Scroll to:

Influence of the Magnetic Field on the Behavior of Cracks in Steel after Heat Treatment to a High-Strength State

https://doi.org/10.23947/2541-9129-2025-9-3-242-249

EDN: OIJHCO

Abstract

Introduction. Fatigue failure develops at stresses below the ultimate strength and is characterized by its suddenness and catastrophic consequences. Statistical data indicate that failure under cyclic loading is one of the common types of damage to materials and their performance is largely determined by their resistance to crack growth. In addition to well-known methods for achieving high-strength states, it has been proposed to use heat treatment in the magnetic field (HTMF). However, the mechanisms of crack behavior changes after such treatment and factors affecting crack resistance remain poorly understood. In this regard, this study aims to assess the effect of the structure after HTMF on the kinetic features of fatigue crack growth and the effectiveness of structural barriers formed during HTMF, preventing the destruction of steel.

Materials and Methods. The kinetics of fatigue crack development was studied during cyclic testing of prismatic samples using an original setup with a special stabilizer of oscillation amplitude. The occurrence and subsequent development of a crack was recorded by the method of electric potentials. The studies were conducted on steels that had been heat-treated to achieve a high-strength state: 18Kh2N4VA steel after quenching in air with a martensite structure and 30KhGSA steel after isothermal quenching at 380℃ to a lower bainite structure. A magnetic field of 1.6 MA/m was obtained in the magnetic gap of the FL-1 electromagnet.

Results. It was found that heat treatment of 30KhGSA and 18Kh2N4VA steels in a magnetic field of 1.6 MA/m led to a noticeable decrease in the rate of fatigue crack propagation. An increase in the threshold stress values for the delamination of the main crack by the tear-off mechanism was noted, which indicated an increase in durability. When analyzing the crack trajectories, an increase in their branching indicators was revealed: an increase in the standard deviation of crack inclination angles, as well as a decrease in the correlation interval of the crack bend inclination relative to the average position by 0.5 μm. These changes were due to the effect of the magnetic field on the microstructure of martensite, the formation of a greater number of effective barriers on the path of crack movement, which ultimately affected the resistance to fatigue failure of steels and their mechanical properties.

Discussion. Analysis of the obtained results, based on modern theories of strength and fracture, revealed that the mechanism of viscous destruction, which was typical for the steels under study, worked by the origin, growth and coalescence of pores. Under the influence of normal stresses, vacancies settled on the surface of micropores and as a result, the pore gradually transformed into a crack. Observations of cracks in foils showed that the change in the crack trajectory did not depend on the type of heat treatment and was a random process.

Conclusion. The statistical data obtained in this study allow us to conclude that after HTMF, a structure is formed that leads to an increase in the micro-tortuosity of cracks, with a steeper trajectory of bends due to frequent structural barriers. These features of crack behavior suggest that HTMF is a practical method for achieving a high-strength state in steels, which can be applied to a wide range of steel grades without requiring significant changes to their heat treatment processes. By increasing the crack resistance of steels, we can improve the safety of various devices and man-made systems, as well as reduce their costs and maintenance requirements.

For citations:

Pustovoit V.N., Dolgachev Yu.V. Influence of the Magnetic Field on the Behavior of Cracks in Steel after Heat Treatment to a High-Strength State. Safety of Technogenic and Natural Systems. 2025;9(3):242-249. https://doi.org/10.23947/2541-9129-2025-9-3-242-249. EDN: OIJHCO

Introduction. Destruction under cyclic loading is one of the most common types of damage to materials. The performance of these materials is largely determined by their resistance to crack growth. The problem is that cyclic loads can cause fatigue failure even at stresses below the ultimate strength of the material. Although the growth of a fatigue crack occurs gradually, the fracture itself can occur suddenly, leading to catastrophic consequences. There are extensive statistics [1] on railway and plane crashes, bridge collapses, and man-made accidents caused by the development of such defects. According to ASM International [2], up to 90% of mechanical failures in mechanical engineering are due to fatigue. In the oil and gas industry, billions of dollars are lost annually due to fatigue cracks in pipelines and drilling rigs. To address this issue, non-destructive defect control methods are introduced. These methods can account for up to 30% of maintenance costs in the aerospace industry. To ensure safe and long-term operation of machine parts and devices, it is essential to achieve their high-strength state with increased crack resistance.

