Makeyevka, Komsomolets Donbassa Mine, Kirovskoye), taken from degassing systems, was determined in the laboratories of Makeevka Research Institute for Mining Safety and Donetskavtogaz using a Kristallyuks 4000M gas chromatograph. The energy efficiency of engines operating on various types of fuel, including mine methane, as well as the performance characteristics of selected buses (fuel consumption, distance-to-empty, and carbon dioxide emissions) under urban driving cycles according to GOST R 54810–2011, were determined through a series of calculations using well-established methods.

Results. An estimation of the energy efficiency of mine methane as a gas engine fuel has been performed. In the range of concentrations of the studied samples of gas-air mixtures, the calculated maximum loss of effective power for ZMZ and UMZ spark engines was up to 15%. For gas-diesel engines, such as Cummins, power could be increased by up to 29%. These findings did not prevent selected buses from operating under driving cycles in accordance with GOST R 54810–2011. Under these conditions, fuel consumption and range per refueling depended significantly on the component composition of mine methane. For the samples studied, it was 1.8–3.5 times worse than for natural gas used for refueling. Emissions of carbon dioxide were reduced by 62–73% compared to gasoline.

Discussion. Due to the specific features of degassing processes and the mining and geological conditions of different mines, the alternative fuel discussed in this article has a variable component composition. In this regard, the transfer of PAZ and GAZ bus rolling stock to a byproduct of coal mining — mine methane — is associated with several challenges. These include the need for more powerful fuel systems (three times or more than the power supply systems of internal combustion engines of comparable power, operating on compressed gas) and deterioration in fuel-economic and traction-speed properties of vehicles, as well as reduced range. A quantitative assessment of these changes has been obtained through research. The positive impact of the proposed measures stems from the reduction in negative environmental impact by using mine methane as a fuel for vehicles, which reduces the carbon footprint of road transport and decreases the consumption of liquid hydrocarbon fuel.

Conclusion. As a result of the study, it has been found that the methane from the Donbass coal mines can be used as motor fuel for commercial vehicles such as city buses. The study has determined the corresponding energy efficiency parameters (the effective power generated by internal combustion engines, the specific fuel consumption, the range of vehicles under driving cycles, etc.), as well as the degree of their reduction compared to traditional fuels. It has been established that this does not affect the performance of transportation work (in compliance with GOST R 54810–2011) and is beneficial from the perspective of saving non-renewable resources and improving environmental safety in the region.

For citations:

Savenkov N.V., Golovatenko E.L. The Use of Coal Mine Methane as a Natural Gas Motor Fuel for Commercial Motor Transport in Donbass Cities. Safety of Technogenic and Natural Systems. 2025;9(3):208-220. https://doi.org/10.23947/2541-9129-2025-9-3-208-220. EDN: HTLYBN

Introduction. Coal mine methane is a valuable fuel and energy source that is produced during coal mining [1] and during coal seam degassing [2] processes. Its efficient utilization can reduce greenhouse gas emissions [3], increase the economic efficiency of coal mining, and provide additional energy sources for road transport [4]. In conditions of limited global oil reserves and growing energy costs, the use of coal mine methane as a motor fuel is a promising direction [5], which makes it possible to reduce our dependence on fossil fuels and the environmental impact [6]. Within the Russian Federation, the share of methane in greenhouse gas emissions ranks second after carbon dioxide and amounts to 14%, almost half of which is the contribution of coal mines (400 million tons of CO2 equivalent per year) [7]. An increase in coal mining leads to an increase in the formation of coal mine methane [8], which requires an intensification of degassing1.

In a number of countries, the share of degassed methane used in the energy sector reaches 50–80% [7]. However, in Russia, a significant amount of it (more than 1 billion m3 per year [7]) is released into the atmosphere [9].

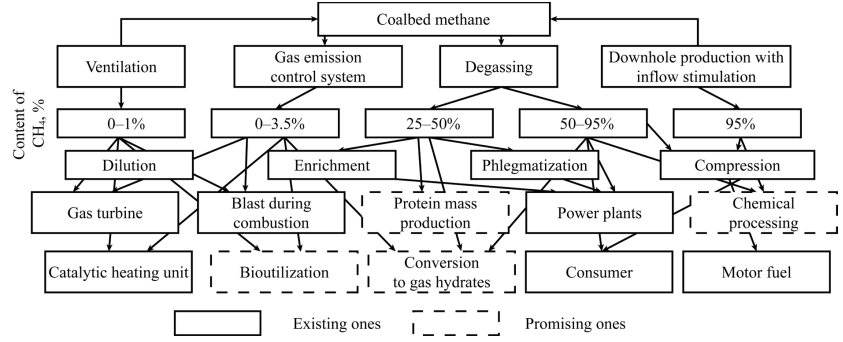

In world practice, coal mine methane is used in several ways, including combustion, cogeneration [10], chemical processing and injection into coal seams [11]. The choice of the most suitable technology depends on the component composition of the gas [12] and the characteristics of the deposit (Fig. 1) [13].

Fig. 1. The main uses of coal mine methane [13]

However, existing technologies only cover limited concentrations of methane [14] and, when used as a motor fuel, further research is needed on the effect of gas mixture composition on engine efficiency and car performance [5]. These factors create a need for a systematic analysis of the potential of coal mine methane as an alternative fuel and the development of methods for assessing its efficiency for commercial vehicles.

