TECHNOSPHERE SAFETY

Introduction. Every year in the Russian Federation, approximately five thousand fires occur at production facilities, causing damage estimated in billions of rubles. To reduce the number of fires and minimize damage, work is underway to improve the methodology for calculating the number and equipment of fire protection units created to extinguish fires and conduct emergency rescue operations in organizations. This methodology was approved by Order of the Ministry of Emergency Situations of Russia dated October 15, 2021 No. 700 (hereinafter referred to as the Methodology). In the scientific literature on the analysis of fire hazards in industrial facilities in various sectors of the economy, there is a lack of a comprehensive indicator for fire hazard assessment of enterprises, which would take into account their technical and economic characteristics and industry affiliation. The aim of this study is to develop a dimensionless computing system describing the state of fire hazard of industrial facilities, taking into account their characteristic features. The developed complex was used in the formation of approaches to substantiate the number and technical equipment of facility-based fire protection units.

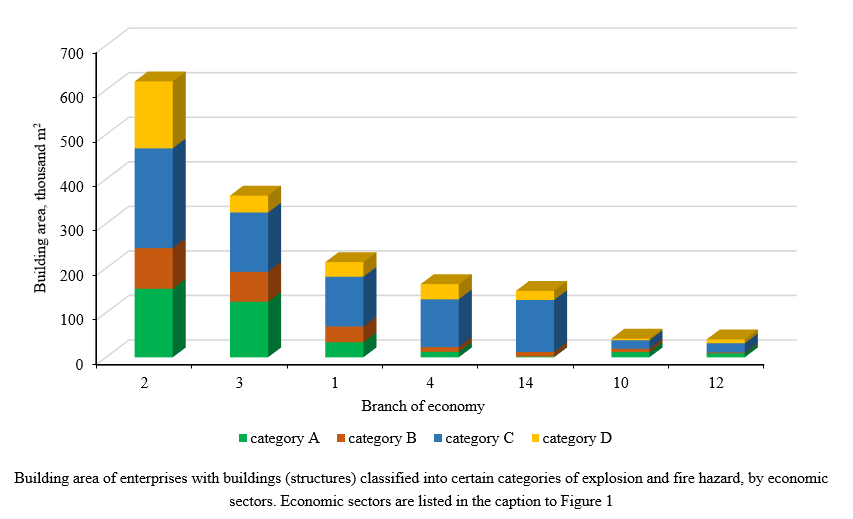

Materials and Methods. The analysis of statistical data on the number of fires, number of deaths and injuries, as well as the material damage caused by fires at production facilities in various economic sectors, was carried out using information from the Federal State Information System "Federal Database 'Fires'". To determine technical, economic and operational characteristics of enterprises with facility-based fire protection units, a survey was conducted using a questionnaire that collected information from 726 production facilities. Technical and economic characteristics of these facilities were studied, including: the area of land and buildings, number of employees, the mass of fire-hazardous, fire-explosive and explosive technological environments, the area of buildings and structures classified into certain categories of explosion and fire hazard, the number of fires at the enterprise, etc.

Results. A dimensionless Uпо computing system has been developed that characterizes the fire hazard level of industrial facilities. The distribution of values of the Uпо complex for production facilities where fire protection units have been established has been constructed, and the parameters of the resulting distribution have been determined. The criteria for classifying a production facility according to its fire hazard level have been established. The values of the fire hazard indicator for economic sectors have been calculated. Ferrous metallurgy (Uпо = 0.77), mechanical engineering and metalworking (0.73), non-ferrous metallurgy (0.70), and fuel industry (0.68) fell into the category of high fire hazard. The paper provides an example of calculating the fire hazard level for an electric power company.

Discussion. When determining the number and location of fire protection units, as well as the number of personnel and technical equipment, it is important to consider the level of fire risk at the production facility. An analysis of the distribution of values of the Uпо complex showed that it followed a normal distribution with an average value of m = 0.47 and a standard deviation of σ = 0.19. This meant that industries such as ferrous metallurgy and mechanical engineering had a higher level of fire risk compared to the electric power industry, which was classified as medium. The proposed method allows for an effective assessment of fire risk across different sectors of the economy.

