Scroll to:

Study of the Processes of Electric Heating Using High-Frequency Currents in a Magnetic Field

https://doi.org/10.23947/2541-9129-2025-9-4-331-340

EDN: PLICAE

Abstract

Introduction. When heating with high-frequency currents (HFCs) at high speeds, more significant strengthening effects can be observed compared to using machine generators. Therefore, hardening at high frequencies is more efficient. However, the increase in the generator frequency results in a decrease in the depth of penetration of eddy currents and an increased unevenness of heating across the cross-section. The application of a constant external magnetic field during HFC hardening can increase the depth of eddy current penetration and create more uniform heating. Unfortunately, there is not enough information available on the effect of the external magnetic field on HFC heating processes and phase transformations in steel. Currently, there are no quantitative estimates for the impact of an external magnetic field on changes in the kinetics of electric heating and the penetration depth of eddy currents. In connection with the above, the aim of this paper is to investigate changes in the kinetics of high-frequency heating of iron-carbon alloys when an external constant magnetic field is applied and, and, based on this, to consider the potential for technological applications.

Materials and Methods. Theoretical assessment of the influence of an external magnetic field on the change in the kinetics of electric heating and the penetration depth of eddy currents is based on the general theory of induction heating kinetics. An experimental study of the influence of a magnetic field on the kinetics of high-frequency current heating was performed on samples of 45 steel, pearlitic gray (SCh30), and ferritic malleable cast iron (KCh30-6). The temperature distribution over the cross-section of ferromagnetic materials during induction heating with an external magnetic field has been studied using special samples of iron, 45 steel, and SCh30 gray pearlitic cast iron. Electric tempering processes have been investigated on samples of U8A steel using a vacuum tube generator (heating temperature — 450℃, heating rate — 750℃/s). Changes in austenite grain size after high-speed heating with external magnetization have been examined on samples of reduced-hardenability 55PP steel. To study the processes of thermal treatment in a magnetic field during experiments involving heating samples using high-frequency currents, a specially designed electromagnet was created to apply an external constant magnetic field.

Results. Theoretical curves were constructed for heating conditions with and without an external constant magnetic field. Experimental data on the effect of an external constant magnetic field on induction heating in the surface layer of various materials were summarized in kinetic diagrams. Evidence that the observed changes were due to increased depth of penetration of eddy currents came from experiments on cylindrical samples of 45 steel with different wall thicknesses. Kinetic curves were provided for estimating the temperature field (at 6 points at different depths) during high-frequency current heating with and without external magnetization. The paper presents experimental data on the micro-hardness distribution across the cross-section of a U8 steel sample after quenching, quenching and electric tempering, quenching and electric tempering with external magnetization, and quenching and bulk tempering. It also includes the results of the study of the austenite grain size of 55PP steel after high-speed heating with external magnetization and conventional (slow) deep heating.

Discussion. The application of a high-intensity external constant magnetic field during the first quasi-stationary process resulted in a decrease in the rate of induction heating of the ferromagnetic material and an increase in the depth of its uniform heating. However, above the Curie point, the effect of the magnetic field was negligible due to the low magnetic susceptibility of the material, and the heating rate remained unchanged as if there was no field present. In addition, due to the insignificant difference in the values of magnetic permeability below and above the Curie point during heating in the field, the thermal curve did not exhibit the characteristic inflection typical of kinetic curves observed during the transition of the surface layer to a paramagnetic state. Experiments with electric tempering have demonstrated that by applying an external field, it was possible to temper a material to the desired depth and it could be done on a single high-frequency current setup. The size of the austenite grains after high-speed heating with magnetization was reduced compared to conventional deep heating of steel with low hardenability, eliminating the issue of induction heating for low-hardenability steel.

Conclusion. The results of the study demonstrated that the use of an external magnetic field enabled the achievement of strengthening effects during heating at higher frequencies, thereby eliminating the drawbacks of such heating methods.