Existing studies mainly focus on stationary gas piston units [15] and a separate analysis relates to motor-car engines [16]. However, there is a key gap in the lack of data on the impact of variations in the composition of mine methane mixture on the energy performance of internal combustion engines in real-world driving cycles. Additionally, there is no assessment of the economic and environmental effectiveness of these solutions on a large regional scale. Therefore, a comprehensive theoretical justification for the use of coal mine methane in transportation is needed, as well as a method for calculating energy efficiency that considers the composition of gas, engine modes, and vehicle cycles.

The aim of the work is to conduct a calculated assessment of the energy efficiency of using coal mine methane from Donbass coal deposits as a motor fuel for automotive internal combustion engines of commercial vehicles. The tasks include: reviewing the features of coal mine methane degassing at domestic and foreign mines; analyzing its composition at coal companies in the Donbass region; modeling the operation of automotive internal combustion engines in various modes when using coal mine gas as fuel; quantifying energy efficiency (including performance and developed effective indicators) for mine gas-fueled motor transport power units compared to traditional fuels; identifying of conditions and limitations for safe and environmentally friendly operation of mine gas-fueled vehicles; and formulating recommendations on degassing and gas treatment technologies for widespread use in commercial transportation.

Materials and Methods. The work used laboratory methods for studying the composition of coal mine methane from the State Enterprise “Makeyevugol” “Chaikino Mine” (Makeyevka) and the State Unitary Enterprise of the DPR “Komsomolets Donbass Mine” (Kirovskoye). An integrated technological process was used to prepare laboratory gases. The degassing systems of these mines were equipped with two types of vacuum pumping stations — VN-50 water-ring vacuum pumps (manufactured in China), in which water was used as a working fluid; gas sampling was conducted in front of vacuum pumping stations; silica gel was used to remove moisture; rotary pumps with means of dedusting and removing moisture, gas sampling was conducted at the outlet into cylinders with a capacity of 2 liters. The processes of dilution of laboratory gas to the required concentration, as well as additional enrichment with natural gas, were not used. The full composition of the selected gas was determined in two laboratories: the gas analytical laboratory of the State Institution MAKNII (Makeevka Research Institute for Mining Safety) and the chemical laboratory of the State Enterprise Donbasstransgaz. A Crystallux 4000M gas chromatograph was used to analyze the composition of gases.

As an example, BAZ-2215 on the Gazelle Business chassis, Gazelle Next Citiline and PAZ 3203 were selected for research. These vehicles were common on urban routes in Makeyevka (DPR). According to the Municipal Unitary Enterprise “Dispatch Service” of the Makeyevka City Administration, 231 units of rolling stock of these brands were involved on 52 urban and 28 suburban routes of the city. Among them 122 units were of medium capacity (M3) and 109 units were of small capacity (M2). The prevailing number of buses was equipped with ZMZ, UMZ and Cummins engines. The main technical characteristics of the selected vehicles and their engines are shown in Table 1. The indicators of the engines selected as an example when running on coal mine methane of various compositions, as well as on traditional liquid fuels (developed effective power, effective specific and hourly fuel consumption, etc.), were determined based on the results of a series of thermal calculations performed using methodology [17].

The operational properties of motor vehicles (fuel consumption, range and carbon dioxide emissions), were measured under driving cycle (DC) conditions according to GOST R 54810–20112. These properties were obtained by numerical simulation of the movement process in accordance with methodology [18] when their engines were running on the fuels considered in the study.

Table 1

Characteristics of the vehicles in question and their internal combustion engines