Conclusion. The results obtained were used to develop a new version of the Methodology for calculating the number and technical equipment of fire protection units, created to extinguish fires and carry out emergency rescue operations in organizations. This methodology was approved by Order No. 700 of the Ministry of Emergency Situations of Russia dated October 15, 2021. The use of the developed complex will allow for a more accurate consideration of the specific characteristics of the production facility when determining fire protection resources.

Introduction. Environmental pollution with heavy metals is one of the most pressing environmental problems, as these substances can have a negative impact on ecosystems and living organisms. In particular, the accumulation of heavy metals in plants in urban ecosystems is an issue that has been widely studied, but many aspects of the problem remain unintelligible. For example, existing research does not always consider the influence of different environmental factors on metal sorption processes. This creates gaps in understanding the mechanisms of interaction between plants and pollutants. The current study aims to investigate the dependence of heavy metal sorption by the Scots pine (Pinus sylvestris) on the level of environmental pollution. The goal is to determine how metal accumulation indicators change depending on the growing conditions, allowing for a more accurate assessment of this plant's role in urban ecology.

Materials and Methods. The research was conducted in the city of Chita in the Trans-Baikal Territory. Scots pine is a widespread species of pine in this region, therefore, the bark of the Scots pine, as well as soil samples from sites in Chita that were exposed to high levels of human activity served as the basis for the study. Selection of sites was based, among other factors, on complex air pollution index (API5) in Chita. After collecting samples, they were quartered, dried, and ground into a fine powder. Then, the bark and soil were heated in a muffle furnace at 600°C. The burnt soil and pine bark ash were analyzed using methods commonly used in wood chemistry, including a spectrometric analysis on a Shimadzu AA-6200 atomic absorption spectrometer. The acidity was determined by the potentiometric method in a chloride extract. For this purpose, a 1M KCl solution (pH = 6.0) was used, as well as standard buffer solutions (pH 4.01; 6.86; 9.18) for instrument calibration. Suspensions were prepared by adding 75 ml of extractant to 30 g of soil, stirring for one minute. The pH was then measured after the readings stabilized. In parallel, a control experiment was conducted without a soil sample.

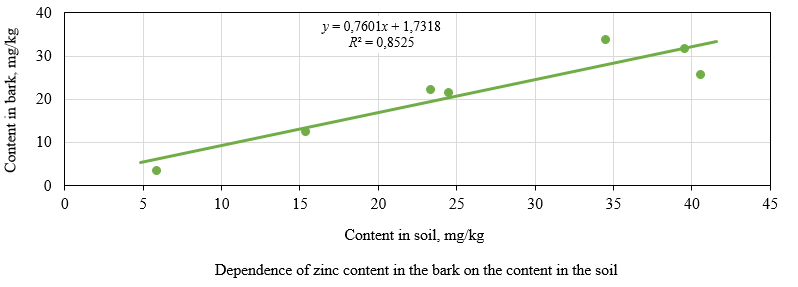

Results. Analysis of the data on seasonal changes in the ash and moisture content of Scots pine bark showed that they slightly increased in the summer and autumn months. During the study, we also obtained data on the distribution of heavy metals in the soil and bark of Scots pine depending on the season of the year. It was found that the highest levels of copper in the soil and bark of Scots pine were observed in Batareinaya Sopka, exceeding the maximum permissible concentration by 11 times, followed by Granitnaya Street, where the maximum permissible concentration was exceeded by 5 times. Zinc levels in the soil were high at three locations: Sosnovy Bor, Memory Park, and Batareinaya Sopka, exceeding the maximum permissible concentration by 1.77, 1.74 and 1.5 times, respectively. Lead levels were within the MPC at all seven locations. There were no seasonal changes in the content of heavy metals in the soil and bark. Thus, the study revealed the dependence of the content of heavy metals in the soil and bark of the Scots pine on the degree of anthropogenic load in the districts of Chita in the Trans-Baikal Territory.

Discussion. The results of the study demonstrated the correlation between the concentration of heavy metals in soil and bark samples of Scots pine and the degree of anthropogenic load. Therefore, the Scots pine can be considered a valuable object for monitoring heavy metal pollution, as it combines high sensitivity to man-made effects, resistance to adverse conditions and long-term ability to accumulate toxic substances. The data obtained support the idea of including the Scots pine in environmental monitoring systems, particularly in areas with developed industrial and transportation infrastructure. Future research could focus on developing standardized methods for using pine in bioindication, as well as studying its phytoremediation potential in conditions of chronic pollution.