Keywords

For citations:

Pustovoit V.N., Dolgachev Yu.V., Pivchenkov A.S. Study of the Processes of Electric Heating Using High-Frequency Currents in a Magnetic Field. Safety of Technogenic and Natural Systems. 2025;9(4):331-340. https://doi.org/10.23947/2541-9129-2025-9-4-331-340. EDN: PLICAE

Introduction. The basic principles of the heat treatment technology of steel in a magnetic field (HTMF) are described in the monograph [1]. This technology allows obtaining structural states and properties that are not achievable under normal conditions. One of the advantages of HTMF is its efficiency in the piecewise processing of products [2], for example, by using high-frequency currents (HFCs) as a heating source [3].

Due to the fact that more noticeable hardening effects can be observed when heating with HFCs at high speeds compared to using machine generators, it would be beneficial to harden at higher frequencies. However, the increase in the frequency of the generator results in a decrease in the depth of penetration of eddy currents and an increase in unevenness of heating across the cross-section. The theoretical and practical aspects of HFC heating of metal products have been well presented in [4][5]. Meanwhile, there is a lack of information about changes that occur during high-speed induction heating with an external permanent magnetic field, especially in the context of ongoing phase transformations in steels.

Qualitative data have been experimentally obtained [4] that the application of a constant external magnetic field during HFC quenching can lead to an increase in the penetration depth of eddy currents, which, in turn, increases the uniformity of heating at the stage of the first quasi-stationary electric heating process [6]. From a technological point of view, the most appropriate application of this phenomenon is for high-speed electric tempering [7][8], since there is a problem of insufficient HFC heating depth of the ferromagnetic hardened layer, which makes it necessary to use another generator operating at a lower frequency for heating for tempering. Currently, there are no quantitative estimates of the effect of an external magnetic field on changes in the kinetics of electric heating and the depth of penetration of eddy currents.

In connection with the above, the authors of this research aim to study changes in the kinetics of HFC heating of iron-carbon alloys under the influence of an external permanent magnetic field, and based on the results obtained, consider the possibilities for their technological application.

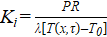

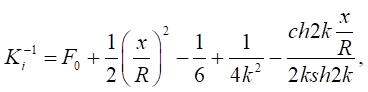

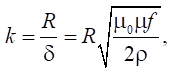

Materials and Methods. Theoretical assessment of the influence of an external magnetic field on changes in the kinetics of electric heating and the depth of penetration of eddy currents was based on the general theory of induction heating kinetics [9][10]. The equation of thermal conductivity in the case of heating steel to the temperature of magnetic transformations in the surface layer was used with the introduction of dimensionless quantities of time (Fourier criterion  ), temperature (Kirpichev criterion

), temperature (Kirpichev criterion  ), without taking into account the transient process of power redistribution (P) and had the form:

), without taking into account the transient process of power redistribution (P) and had the form:

(1)

(1)

where R — cylindrical sample radius.

where δ — eddy currents penetration depth; μ — relative magnetic permeability of the material; μ0 — magnetic permeability of air; f — current frequency; ρ — electrical resistivity of the material; λ — thermal conductivity coefficient; α — temperature conductivity coefficient; T(x, τ) — temperature as a function of time (τ) and distance from surface (x); T0 — initial temperature.

The experimental study of the effect of the magnetic field on the kinetics of HFC heating was conducted on samples of 45 steel, pearlitic gray (SCh30) and ferritic ductile iron (KCh30-6). Thermocouple readings from the surface layer were recorded using an analog-to-digital converter (ADC) L-CARD E14—440 (bit depth – 14 bits, conversion frequency — up to 400 kHz). Solid cylindrical samples of Æ 0.8 mm made of various materials were used, as well as hollow samples of 45 steel with wall thicknesses of 1 and 2 mm.