|

Vehicle model |

GAZelle Next Citiline |

BAZ-2215 |

PAZ 3203 |

|

Category according to TR CU 018/2011 |

M2 |

M2 |

M3 |

|

Class according to GOST R 54810–20113 |

II |

II |

II |

|

Passenger capacity, person |

17 |

15 |

48 |

|

Gross weight, kg |

4950 |

3980 |

8500 |

|

Power-weight ratio, W/kg |

17.84 |

19.72 |

11.3 |

|

Engine type |

CUMMINS ISF2.8S4R129 |

EVOTECH А274 |

ZMZ-5234 |

|

Type |

Diesel, turbocharged and charge air cooler |

Petrol, 4-cycle, injected |

Petrol, 4-cycle, carburetor |

|

Number of cylinders and their arrangement |

4, in-line |

4, in-line |

8, V-engine |

|

Cylinder diameter and piston stroke, mm |

94×100 |

96.5×92 |

92х88 |

|

Cylinder capacity, l |

2.8 |

2.69 |

4.67 |

|

Compression ratio |

16.9 |

10 |

7.6 |

|

Rated power, net kW (hp) || at crankshaft speed, rpm |

88.3 (120) || 3,600 |

78.5 (106.8) || 4000 |

96 (130) 3200–3400 |

|

Maximum torque, net, Nm (kgfm) || at crankshaft speed, rpm |

295 (30.0) || 1,600–2,700 |

220.5 (22.5) || 2,350±150 |

314(32) || 2,250–2,500 |

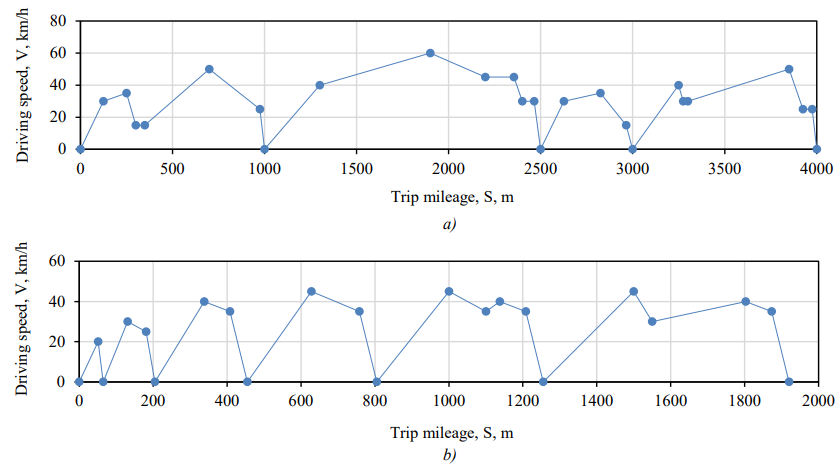

To do this, in the software environment of the Mathcad computer algebra system, the car power balance equation was solved at each DC point [18]. Figure 2 shows the selected DCs representing the dependence of speed of movement V on trip mileage S

Fig. 2. Driving cycles selected for the research: a — urban cycle on the road for Class II M2 vehicles; b — urban cycle on the road for Class II M3 vehicles

These cycle variants were characterized by minimal accelerations, which was due to the low energy consumption of cars (Table 1) and the expected loss of maximum power developed by their engines when running on coal mine methane.

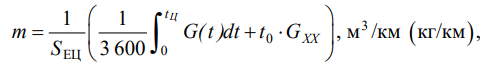

The travel fuel consumption was determined as follows:

(1)

(1)

where SЕЦ — DC distance (4 km for M2 category and 1.92 km for M3 category; tЦ — DC duration (497 s for M2 category and 288 s for M3 category, excluding stops; G(t) — function of hourly fuel consumption of travel time in a cycle, m3/h (kg/h); t0 — total duration of stops, s; GXX — часовой расход топлива двигателя в режиме hourly fuel consumption of the engine in the minimum stable idle rotation mode, m3/s (kg/s), GXX = 0.0007 m3/s for gas ICEs and GXX = 0.005 kg/s liquid-fueled ICEs [17]).

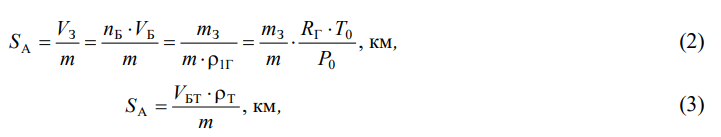

The bus range in DC conditions was calculated using formula (2) for gaseous fuels and formula (3) for liquid fuels:

where VЗ — gas volume under normal conditions (NC) in the car; nБ — number of cylinders in the car; VБ — maximum gas volume with which one cylinder can be filled under NC; mЗ — filling mass of gas; ρ1Г — gas density under NC;

RГ — gas constant (Table 2); T0 and P0 — temperature and atmospheric pressure under NC, respectively; VБТ — fuel tank volume; ρ1Г — liquid fuel density under NC.

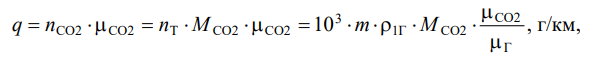

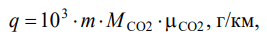

СО2 emissions under DC conditions were determined as follows:

– for gas-fueled internal combustion engines (including for gas-diesels):

(4)

(4)

where nCO2 — amount of substance (СО2) in the exhaust gases (EG), related to one kilometer, mol/km; μCO2 —CO2 molecular weight, g/mol; nТ — number of moles of fuel consumed per kilometer, mol/km; MCO2 — amount of СО2, generated during the combustion of gaseous fuel, mol/mol, (6); μГ — the molecular weight of the gas, g/mol (Table 2);

– for engines running on liquid fuel:

(5)

(5)

where MCO2 — amount of СО2, produced during the combustion of liquid fuel, kmol/kg, (7).

For gas diesel, MCO2 was determined by the formula:

where n, m, r — respectively, the number of carbon, hydrogen, and oxygen atoms in gas molecules of the gas mixture; CnHmOr — volume fraction of gas in the gas mixture, Table 2; C — mass fraction of carbon in the fuel (Table 2); gТ — mass of liquid fuel per 1 kmol of gas fuel, gТ = 0.0084 kg/kmol.

Results. We have obtained the following results:

- the component composition of laboratory gases selected from Donbass collieries has been determined (Table 2);

- for bus models commonly used on urban routes in Makeyevka, a thermal calculation of internal combustion engines has been performed when running on coal mine methane with different component compositions (Tables 3–5);

- numerical simulation of bus traffic has been carried out under urban DC conditions in accordance with GOST R 54810–20114, and efficiency indicators for the use of coal mine methane as motor fuel have been determined (Table 6).

In Tables 2–6, the following designations were used for laboratory gas samples: gas No. 1 — Chaykino mine; gas No. 2 — natural gas used for refueling cars (from a gas filling compressor station); gas No. 3 — reference gas mixture according to GOST 31371.3–2008; gas No. 4 — Komsomolets Donbassa Mine, first WPS station; gas No. 5 — Komsomolets Donbass mine, second WPS.