Conclusion. The study expands our understanding of the mechanisms behind the migration and accumulation of heavy metals in urban ecosystems, especially in areas with a harsh continental climate. The findings can be used to improve urban planning, reduce the negative impact on public health, and develop sustainable strategies for areas with high levels of anthropogenic load.

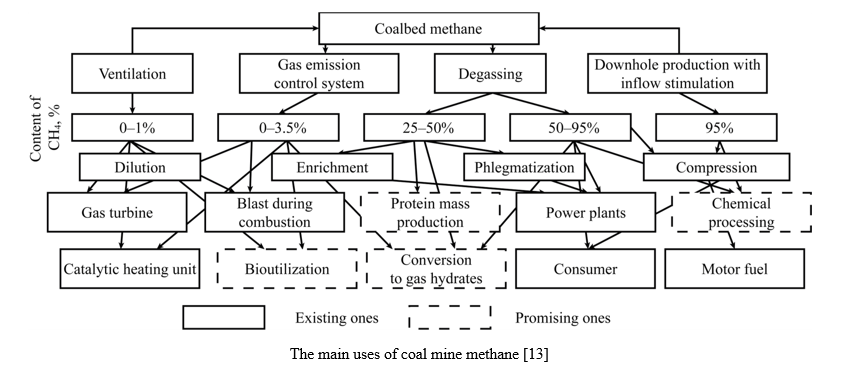

Introduction. Coal mine methane, a greenhouse gas released during underground coal mining, is considered to be a cause of global climate change. However it is also a valuable energy resource. Currently, the global utilization rate of coal mine methane is low, and the amount of methane released into the atmosphere is increasing every year. To limit greenhouse gas emissions, several legislative initiatives have been implemented, including the Kyoto Protocol, the Paris Agreement, and Federal Law No. 296-FZ “On Limiting Greenhouse Gas Emissions”. In the conditions of Donbass, the task of mine methane utilization is relevant due to the dense location of emission sources and the need to improve the safety of mining operations, as well as to ensure the implementation of the principle of integrated field development. In addition, the ongoing hostilities have led to an increase in fuel prices in the region and an increase in road transport due to the limited availability of rail, sea, and air transportation. The aim of the research is to conduct a calculated assessment of the energy efficiency of using mine methane from Donbass coal deposits as motor fuel for commercial vehicles with internal combustion engines.

Materials and Methods. As an example, the studies were conducted on BAZ-2215 vehicles on the GAZelle Business chassis, GAZelle Next Citiline, and PAZ 3203, which were commonly used on urban routes in Makeyevka (DPR). These vehicles were equipped with UMZ, ZMZ, and Cummins spark and diesel engines. The full composition of methane-air mixture samples from several mines (Chaykino Mine, Makeyevka, Komsomolets Donbassa Mine, Kirovskoye), taken from degassing systems, was determined in the laboratories of Makeevka Research Institute for Mining Safety and Donetskavtogaz using a Kristallyuks 4000M gas chromatograph. The energy efficiency of engines operating on various types of fuel, including mine methane, as well as the performance characteristics of selected buses (fuel consumption, distance-to-empty, and carbon dioxide emissions) under urban driving cycles according to GOST R 54810–2011, were determined through a series of calculations using well-established methods.

Results. An estimation of the energy efficiency of mine methane as a gas engine fuel has been performed. In the range of concentrations of the studied samples of gas-air mixtures, the calculated maximum loss of effective power for ZMZ and UMZ spark engines was up to 15%. For gas-diesel engines, such as Cummins, power could be increased by up to 29%. These findings did not prevent selected buses from operating under driving cycles in accordance with GOST R 54810–2011. Under these conditions, fuel consumption and range per refueling depended significantly on the component composition of mine methane. For the samples studied, it was 1.8–3.5 times worse than for natural gas used for refueling. Emissions of carbon dioxide were reduced by 62–73% compared to gasoline.

Discussion. Due to the specific features of degassing processes and the mining and geological conditions of different mines, the alternative fuel discussed in this article has a variable component composition. In this regard, the transfer of PAZ and GAZ bus rolling stock to a byproduct of coal mining — mine methane — is associated with several challenges. These include the need for more powerful fuel systems (three times or more than the power supply systems of internal combustion engines of comparable power, operating on compressed gas) and deterioration in fuel-economic and traction-speed properties of vehicles, as well as reduced range. A quantitative assessment of these changes has been obtained through research. The positive impact of the proposed measures stems from the reduction in negative environmental impact by using mine methane as a fuel for vehicles, which reduces the carbon footprint of road transport and decreases the consumption of liquid hydrocarbon fuel.