Known methods of achieving a high-strength state [1, 2] involve combining a specific alloy composition with heat treatment methods, minimizing the presence of non-metal inclusions, creating a heterogeneous microstructure, and using surface hardening techniques. Previously, researchers have proposed a technology of heat treatment in a magnetic field (HTMF) [3], which allows for the creation of a high-strength state in steels under certain conditions. A feature of the proposed technology is an increase in strength characteristics without reducing viscosity. At the same time, widely used grades of alloy steels are subjected to almost traditional heat treatment modes, but with the application of permanent magnetic field energy.

Existing methods for increasing crack resistance [1, 2] operate by the following mechanisms: increasing the area of plastic deformation at the crack tip; branching the crack trajectory (increasing its path); creating compressive stresses to slow down crack growth; local hardening along the crack path; reducing the number and size of stress concentrators; creating microstructural barriers. However, there is still not enough information about how cracks behave in steels that have been treated with permanent magnetic fields. Therefore, the aim of this research is to investigate how the resistance to cracks and the rate of crack growth change after HTMF.

Materials and Methods. The features of crack development over time were studied using an installation that creates cyclic oscillations with stabilized amplitude. The design of this installation was described in [4]. The method of electric potentials [5, 6] made it possible to record the moment of origin and the stages of development of fatigue cracks. The data obtained in this way was transferred into real values using a calibration diagram that had known data on crack length and prismatic sample size.

The research results are presented in the form of dependencies with dl/dN – lg∆K axes [2, 7], characterizing the development of fatigue failure. The value of dl/dN ratio determines the exponential rate of crack propagation over a certain number of load cycles. Parameter ∆K demonstrates the range of variation of the stress intensity coefficient (SIC) under cyclic loads and is calculated as the difference between the highest and lowest SIC values:

(1)

(1)

values were calculated in terms of the maximum stresses (σ), that occur during cyclic bending of a prismatic sample with a crack of length l, according to the formula:

values were calculated in terms of the maximum stresses (σ), that occur during cyclic bending of a prismatic sample with a crack of length l, according to the formula:

(2)

(2)

Studies were conducted on prismatic samples of 18Kh2N4VA, 30KhGSA steels, which were heat-treated (18Kh2N4VA — air hardening for martensite; 30KhGSA — isothermal quenching at 38°C for lower bainite) for high-strength condition. A magnetic field with strength of 1.6 MA/m was in the magnetic gap of the FL – 1 electromagnet.

An Emma – 4 transmission electron microscope and a ZEISS CrossBeam 340 scanning electron microscope (SEM) were used to study the fine structure

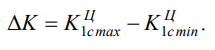

Results. Figure 1 illustrates the dependence of the fatigue crack length on the number of test cycles after various treatments for the studied steels.

Fig. 1. Dependence of fatigue crack growth on the number of cycles of alternating bending of steels: a — 30KhGSA; b — 18Kh2N4VA; solid line — processing without a field; dotted line — in a 1.6 MA/m magnetic field.

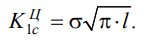

Diagrams of the development of fatigue cracks over time are presented in Figure 2. Their appearance illustrates the three stages of crack development. At each of these stages, the crack has a certain propagation velocity: 1st

stage — slow growth; 2nd stage — stable growth, and 3rd stage — accelerated or unstable growth [1]. Each of the stages is characterized by its own features of the fracture surface relief [2], which are well detected on the sample fracture after the cyclic bending test.