Table 2

Component composition of laboratory gases (fuels)

|

Fuel component composition |

Volume fractions |

Mass fractions |

|||||

|

Gas No. 1 |

Gas No. 2 |

Gas No. 3 |

Gas No. 4 |

Gas No. 5 |

Gasoline |

Diesel |

|

|

СО |

0 |

0 |

0 |

0 |

0 |

– |

– |

|

Н2 |

0 |

0 |

0 |

0 |

0.0000417 |

– |

– |

|

СН4 |

0.485 |

0.959 |

0.805 |

0.2745 |

0.445 |

– |

– |

|

С2Н6 |

0.00359 |

0.02253 |

0.04 |

0 |

0 |

– |

– |

|

С3Н8 |

0.00113 |

0.00694 |

0.005 |

0 |

0 |

– |

– |

|

С4Н10 |

0.005045 |

0.00201 |

0.005 |

0 |

0 |

– |

– |

|

C5H12 |

0.000058 |

0.00031 |

0 |

0 |

0 |

– |

– |

|

О2 |

0.0158 |

0.00008 |

0 |

0.1686 |

0.11683 |

– |

– |

|

СО2 |

0.00137 |

0.00204 |

0.09 |

0.003 |

0.002583 |

– |

– |

|

N2 |

0.4878 |

0.00696 |

0.06 |

0.5538 |

0.435417 |

– |

– |

|

С6Н14 |

0 |

0.00012 |

0 |

0 |

0 |

– |

– |

|

Не |

– |

– |

0 |

0.0001 |

0.000075 |

– |

– |

|

C |

– |

– |

– |

– |

– |

0.855 |

0.860 |

|

H |

– |

– |

– |

– |

– |

0.145 |

0.126 |

|

O |

– |

– |

– |

– |

– |

0 |

0.014 |

|

Results of thermal calculation according to method [17] |

|||||||

|

Specific gas constant, RГ, J/(kg·K) |

370.5 |

496 |

411 |

327 |

359 |

– |

|

|

Molecular weight, μГ, g/mol |

22.4 |

16.76 |

20.23 |

25.43 |

23.16 |

|

|

|

Lower heat of fuel combustion, gas (gasoline/diesel) MJ/m3, (MJ/kg) |

18.256 |

18.257 |

33.5 |

32.3 |

9.8 |

(43.9) |

(41.99) |

|

Theoretically required amount of combustion air, kmol/kg, (kg/kg) |

4.835 |

9.842 |

8.690 |

1.829 |

3.717 |

(14.95) |

(14.3) |

|

Heat of combustion of a combustible mixture, (gasoline/diesel) kJ/m3, (kJ/kg) |

70086 |

70087 |

75011 |

74722 |

77598 |

(83555) |

(52911) |

To assess the changes in the performance parameters (power output and fuel consumption) of selected models of internal combustion engines when running on coal mine methane compared to traditional liquid hydrocarbon and gas fuel, we performed a series of thermal calculations in accordance with methodology [17]. The results of these calculations are presented in Tables 3–5.