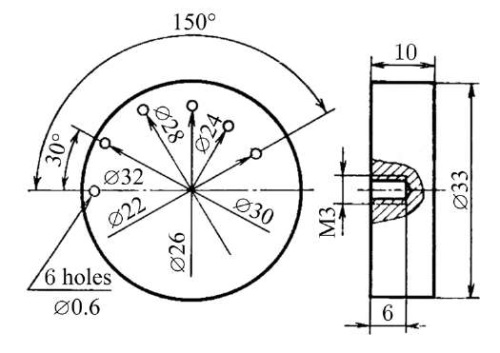

The temperature distribution over the cross-section of a ferromagnetic material during induction heating in an external magnetic field was studied on special samples (Fig. 1) made of technical iron, 45 steel and gray pearlitic cast iron SCh30. As can be seen in Figure 1, temperature control was carried out on a sample at six points located at distances from the edge of 1, 3, 5, 7, 9, and 11 mm. In each of the Æ 0.6 mm holes, a Æ 0.2 mm chromel-alumel thermocouple was installed, connected to one of the 16 differential ADC L-CARD E14–440 input channels, which transmitted data to a PC with simultaneous recording of all channels in the LGraph2 software.

Fig. 1. Design of samples for temperature field assessment

The study of electric tempering processes was conducted on U8A steel samples using a lamp generator. Electric tempering was performed at 450°C, the heating rate was 750°C/s. The usual oven tempering process lasted for one hour. Microhardness was measured on a PMT-3 device at a load of 100 g.