Fig. 2. Kinetic diagrams of fatigue crack development in steels: a — 30KhGSA; b — 18Kh2N4VA; solid line — processing without a field; dotted line — in a 1.6 MA/m magnetic field

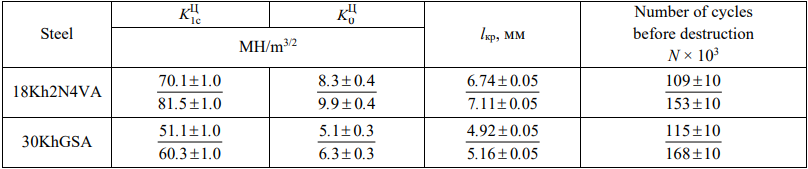

It can be seen (Fig. 2) that the crack propagation rate significantly decreases after HTMF compared to the treatment without a field, while the range of SIC ∆K values remains commensurate. The fracture of the sample occurs with a longer cyclic crack length and a larger value, as shown in Table 1. The numerator contains data for processing without a field, and the denominator contains data for processing in a field with a voltage of 1.6 MA/m. Confidence intervals are indicated with a confidence probability of P = 0.95 and the number of measurements n = 5.

Table 1

Parameters characterizing the viscosity during cyclic fracture

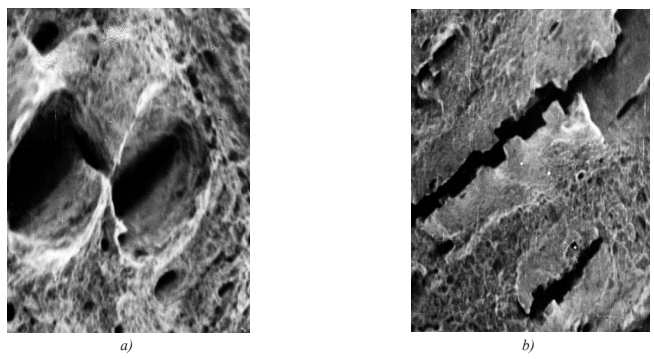

Figure 3 a illustrates the mechanism of viscous fracture by nucleation, growth, and coalescence of pores, which is typical for steels a18Kh2N4VA and 30KhGSA. Figure 3 b shows the result of how a crack forms from the pores under the influence of normal stresses.

Fig. 3. The mechanism of crack formation in 30KhGSA steel (SEM): a — fracture with pores (× 1,200); b — transformation of pores into a crack (× 500)

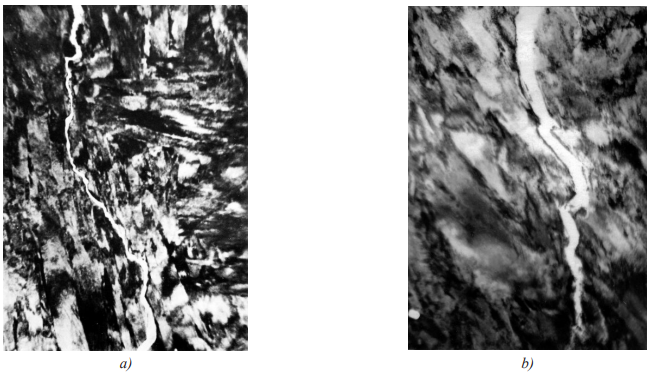

Figure 4 demonstrates the fragments of cracks under heat treatment conditions in a magnetic field and without a field. An analysis of such data was conducted to identify the dependence of the change in the crack trajectory on the type of heat treatment.