Table 3

Results of thermal calculation of the UMZ-A27460 EvoTech engine

|

Indicator/ parameter |

Units |

Gas No. 1 |

Gas No. 2 |

Gas No. 3 |

Gas No. 4 |

Gas No. 5 |

Gasoline |

|

Excess air coefficient |

– |

1 |

1 |

1 |

1 |

1 |

1 |

|

Residual gases temperature |

K |

918 |

945 |

938 |

956 |

946 |

954 |

|

Final compression pressure |

MPa |

1.787 |

1.787 |

1.787 |

1.787 |

1.787 |

1.787 |

|

Final combustion pressure |

MPa |

6.135 |

6.342 |

6.342 |

6.432 |

6.360 |

6.962 |

|

Final combustion temperature |

oC |

2197 |

2303 |

2278 |

2342 |

2303 |

2505 |

|

Indicated mean pressure |

MPa |

0.91 |

0.96 |

0.95 |

0.98 |

0.96 |

1.1 |

|

Indicated efficiency |

– |

0.36 |

0.35 |

0.35 |

0.35 |

0.35 |

0.34 |

|

Mechanical efficiency |

– |

0.811 |

0.821 |

0.818 |

0.824 |

0.820 |

0.834 |

|

Effective efficiency |

– |

0.296 |

0.294 |

0.293 |

0.293 |

0.294 |

0.287 |

|

Mean effective pressure |

MPa |

0.739 |

0.791 |

0.779 |

0.807 |

0.788 |

0.869 |

|

Net torque |

Nm |

158 |

169 |

167 |

172 |

169 |

186 |

|

Engine output (nominal) |

kW |

66.3 |

71 |

70 |

72.4 |

70.7 |

78.5 |

|

Hourly gas consumption, G, (gasoline) |

m3/h (kg/h) |

44.1 |

23.7 |

26.5 |

90.9 |

54.5 |

(22.2) |

Table 4

Results of thermal calculation of the ZMZ-5234 engine

|

Indicator/ parameter |

Units |

Gas No. 1 |

Gas No. 2 |

Gas No. 3 |

Gas No. 4 |

Gas No. 5 |

Gasoline |

|

Excess air coefficient |

– |

1 |

1 |

1 |

1 |

1 |

1 |

|

Residual gases temperature |

K |

896.6 |

923.4 |

915.6 |

932.9 |

923.4 |

932.3 |

|

Final compression pressure |

MPa |

1.420 |

1.420 |

1.420 |

1.420 |

1.420 |

1.420 |

|

Final combustion pressure |

MPa |

4.875 |

5.039 |

5.039 |

5.110 |

5.054 |

5.740 |

|

Final combustion temperature |

oC |

2183.6 |

2287.5 |

2263.2 |

2325.3 |

2288.3 |

2384.1 |

|

Indicated mean pressure |

MPa |

0.762 |

0.807 |

0.796 |

0.821 |

0.806 |

0.874 |

|

Indicated efficiency |

– |

0.322 |

0.317 |

0.316 |

0.314 |

0.316 |

0.305 |

|

Mechanical efficiency |

– |

0.807 |

0.818 |

0.816 |

0.821 |

0.817 |

0.832 |

|

Effective efficiency |

– |

0.261 |

0.259 |

0.258 |

0.258 |

0.258 |

0.253 |

|

Mean effective pressure |

MPa |

0.615 |

0.660 |

0.649 |

0.674 |

0.657 |

0.727 |

|

Net torque |

Nm |

229.1 |

245.7 |

241.6 |

250.9 |

244.6 |

270.7 |

|

Engine output (nominal) |

kW |

81.5 |

87.5 |

86.1 |

89.3 |

87.1 |

96.1 |

|

Hourly gas consumption, G, (gasoline) |

m3/h (kg/h) |

61.8 |

33.2 |

37.2 |

127.4 |

76.4 |

31.2 |

Table 5

Results of thermal calculation of the CUMMINS ISF2.8S4R129 engine

|

Indicator/ parameter |

Units |

Gas No. 1 |

Gas No. 2 |

Gas No. 3 |

Gas No. 4 |

Gas No. 5 |

Diesel |

|

Excess air coefficient for gas (for liquid fuel) |

– |

1.05 |

1.05 |

1.05 |

1.05 |

1.05 |

(1.6) |

|

Residual gases temperature |

K |

850.4 |

874.1 |

867.5 |

879.6 |

882.8 |

792.4 |

|

Final compression pressure |

MPa |

6.735 |

6.735 |

6.735 |

6.735 |

6.735 |

6.720 |

|

Final combustion pressure |

MPa |

12.123 |

12.123 |

12.123 |

12.123 |

12.123 |

12.096 |

|

Final combustion temperature |

oC |

2239.5 |

2323.2 |

2301.1 |

2342.5 |

2359.5 |

1956.7 |

|

Indicated mean pressure |

МПа |

1.453 |

1.531 |

1.516 |

1.545 |

1.587 |

1.292 |

|

Indicated efficiency |

– |

0.432 |

0.423 |

0.423 |

0.412 |

0.414 |

0.491 |

|

Mechanical efficiency |

– |

0.848 |

0.856 |

0.854 |

0.857 |

0.861 |

0.822 |

|

Effective efficiency |

– |

0.366 |

0.362 |

0.362 |

0.353 |

0.356 |

0.404 |

|

Mean effective pressure |

MPa |

1.232 |

1.310 |

1.295 |

1.324 |

1.367 |

1.062 |

|

Net torque |

Nm |

272.3 |

289.4 |

285.9 |

292.5 |

301.8 |

234.6 |

|

Engine output |

kW |

102.7 |

109.1 |

107.8 |

110.3 |

113.8 |

88.4 |

|

Hourly gas consumption, G, (diesel) |

m3/h (kg/h) |

55.2 |

29.6 |

33.2 |

114.7 |

72.2 |

(18.8) |

From the data given in Tables 3–4, it follows that for the spark ignition gas engines considered in the study:

- the maximum rated power developed when using gas No. 4 as a fuel, and amounted, respectively, to 72.4 kW for the UMZ–A27460 EvoTech with an hourly fuel consumption of 90.9 m3/h and 89.3 kW for the ZMZ–5234 with a consumption of 127.4 m3/h;

- the minimum gas consumption was when using gas No. 2: 23.7 m3/h for the UMZ–A27460 EvoTech and 33.2 m3/h for the ZMZ–5234; however, the rated power of the UMZ engine would be reduced to 71 kW, which was almost 8 kW less than its rated power on gasoline (78.5 kW), and the ZMZ engine is up to 87.5 kW at 96 kW on gasoline.

According to Table 5, the maximum effective power of a CUMMINS ISF2.8S4R129 turbocharged diesel engine converted to gas-diesel was 113.8 kW at nominal power and grew on gas sample No. 5, which exceeded by 28.7% the corresponding figure for diesel fuel, while the hourly consumption was 72.2 m3/h.

The traction and speed properties of cars depended on the values of the maximum engine power output.

The calculations performed allowed us to determine, using dependencies (1)–(8), to determine the operational properties of buses under DC conditions when their engines were running on the fuels under consideration. The results are summarized in Table 6.