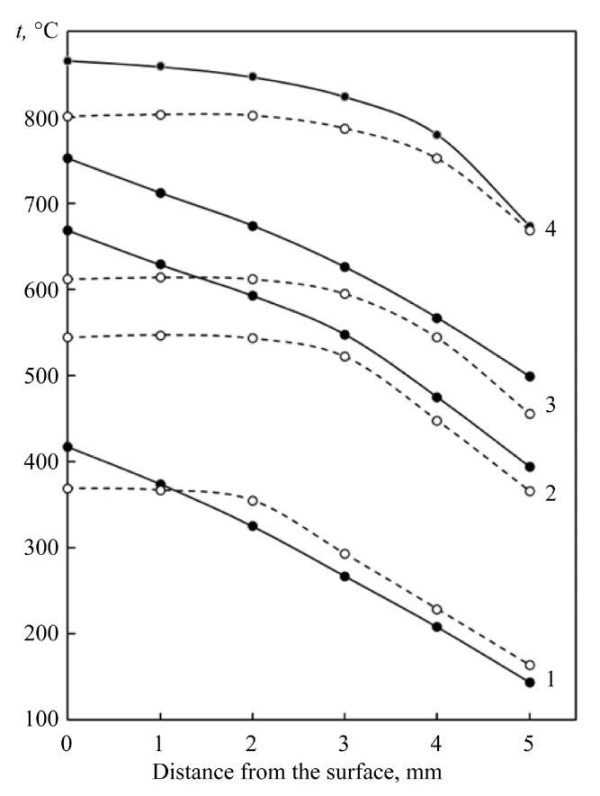

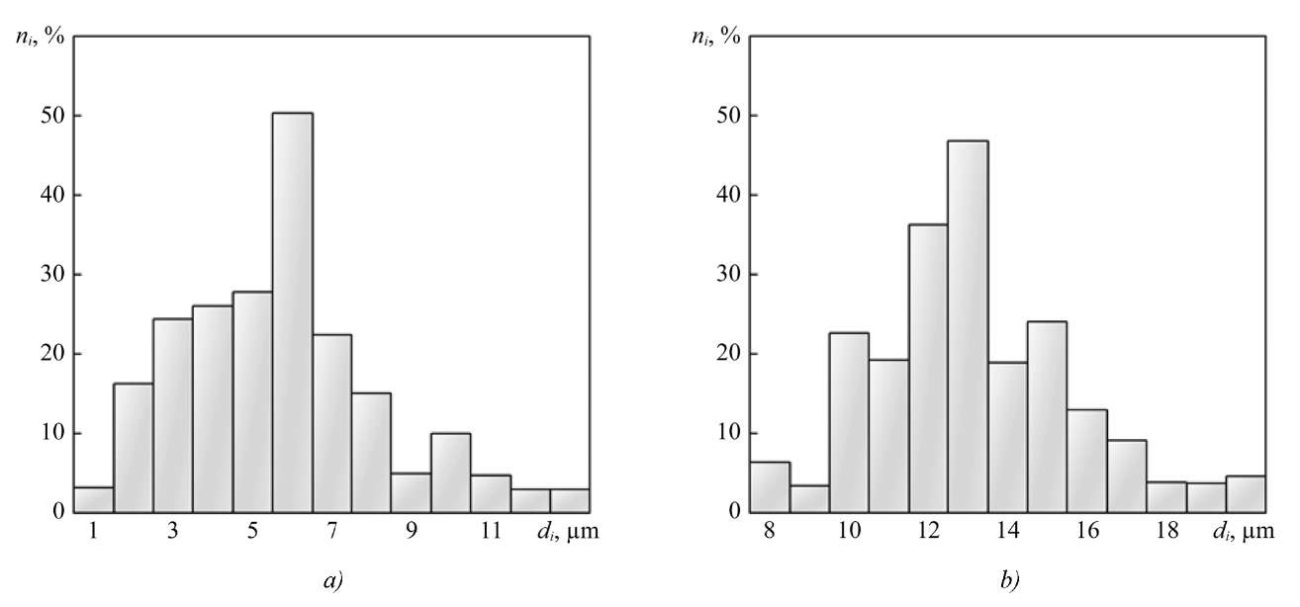

Changes in the austenitic grain score after high-speed heating with external magnetization were studied on 55PP steel samples of Æ 18 mm. Heating was carried out to a temperature of 950°C using machine (heating rate in the field of phase transformations — 8°C/s) and lamp (90°C/s) generators. The boundaries of the austenitic grain were studied by chemical etching in a one percent picric acid solution heated to 60°C with the addition of detergent. Histograms were constructed based on the measurement results of the largest grains dj visible in the plane of the slot in 20 fields of view at magnification × 1000. The average true grain diameters were calculated using the formula:

(2)

(2)

where nj — number of measured sections in the jth dimension group; k — number of groups.

The task of studying the processes of high-speed HTMF in relation to high-speed HFC heating had a number of technical difficulties associated with the imposition of an external permanent magnetic field around the inductor, and therefore a special electromagnet was designed with a number of features. The axes of the cores were as close as possible to the panel of the high-frequency generator, which determined the use of a core and coils of rectangular cross-section. The magnetic circuit of the electromagnet had a double reverse yoke. Water-cooled conical pole tips were used. The core cross-section relative to the yoke was increased by 130%, which reduced its magnetic resistance and minimized the dissipative flow. The conical shape of the tips made it possible to increase the field strength in the working air gap of 50 mm to 600 kA/m.

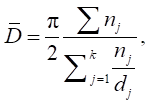

Results. Based on equation (1), theoretical curves were constructed for heating conditions without a field and with an external permanent magnetic field (Fig. 2). The calculation was performed for a cylindrical sample with a diameter of 8 mm made of steel with a ferritic structure: ρ = 36 ⋅ 10⁻⁸ Ohm⋅m; μ = 1000 — at a temperature of 20°C; μ = 1 — above the Curie point; μ = 7 at a temperature of 20°C in a magnetic field with a strength of 160 kA/m (taking into account the external demagnetizing factor of the sample); f = 440 kHz; assuming that the Curie point corresponded to dimensionless temperature Ki = 1.13. From the appearance of the curves, it was possible to judge about the greater uniformity of the heating process in the presence of external magnetization.