Fig. 4. Crack in the foil of 30KhGSA steel after quenching in oil (× 10,000): a — in a magnetic field; b — without a field

Discussion. The data in Figure 1 indicate that in the case of heat treatment in a magnetic field, the kinetics of crack propagation is more suppressed compared to treatment without a field, and the last stage of destruction occurs with a larger number of test cycles. Kinetic diagrams of fatigue crack development (Fig. 2) also demonstrate a significant decrease in the crack development rate under magnetic field treatment conditions while maintaining the SIC ∆K range. There are suggestions [8, 9] that in cyclic tests it is more expedient to characterize the viscosity by the initial (threshold) value of SIC, corresponding to the beginning of the separation of the main crack by a tear-off mechanism (with a given degree of constraint on plastic deformation), rather than by the maximum value of SIC corresponding to the limiting state. As can be seen from Table 1, the value increases after the HTMF. It is reasonable to anticipate an increase in the durability and operability of mechanical engineering products after heat treatment in a magnetic field [10, 11], which is also indicated by the results of previous studies on the effect of HTMF on mechanical properties [12, 13].

Monograph [3] summarizes the data that during processing to a high-strength state (the structure of upper martensite or lower bainite [14, 15]), the influence of a magnetic field manifests itself in significant fragmentation of the structure, increased dispersion of individual crystals of the ferromagnetic α-phase and their ensembles (packages), an increase in the specific surface area of the sub-boundaries that impede movement dislocations during loading. Local overstress at the tip of the dislocation cluster can relax through the formation of a crack nucleus, the development of which depends on the nature of the steel structure. Depending on the loading conditions and the initial state of the martensite [16, 17], the growth of a microscopic crack can occur by various mechanisms that determine the appearance of the fracture surface. It should be noted that for the 30KhGSA and 18Kh2N4VA steels under consideration, viscous fracture occurs when pores appear, grow, and combine (Fig. 3 a). Alternating loads lead to fatigue failure by forming a large number of excess vacancies (for example, as a result of inter-dislocation interactions and sliding with the formation of jogs [2, 18]), which can combine to form a pore. Normal stresses acting on the surface of the pore nuclei contribute to the vacancies sink, which leads to the transformation of the pores into a crack (Fig. 3 b).

The formed crack progress depends on the presence of obstacles in its path, which is determined by the features of the existing structure of the material. In this regard, the parameters of the crack propagation trajectory in thin foils were studied using electron microscopy, since they are very dependent on the structure [1]. The results of the fine structure analysis allow us to conclude that the use of HTMF technology does not affect the mechanism of changing the crack trajectory, i.e. the trajectory changes randomly (Fig. 4) when encountering various structural elements (carbides, phase boundaries, etc.) and does not depend on the method of heat treatment.

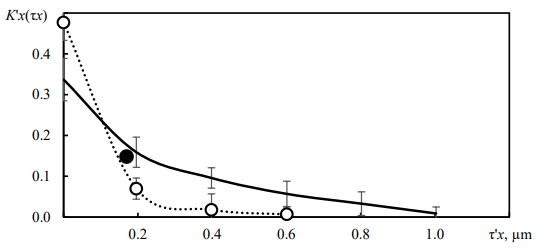

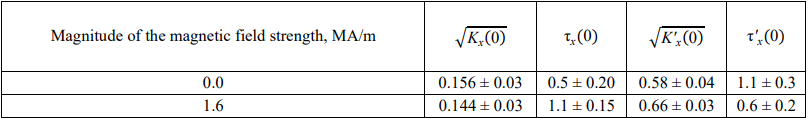

The autocorrelation functions analysis (AFA) [19, 20] linking the deviation of the crack line from its average position and the 1st derivative of its propagation trajectory (Fig. 5), which characterizes the angular parameters of the change in the trajectory of crack propagation in the foil, allows us to evaluate the effectiveness of the structural barriers caused by HTMF on the path of crack development. AFA allowed us to estimate the effect of HTMF on the statistical parameters of cracks:  — standard deviation of the crack line;

— standard deviation of the crack line;  — standard spread of the tangent of the trajectory angle (tortuosity index);

— standard spread of the tangent of the trajectory angle (tortuosity index);  — ranges of interdependence of the linear spread functions and slope tangents, respectively (they characterize an increase in crack length as a result of a single factor). The statistical parameters of cracks

— ranges of interdependence of the linear spread functions and slope tangents, respectively (they characterize an increase in crack length as a result of a single factor). The statistical parameters of cracks  for 30KhGSA steel are shown in Table 2. It shows the standard deviations of the experimental data.

for 30KhGSA steel are shown in Table 2. It shows the standard deviations of the experimental data.