Table 6

The results of numerical simulations of the bus movement process in urban driving cycles in accordance with GOST R 54810–20115

|

Vehicle and operating conditions |

Performance characteristics |

Fuel |

|||||

|

Gas No. 1 |

Gas No. 2 |

Gas No. 3 |

Gas No. 4 |

Gas No. 5 |

LF1 |

||

|

BAZ–2215 on Gazelle Business chassis with UMZ–A27460 EvoTech engine; urban driving cycle for M2 category vehicles according to GOST R 54810–2011 (Fig. 2 а) |

Travel fuel consumption, m, m3/km (кг/км) |

0.232 |

0.128 |

0.142 |

0.43 |

0.27 |

(0.11) |

|

Fuel distance under DC conditions, SA, km |

172.4 |

312.5 |

281.7 |

93 |

148.1 |

438.3 |

|

|

СO2 emissions with EG, q, g/km |

213.2 |

235.8 |

254.7 |

211.9 |

214.6 |

343.3 |

|

|

Gazelle Next Citiline with CUMMINS ISF2,8S4R129 engine; urban driving cycle for M2 category vehicles according to GOST R 54810–2011 (Fig. 2 а) |

Travel fuel consumption, m, m3/km (kg/km) |

0.251 |

0.14 |

0.156 |

0.486 |

0.309 |

(0.099) |

|

Fuel distance under DC conditions, SA,km |

159.4 |

285.7 |

256.4 |

82.3 |

129.4 |

553.9 |

|

|

СO2 emissions with EG, q, g/km |

230.9 |

258 |

280 |

240 |

245.9 |

313.4 |

|

|

PAZ 3203 with ZMZ–5234 engine; urban driving cycle for M3 category vehicles according to GOST R 54810–2011 (Fig. 2 b) |

Travel fuel consumption, m, m3/km (kg/km) |

0.544 |

0.291 |

0.326 |

0.994 |

0.624 |

(0.256) |

|

Fuel distance under DC conditions, SA, km |

110.3 |

206.2 |

184.01 |

60.4 |

96.2 |

278.3 |

|

|

СO2 emissions with EG, q, g/km |

499.9 |

536 |

584.7 |

489.9 |

496 |

802.5 |

|

|

1 Liquid fuel (gasoline for UMZ–A27460 EvoTech, ZMZ–5234 internal combustion engines and diesel fuel for CUMMINS ISF2,8S4R129 internal combustion engines) |

|||||||

The minimum travel fuel consumption m (1) under different DC conditions was achieved on gas sample No. 2, and the maximum on sample No. 4. For BAZ–2215, the corresponding variation range was 3.36 at the lowest value of 0.128 m3/km, for the GAZELLE Next “Citiline” it was 3.47 at 0.14 m3/km, and for the PAZ 3203 — 3.42 at 0.291 m3/km.

Fuel distance SA (2) was inversely proportional to travel fuel consumption m and was equal to the fuel distance on gasoline: 21–71% for BAZ–2215, 15–91% for Gazelle Next Citiline and 22–74% for PAZ 3203. When calculating the fuel distance of gas-fueled vehicles of the M2 category, the number of cylinders of the KPG-1 class with a volume of VБ=0.05 м3 and a maximum allowable internal pressure of 200 bar was assumed to be nБ=4, and for the M3 category nБ=6. The fuel tank capacity for the M2 category was VБТ = 0.064 m3, and for M3 VBT = VБТ = 0.095m3.

Carbon dioxide emissions from gas-fueled buses significantly decreased in relation to liquid fuels: from 211.9 g/km for sample No. 4 to 254.7 g/km for BAZ-2215, which was 62% and 74% of the specific CO2 emissions from gasoline; from 230.9 g/km for sample No. 1 to 280 g/km for Gazelle Next Citiline, which was 74% and 89% of the specific emissions when driving on diesel fuel, and from 496 g/km for sample No. 5 to 584.7 g/km for PAZ 3203, which was 62%–73% of gasoline emissions.

Discussion. The data obtained from laboratory studies on selected samples of mine methane (see Table 2) confirmed the variability in its component composition. Specifically, the volume fraction of CH₄ ranged from 0.275 at the Komsomolets Donbassa Mine to 0.485 at the Chaykino Mine, corresponding to 27% and 50% of natural gas used for car fuel, respectively, as well as 34% and 60% of the reference gas mixture according to GOST 31371.3–20086. The impurity content of methane was up to 0.0098 in the sample from the Chaykino Mine. A significant portion of the gas sampled from the Komsomolets Donbassa Mine was air — 55% in volume for WPS No. 2 and 77% for WPS

No. 1 — making these sources less preferable for the selection of gas engine fuel.

As a result of the analysis of the data obtained during the calculations and presented in Tables 3–5, we found that the maximum estimated power loss for internal combustion engines during their operation on the considered fuel samples for UMZ–A274–60 EvoTech and ZMZ–5234 spark engines was 15%. At the same time, for the CUMMINS ISF2.8S4R129 diesel engine converted to gas diesel, this indicator could be increased significantly due to a decrease in the excess air coefficient (Table 5) and the presence of pressure charging. However, without further studies on the detonation stability of this engine and the strength of its crank mechanism, gas supply should be limited.

It was established that the considered gas-fueled vehicles, when operated on all selected samples of coal mine methane, had sufficient traction and speed characteristics to be able to operate under the specified DC conditions according to GOST R 54810-20117. Additionally, the use of mine methane as fuel not only reduces the release of these harmful gases into the atmosphere, thereby minimizing their contribution to the greenhouse effect, but it also reduces CO2 emissions from road transportation, thereby reducing the carbon footprint of vehicles.