Fig. 2. Theoretical curves of high-speed heating without an external magnetic field (solid line) and with it (dashed line)

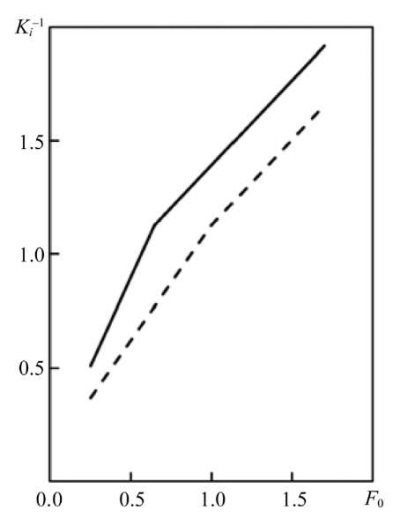

Experimental data on the effect of an external permanent magnetic field on induction heating in the surface layer of various materials were summarized in kinetic diagrams and shown in Figure 3.

Fig. 3. Thermal curves of induction heating without a magnetic field (solid line) and with a magnetic field (dashed line) on samples made of:

a, b — 45 steel; c — KCh30-6; d — SCh30

The proof that the observed changes were associated precisely with an increase in the penetration depth of eddy currents was experimental data obtained on cylindrical samples made of 45 steel having different wall thicknesses (1 and 2 mm and a solid cylinder Æ 8 mm). Figure 4 provides their heating curves.

Fig. 4. Thermal curves of samples without an external field (solid line) and in a magnetic field (dashed line) with a wall thickness of:

а — 1 mm; b — 2 mm; с — solid cylinder of Æ 8 mm

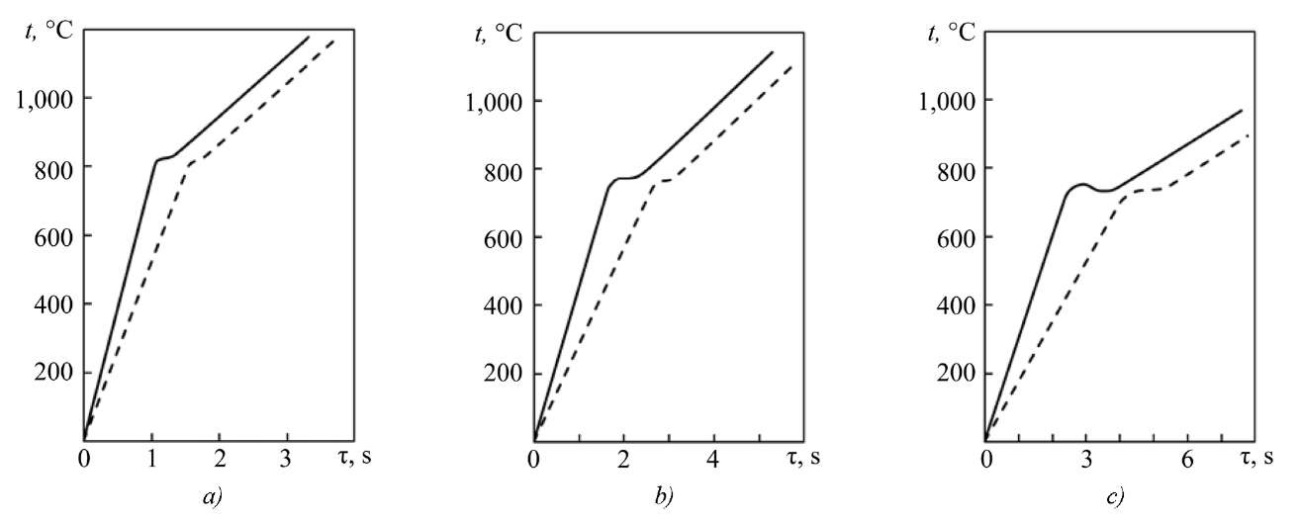

The temperature field assessment results (at six points at different depths) during HFC heating with and without external magnetization are shown in Figures 5 and 6. Figure 5 shows kinetic curves for perlite gray cast iron SCh30, and Figure 6 — for 45 steel.