Fig. 5. Graphs of autocorrelation functions of the slope of the bends of the crack line relative to the average position: solid line — processing without a field; dotted line — processing in a magnetic field with a strength of 1,6 МА/m

Table 2

Effect of heat treatment modes on the propagation parameters of a crack with a length of l = 6 µm

According to the data in Table 2, it can be noted that HTMF affects all the listed statistical characteristics of cracks. Standard tangent spread of the slope angles of the fracture line sections  after HTMF increases by 0.12, which corresponds to an increase in the average slope modulus of the crack trajectory by ~6° (from 29 to 35°). At the same time, correlation interval

after HTMF increases by 0.12, which corresponds to an increase in the average slope modulus of the crack trajectory by ~6° (from 29 to 35°). At the same time, correlation interval  decreases by 0.5 µm.

decreases by 0.5 µm.

Conclusion. The main result of this work is the identification of changes in the kinetics of fatigue crack development and the identification of mechanisms that contribute to increased crack resistance after HTMF. Based on the data obtained, it can be concluded that the technology of heat treatment in a magnetic field contributes to the formation of a structure that ensures an increase in the curvature of cracks. There is an increase in the steepness of the bending trajectory due to a greater number of effective barriers (an increase in the dispersion of martensite) in its path. In this respect, the nature of the HTMF's structure organization has much in common with the process of high-temperature thermomechanical treatment. This leads to the development of a new practical method for creating a high-strength state that can be applied to a wide range of steel grades without requiring significant changes to their heat treatment process. In turn, increasing the crack resistance of steels makes it possible to ensure greater safety of various devices and man-made systems, as well as reduce their cost and maintenance costs.

References

1. Gdoutos EE. Fracture Mechanics: An Introduction. Springer Nature Switzerland AG; 2020. 477 p.

2. Yukitaka Murakami. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions. Academic Press; 2019. 758 p.

3. Pustovoit VN, Dolgachev YuV. Magnetic Heterogeneity of Austenite and Transformations in Steels. Monograph. Rostov-on-Don: Don State Technical University; 2021. 198 p. (In Russ.)

4. Pustovoit VN, Grishin SA, Duka VV, Fedosov VV. Setup for Studying the Kinetics of Crack Growth in Cyclic Bending Tests. Industrial Laboratory. Diagnostics of Materials. 2020;86(7):59–64. (In Russ.) https://doi.org/10.26896/1028-6861-2020-86-7-59-64

5. Si Y, Rouse JP, Hyde CJ. Potential Difference Methods for Measuring Crack Growth: A Review. International Journal of Fatigue. 2020;136:105624. https://doi.org/10.1016/j.ijfatigue.2020.105624

6. Tarnowski KM, Dean DW, Nikbin KM, Davies CM. Predicting the Influence of Strain on Crack Length Measurements Performed Using the Potential Drop Method. Engineering Fracture Mechanics. 2017;182:635–657. https://doi.org/10.1016/j.engfracmech.2017.06.008

7. Zerbst U, Madia M, Vormwald M, Beier HTh. Fatigue Strength and Fracture Mechanics – A General Perspective. Engineering Fracture Mechanics. 2018;198:2–23. https://doi.org/10.1016/j.engfracmech.2017.04.030

8. Pineau A, McDowell DL, Busso EP, Antolovich SD. Failure of Metals II: Fatigue. Acta Materialia. 2016;107:484–507. https://doi.org/10.1016/j.actamat.2015.05.050