A common challenge when using coal mine methane as a fuel is the variability in its composition and the presence of additional impurities in the form of air and inert gases, which can make up a significant volume fraction. Such motor fuel without prior enrichment with natural gas leads to the need to equip the internal combustion engine with power systems that will have increased capacity (almost three times) and feedback on the excess air coefficient in order to maintain the stoichiometric ratio of the fuel-air mixture. It is expected that the cost of such equipment will exceed the cost of a traditional automotive CNG storage and supply system by 50%. The power reserve values shown in Table 6 can be increased in proportion to the number of additional cylinders installed on the vehicle. However, with a mass of ≈ 65 kg in the refueled state (for example, CNG–1), the load capacity (and passenger capacity) of the car is also reduced. Accordingly, the results obtained in the work (Tables 3–6) made it possible to evaluate the fundamental possibility and energy efficiency of using coal mine methane as a gas engine fuel for commercial motor transport in the cities of Donbass. The economic feasibility of this is determined by a set of factors: the cost of degassing, the total cost of retrofitting cars, as well as the strategies adopted by enterprises for the implementation of the transport process.

Conclusion. Thus, as a result of a theoretical analysis performed on the basis of laboratory research data, it was found that coal mine methane from Donbass coal deposits could be used as a gas engine fuel to power internal combustion engines of UMZ–A274–60 EvoTech, ZMZ–5234, CUMMINS ISF2.8S4R129 models used on commercial vehicles of BAZ–2215, PAZ 3203 and Gazelle Next Citiline models. The decrease in maximum effective power that occurred did not interfere with the movement of cars under urban DC conditions according to GOST R 54810-20118. However, it required equipping with an upgraded fuel-air mixture preparation system.

This work is a part of the scientific research conducted by the authors. In the future, we plan to explore the following areas:

- Clarifying the effective performance of motor internal combustion engines when running on coal mine methane. For this purpose, motor tests are planned in the laboratory of the specialized scientific and technical center “Mechanization of Transport, Construction and Communal Works” of the Donbas National Academy of Civil Engineering and Architecture on the modernized stand KI–5543 of the GOSNITI. The tests will be carried out in both steady-state and non-steady-state modes using the device developed by the authors for sampling exhaust gases (RF patent RU 227257 U1)

- Development of mathematical models of the speed characteristics of internal combustion engines and their environmental indicators for the subsequent assessment of the operational properties of vehicles.

- Conducting a comprehensive assessment of the economic efficiency of converting commercial motor transport in Donbass to gas motor fuel.

- Determination of the amount of prevented environmental damage.

1. Global Methane Tracker. URL: https://iea.blob.core.windows.net/assets/b5f6bb13-76ce-48ea-8fdb-3d4f8b58c838/GlobalMethaneTracker_documentation.pdf (accessed 27.05.2025).

2. GOST R 54810–2011. Motor Vehicles. Fuel Economy. Test Methods. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200093157 (accessed: 21.05.2025).

3. Ibid.

4. GOST R 54810 2011. Motor Vehicles. Fuel Economy. Test Methods. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200093157 (accessed: 21.05.2025).

5. GOST R 54810 2011. Motor Vehicles. Fuel Economy. Test Methods. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200093157 (accessed: 21.05.2025).

6. GOST 31371.3–2008. Natural Gas. Determination of Composition with Defined Uncertainty by Gas Chromatography Method. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200068109 (accessed: 21.05.2025).

7. GOST R 54810–2011. Motor Vehicles. Fuel Economy. Test Methods. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200093157 (accessed: 21.05.2025).

8. GOST R 54810 2011. Motor Vehicles. Fuel Economy. Test Methods. Electronic Fund of Legal and Regulatory and Technical Documents. (In Russ.) URL: https://docs.cntd.ru/document/1200093157 (accessed: 21.05.2025).

References

1. Qingdong Qu, Hua Guo, Rao Balusu, Methane Emissions and Dynamics from Adjacent Coal Seams in a High Permeability Multi-Seam Mining Environment. International Journal of Coal Geology. 2022;253:103969. https://doi.org/10.1016/j.coal.2022.103969

2. Songling Jin, Wei Gao, Zichao Huang, Mingshu Bi, Haipeng Jiang, Rongjun Si, et al. Suppression Characteristics of Methane/Coal Dust Explosions by Active Explosion Suppression System in the Large Mining Tunnel. Fire Safety Journal. 2024;150(A):104251. https://doi.org/10.1016/j.firesaf.2024.104251

3. Pengfei Ji, Haifei Lin, Shugang Li, Xiangguo Kong, Xu Wang, Jingfei Zhang, et al. Technical System and Prospects for Precise Methane Extraction in the Entire Life Cycle of Coal Mining under the Goal of “Carbon Peak and Carbon Neutrality”. Geoenergy Science and Engineering. 2024;238:212855. https://doi.org/10.1016/j.geoen.2024.212855

4. Kuznetsov AN, Kolyada DA. The Use of Gas Fuel for Cars. In: Proceedings of the International Scientific and Practical Conference of Young Scientists and Specialists Dedicated to the 110th Anniversary of Voronezh State Agrarian University Named after Emperor Peter I “Innovative Technologies and Technical Means for Agriculture”, Voronezh, November 10–11, 2022. Voronezh: Voronezh State Agrarian University named after Emperor Peter the Great; 2022. P. 265–269. (In Russ.)