Fig. 5. Heating curves of SCh30 (a — without a field; b — in a magnetic field) at a distance from the surface:

1 — 1 mm; 2 — 3 mm; 3 — 5 mm; 4 — 7 mm; 5 — 9 mm; and 6 — 11 mm

When heated in a magnetic field, the penetration depth of eddy currents did not depend on the structure of the material and turned out to be ~10 (for pearlite) and 17 (for ferritic) times more than when heated without a field. This indicated the possibility to implement in practice the quenching mode with electric tempering when heated from a single generator, since without magnetization it was impossible to warm up the entire hardened zone. Figure 7 shows experimental data showing the distribution of microhardness over the cross section of a U8 steel sample after quenching, quenching and electric tempering, quenching and electric tempering with external magnetization, quenching and volumetric tempering.

Fig. 6. Temperature distribution at different distances from the surface under normal heating (solid line) and with external magnetization (dashed line) at time points

1 — 3 s; 2 — 6 s; 3 — 7 s; 4 — 11.5 s

Fig. 7. Microhardness distribution over the cross section after:

1 — HFC quenching; 2 — HFC quenching and electric tempering without magnetization; 3 — HFC quenching and electric tempering with magnetization; 4 — HFC quenching and volumetric tempering in the furnace

Carbon steels with reduced through-hardening capability can be subjected to HFC surface quenching [11][12], but they have low heating rate in the region of phase transformations, which leads to a large austenite grain size (and, consequently, reduced mechanical properties in the surface layer). It turns out that the characteristic features of the fine structure of austenite, which are caused by induction heating, are offset by grain growth — high structural strength is lost. Figure 8 shows the results of a study of the austenitic grain score of 55PP steel after high-speed heating with external magnetization and conventional (slow) deep heating.

Fig. 8. Size distribution of γ-phase grains with HFC heating:

а — with an external magnetic field; б — without a field

Discussion. Changes in the kinetics of heating by high-frequency currents were observed when an external magnetic field was applied, the strength of which was sufficient for magnetic saturation. This effect led to a change in the magnetic properties of the processed steel, specifically, to a decrease in its magnetic permeability [13]. This behavior was natural for magnetization at the paraprocess stage; it, in turn, caused a decrease in k coefficient, which was inversely proportional to the depth of eddy current penetration and the specific thermal power. This can be compared to the increase in the current penetration depth into a metal during its transition from a ferromagnetic to a paramagnetic state. However, there is a physical difference in the nature of the paramagnetic state of a metal and the state of a ferromagnetic magnetized in the paraprocess region. They are similar only in terms of their small relative magnetic permeabilities. Thus, the presence of an external magnetic field at the stage of the first quasi-stationary process lead to a decrease in the rate of induction heating of the ferromagnetic material and an increase in the depth of its uniform heating.

The magnetic susceptibility drops sharply above the Curie point, so the external magnetic field does not affect the heating rate at these temperatures. At the same time, due to the small difference in magnetic permeability below and above the Curie point in the presence of an external field, there is no change in the heating curve that would indicate a transition of the surface layer to a paramagnetic state. In fields with higher intensities, the heating curve turns into a straight line (with the tangent of the angle of inclination to the time axis corresponding to the heating rate above the Curie point). A comparison of the dependencies in Figures 2 and 3 shows the similarity of the general patterns and confirms the validity of the earlier conclusions.

Regardless of the material used, in all the cases shown in Figure 3, the following patterns are observed: at the initial stage of heating, if an external magnetic field is applied, the heating rate decreases up to the Curie point. In the presence of an external magnetic field, the difference in the heating rate near the critical point in the diagram is less abrupt. At the end of the phase transformation, the heating rates with and without a field are practically compared.

As can be seen in Figure 4, the heating curves for conventional HFC heating and with the application of an external field converge as the wall thickness of the sample decreases, until they almost completely coincide for a thickness of 1 mm. This phenomenon can be explained by the fact that the wall thickness approaches the penetration depth of eddy currents in the absence of external magnetization.