9. Tatsuo Sakai, Akiyoshi Nakagawa, Noriyasu Oguma, Yuki Nakamura, Akira Ueno, Shoichi Kikuchiet, et al. A review on fatigue fracture modes of structural metallic materials in very high cycle regime. International Journal of Fatigue. 2016;93(2):339–351. https://doi.org/10.1016/j.ijfatigue.2016.05.029

10. Schastlivtsev VM, Kaletina YuV, Fokina EA, Mirzaev DA. Effect of External Actions and a Magnetic Field on Martensitic Transformation in Steels and Alloys. Metal Science and Heat Treatment. 2016;58:247–253. https://doi.org/10.1007/s11041-016-9997-4

11. Yan Wang, Zhiguo Xing, Yanfei Huang, Weiling Guo, Jiajie Kang, Haidou Wang, et al. Effect of Pulse Magnetic Field Treatment on the Hardness of 20Cr2Ni4A Steel. Journal of Magnetism and Magnetic Materials. 2021;538:168248. https://doi.org/10.1016/j.jmmm.2021.168248

12. Pustovoyt VN, Dolgachev YuI. Structural State of Martensite and Retained Austenite in Carbon Steels after Quenching in Magnetic Field. Metallovedenie i Termicheskaya Obrabotka Metallov. 2022;(12(810)):10–14. (In Russ.) https://doi.org/10.30906/mitom.2022.12.10-14

13. Pustovoit VN, Dolgachev YV. Formation of Residual Stress Diagram after Quenching in a Magnetic Field. Safety of Technogenic and Natural Systems. 2024;8(4):54–61. https://doi.org/10.23947/2541-9129-2024-8-4-54-61

14. Bhadeshia HKDH, Honeycombe RWK. Steels: Structure, Properties, and Design. Elsevier; 2024. 550 p.

15. Fultz B. Phase Transitions in Materials. Cambridge University Press; 2020. 604 p.

16. Jinliang Wang, Xiaohui Xi, Yong Li, Chenchong Wang, Wei Xu. New Insights on Nucleation and Transformation Process in Temperature-Induced Martensitic Transformation. Materials Characterization. 2019;151:267–272. https://doi.org/10.1016/j.matchar.2019.03.023

17. Wang JL, Huang MH, Xi XH, Wang CC, Xu W. Characteristics of Nucleation and transformation sequence in Deformation-Induced Martensitic Transformation. Materials Characterization. 2020;163:110234. https://doi.org/10.1016/j.matchar.2020.110234

18. Anderson PM, Hirth JP, Lothe J. Theory of Dislocations. Cambridge University Press; 2017. 699 p.

19. Webster JG, Eren H (eds.). Measurement, Instrumentation, and Sensors Handbook: Two-Volume Set. CRC press; 2018. 3559 p.

20. Whitehouse DJ. Handbook of Surface Metrology. CRC press; 2023. 350 p.

About the Authors

V. N. PustovoitРоссия

Viktor N. Pustovoit - Dr. Sci. (Eng.), Professor, Professor of the Materials Science and Metal Technology Department, Don State Technical University.

1, Gagarin Sq., Rostov-on-Don, 344003

Scopus ID 7006220091

Yu. V. Dolgachev

Россия

Yuri V. Dolgachev - Dr. Sci. (Eng.), Associate Professor of the Materials Science and Metal Technology Department, Don State Technical University.

1, Gagarin Sq., Rostov-on-Don, 344003

Scopus ID 55151183800; ResearcherID B-2328-2016

Review

For citations:

Pustovoit V.N., Dolgachev Yu.V. Influence of the Magnetic Field on the Behavior of Cracks in Steel after Heat Treatment to a High-Strength State. Safety of Technogenic and Natural Systems. 2025;9(3):242-249. https://doi.org/10.23947/2541-9129-2025-9-3-242-249. EDN: OIJHCO

JATS XML