5. Ander Ruiz Zardoya, Inaki Lorono Lucena, Inigo Oregui Bengoetxea, Jose A Orosa, Research on the New Combustion Chamber Design to Operate with Low Methane Number Fuels in an Internal Combustion Engine with Pre-Chamber. Energy. 2023;275:127458. https://doi.org/10.1016/j.energy.2023.127458

6. Slavina YuA, Vozov DA. Application of Natural Gas as Fuel in Road Transport. In: Proceedings of the XIV International Scientific and Technical Conference “Topical Issues of Organization of Road Transportation, Traffic Safety and Operation of Vehicles” Saratov, April 18, 2019. Saratov: Saratov State Technical University named after Yuri Gagarin; 2019. P. 359–363. (In Russ.)

7. Pazyuchenko MA. Economic and Environmental Efficiency of Methane Extraction from Coal Seams. Ekonomicheskie Sistemy. 2023;16(2):173–181. (In Russ.) https://doi.org/10.29030/2309-2076-2023-16-2-173-181

8. Vigil DA, Johnson JrRL, Tauchnitz J. Improved Estimation Methods for Surface Coal Mine Methane Emissions for Reporting, Beneficial Use, and Emission Reduction Purposes and Relative to Australia's Safeguard Mechanisms. Journal of Environmental Management. 2025;376:124366. https://doi.org/10.1016/j.jenvman.2025.124366

9. Brodny J, Felka D, Tutak M. The Use of the Neuro–Fuzzy Model to Predict the Methane Hazard during the Underground Coal Mining Production Process. Journal of Cleaner Production. 2022;368:133258. https://doi.org/10.1016/j.jclepro.2022.133258

10. Shilov AA, Khramtsova AM. Utilization and Use of Mine Methane for Heat and Electricity Generation. Mining Informational and Analytical Bulletin. 2008;(S4):85–89. (In Russ.)

11. Nagaytsev I, Petrova Т. Comparative Analysis of Promising Abatement Technologies Greenhouse Gas Emissions from Coal Mines. Energy Policy. 2024;(1(192)):38–57. (In Russ.) URL: https://energypolicy.ru/wp-content/uploads/2024/02/ep-%E2%84%961192-1.pdf (accessed: 27.06.2025).

12. Tailakov OV, Zastrelov DN, Utkaev EA, Sokolov SV, Kormin AN, Smyslov AI. Prospects of the Coal Mine Methane Utilization. Bulletin of the Kuzbass State Technical University. 2015;(6(112)):62–67. (In Russ.) URL: https://vestnik.kuzstu.ru/index.php?page=article&id=2977 (accessed: 27.06.2025).

13. Konstantinova MS. Ways of Extraction and Industrial Use of Coal Mine Methane for Energy Purposes. Vestnik Sovremennykh Issledovanii. 2019;(1.8(28)):95–99. (In Russ.)

14. Durnin MK. The Choice of Effective Technologies for the Utilization of Coal Mine Methane to Improve the Industrial Safety of Coal Mines. Mining Informational and Analytical Bulletin. 2007;(S13):415–429. (In Russ.)

15. Beloshitskii MV, Troitskii AA. The Use of Coal Mine Methane as an Energy Carrier. Turbines & Diesels. 2006;(6):2–9. (In Russ.) URL: http://www.turbine-diesel.ru/rus/node/2108 (accessed: 27.06.2025).

16. Strokov AP, Levterov AM, Nechvolod PYu. Recycling of Mine Methane in Ecological Cogeneration Plant with Piston ICE. Bulletin of Kharkov National Automobile and Highway University. 2010;(48):89–93. (In Russ.)

17. Kuleshov AA. Development of Calculation Methods and Optimization of Internal Combustion Engine Work Processes. Dr. Sci. (Eng.) diss. Moscow; 2012. 235 p. (In Russ.)

18. Gorozhankin SA, Bumaga AD, Savenkov NV. Improving Car Fuel Efficiency by Optimising Transmission Parameters. International Journal of Automotive and Mechanical Engineering. 2019;16(3):7019–7033. https://doi.org/10.15282/ijame.16.3.2019.14.0526

About the Authors

N. V. SavenkovRussian Federation

Nikita V. Savenkov - Cand. Sci. (Eng.), Associate Professor, Head of the Department of Automobile Transport, Service and Operation, Donbass National Academy of Civil Engineering and Architecture.

2, Derzhavina St., Makeyevka, Donetsk People's Republic, 286128

Scopus ID 57218608498; ResearcherID U-8627-2017

E. L. Golovatenko

Russian Federation

Ekaterina L. Golovatenko - Senior Lecturer of the Technosphere Safety Department, Donbass National Academy of Civil Engineering and Architecture.

2, Derzhavina St., Makeyevka, Donetsk People's Republic, 286128

Review

For citations:

Savenkov N.V., Golovatenko E.L. The Use of Coal Mine Methane as a Natural Gas Motor Fuel for Commercial Motor Transport in Donbass Cities. Safety of Technogenic and Natural Systems. 2025;9(3):208-220. https://doi.org/10.23947/2541-9129-2025-9-3-208-220. EDN: HTLYBN