Figure 5 clearly demonstrates that the influence of a magnetic field significantly reduces the temperature variation near the surface during the initial stages of heating. Without the use of a magnetic field, the variation is approximately 250 °C over the entire depth under study and about 50 °C from the surface to a point at a distance of 1 mm. However, after reaching the Curie point, the patterns of temperature distribution become similar, although there is a more significant decrease in surface temperature for the sample processed without applying an external field.

As can be seen in Figure 6, a similar pattern is observed in the 45 steel sample, with a greater uniformity of heating across the cross-section when an external magnetic field is applied up to the Curie point. When the surface layer of the sample heated in the field reaches the Curie temperature, the depth of current penetration into the material changes slightly (curves 3 and 4), since there is no sharp decrease in magnetic permeability. And in a sample that was heated without a field, after the transition to the paramagnetic state, the induced power is redistributed and heat is removed from the surface to the core, which causes a decrease in the temperature difference across the cross section. In this case (curve 4), the temperature distribution patterns turn out to be the same for both heating modes, but with greater uniformity of heating in the case of magnetization.

As shown by experiments with electric discharge (Fig. 7), it is not possible to harden the material to the desired depth without applying an external field. The hardening occurs at a maximum depth of 1 mm, with a hardened layer that is three times deeper. At the same time, electric discharge with magnetization allows for a greater depth of hardening, which can be achieved using the same setup. Additionally, the hardness achieved through electric tempering with magnetization is greater than that achieved through conventional furnace tempering.

Histograms of the distribution of austenite grain sizes after high-speed magnetization and conventional deep heating of steel with reduced hardenability show that, in the first case, the average grain diameter is 12.96 µm smaller (Fig. 8). Therefore, problems with austenite grain growth that occur during induction heating of steels with reduced hardenability can be avoided by using external magnetization.

Conclusion. The results of the study show that the application of an external magnetic field at temperatures below the Curie point increases the penetration depth of eddy currents, which, in turn, contributes to a more uniform heating of the material. This allows for the realization of hardening effects when heating at higher frequencies, eliminating the disadvantages of this type of heating that occur without magnetization. The observed changes in the presence of magnetization during heating of HFC are explained by a decrease in the magnetic permeability of the processed material, which is directly proportional to the depth of penetration of eddy currents. When the Curie point is reached, this effect levels off. It has been demonstrated that with the application of an external magnetic field, it becomes technologically possible to conduct high-speed electrical tempering on a single generator to achieve higher hardness values compared to conventional tempering. It is also recommended to use high-speed magnetization for HFC surface hardening of steels with reduced hardenability, as it eliminates the problem of coarse austenitic grains that can occur during conventional deep heating.

References

1. Pustovoit VN, Dolgachev YuV. Magnetic Heterogeneity of Austenite and Transformations in Steels. Rostov-on-Don: Don State Technical University; 2021. 198 p. (In Russ.)

2. Pustovoit VN, Dolgachev YV. Distortion-Free Heat Treatment of Thin Rods in Magnetic Field. Materials Performance and Characterization. 2018;7(6):20170159. https://doi.org/10.1520/MPC20170159

3. Pustovoit VN, Dolgachev YV, Dombrovskii YM. The Technology of Distortion-Free Quenching in a Magnetic Field of Thin-Walled Details of the Ring Form. Solid State Phenomena. 2021;316:233–239. https://doi.org/10.4028/www.scientific.net/SSP.316.233

4. Rudnev V, Loveless D, Cook RL. Handbook of Induction Heating. CRC press; 2017. 772 p.

5. Haimbaugh RE. Practical Induction Heat Treating, Second Edition. ASM International; 2015. 380 p.

6. Formalev VF. Heat Transfer in Anisotropic Solids. Numerical Methods, Heat Waves, Inverse Problems. Moscow: Fizmatlit; 2015. 274 p. (In Russ.)

7. Sergeev NN, Sergeev AN, Kutepov SN, Gvozdev AY, Chukanov AN, Ageeva EV. Influence of Heat Treatment on the Mechanical Properties of Rebar Products. Proceedings of the Southwest State University. Series: Engineering and Technology. 2021;11(2):8–25. (In Russ.) URL: https://techusgu.elpub.ru/jour/article/view/101 (accessed: 10.10.2025).

8. Kutepov SN, Gvozdev AE. Influence of Tempering Modes on the Mechanical and Corrosion Properties of Thermomechanically Hardened Rebar Rolled Products. In: Proceedings of the VIII International Scientific Conference “The Influence of Modernity on Science and Practice”. Madrid: Spain; 2021. 193 p. (In Russ.)

9. Gordienko AI, Gurchenko PS, Mikhlyuk AI, Vegera II. Processing of Mechanical Engineering Products Using Induction Heating. Minsk: Belorusskaya Nauka; 2009. 287 p. (In Russ.)

10. Lupi S. Induction Heating. Fundamentals of Electroheat: Electrical Technologies for Process Heating. Springer Cham; 2017. P. 353–524.

11. Kostukovich GA, Poprykailo AV, Auchynnikau YV, Verameichyk AI, Khvisevich VM, Linnik DA. Technology of Heat Treatment of Cardan Transmission Crosses by High-Frequency Currents. In: International Collection of Scientific Papers “Mechanics. Research and Innovation”. Vol. 17. Gomel: BelSUT; 2024. P. 77–84. (In Russ.)

12. Tsybulin IA. Analysis of Ways to Increase the Durability of Working Bodies of Tillage Implements and Substantiation of the Relevance of Further Study of the Hardening Process by Pulsed Electrocontact Heating. In: Proceedings of the International Scientific and Practical Conference Dedicated to the 100th Anniversary of the Department of Agricultural Machinery of the Faculty of Agricultural Engineering of Voronezh State Agrarian University named after Emperor Peter I. “Innovative Directions of Development of Technologies and Technical Means of Agricultural Mechanization”. Voronezh. December 25, 2015. Vol. 1, Part II. Voronezh: Voronezh State Agrarian University named after Emperor Peter the Great; 2015. pp. 333–339. (In Russ.)

13. Tumanski S. Handbook of Magnetic Measurements. CRC Press; 2016. 404 p. URL: https://books.google.ru/books?id=s0npF4E5jasC&hl=ru&num=15 (accessed: 09.11.2025).

About the Authors

V. N. PustovoitРоссия

Viktor N. Pustovoit, Dr. Sci. (Eng.), Professor of the Department of Materials Science and Technology of Metals

ElibraryID: 149062

ScopusID: 7006220091

1, Gagarin Sq., Rostov-on-Don, 344003

Yu. V. Dolgachev

Россия

Yuri V. Dolgachev, Dr. Sci. (Eng.), Associate Professor of the Department of Materials Science and Technology of Metals

ElibraryID: 617248

ScopusID: 55151183800

1, Gagarin Sq., Rostov-on-Don, 344003

A. S. Pivchenkov

Россия

Aleksey S. Pivchenkov, Master's Student of the Department of Materials Science and Technology of Metals

ElibraryID: 1219045

1, Gagarin Sq., Rostov-on-Don, 344003

The effect of an external magnetic field on the heating of iron carbon has been investigated. The paper demonstrates that the field increases the depth of penetration of eddy currents into the metal. Kinetic curves of heating and temperature distributions across the cross-section have been obtained. An improvement in the uniformity of heating and microhardness after treatment was found. The grinding of austenite grains during high-speed heating with an external field was demonstrated. The results are useful for improving the quenching and tempering processes of steel and cast iron components.

Review

For citations:

Pustovoit V.N., Dolgachev Yu.V., Pivchenkov A.S. Study of the Processes of Electric Heating Using High-Frequency Currents in a Magnetic Field. Safety of Technogenic and Natural Systems. 2025;9(4):331-340. https://doi.org/10.23947/2541-9129-2025-9-4-331-340. EDN: PLICAE

JATS XML