Conclusion. As a result of the study, it has been found that the methane from the Donbass coal mines can be used as motor fuel for commercial vehicles such as city buses. The study has determined the corresponding energy efficiency parameters (the effective power generated by internal combustion engines, the specific fuel consumption, the range of vehicles under driving cycles, etc.), as well as the degree of their reduction compared to traditional fuels. It has been established that this does not affect the performance of transportation work (in compliance with GOST R 54810–2011) and is beneficial from the perspective of saving non-renewable resources and improving environmental safety in the region.

CHEMICAL TECHNOLOGIES, MATERIALS SCIENCES, METALLURGY

Introduction. Modern materials require a deep understanding of their structure in order to predict their performance properties. However, the use of various imaging techniques and programs, such as optical and electron microscopy, is limited to two-dimensional images, making it difficult to fully analyze the morphology of materials. Despite research in this field, there is still a lack of knowledge about the three-dimensional organization of materials, leading to gaps in our understanding of how geometry affects the physical properties of composite materials. ImageJ was chosen for this study due to its versatility and ability to support multiple formats, simplifying the process of analysis. It also offers powerful tools for automated processing and allows users to extract three-dimensional information from two-dimensional images. This is crucial for accurately identifying structural components. The current study aims to fill in the missing information by analyzing the morphology of a steel ferrite-martensite composite. The aim of the work is to determine the 3D surface structure of the composite, which will improve understanding of its performance characteristics and confirm the significance of selecting appropriate visualization techniques.

Materials and Methods. An image of the microstructure of a steel natural ferrite-martensitic composite (NFMC), obtained using a Metam PB–22 optical microscope, was chosen as the starting material for analysis. The microstructure in question consists of two phases: the light phase being ferrite and the dark phase being martensite. The ImageJ program, which has been adapted to various formats of electron microscopic and metallographic images, was used to obtain a wide range of geometric characteristics of the surface.

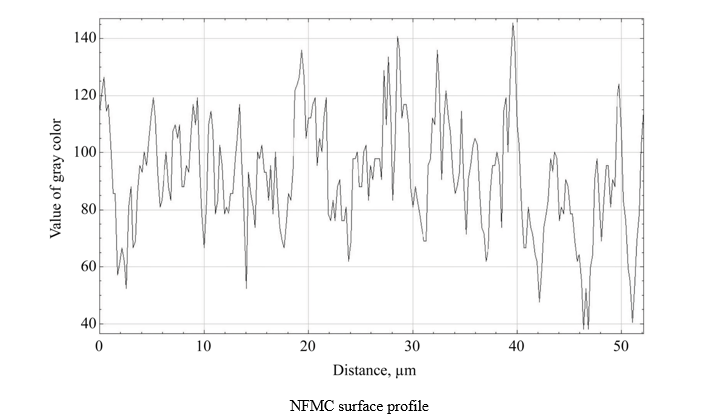

Results. A study using ImageJ software on the microstructure of a steel ferrite-martensitic composite revealed a characteristic lineage structure consisting of a light phase (ferrite) and a dark phase (martensite). Image processing, including scaling and segmentation, led to the conversion to black and white format, allowing for clear visualization of the boundaries between the phases and the geometric shapes of the particles. The four-parameter Rodbard calibration function provided additional data on area, standard deviation, skewness, and kurtosis, making it difficult to analyze the structure. As a result, ferrite occupied 40.8% of the area, while martensite occupied 59.2%. The surface profile revealed an alternating pattern of misoriented crystals, and the quantitative information allowed for the creation of a clear 3D image of the composite surface.

Discussion. The thickness of grain boundaries in pixels was found to be thinner in this graphic editor than in others, which affected the area and, consequently, the amount of light phase. The change in the quantitative ratio of ferrite-martensite phases was due to the program's ability to suppress image “noise” and more clearly read the unrecognized gray phase, with some of it belonging to the light phase and some to the dark phase.

With the advancement of technology and the increasing demands for strength and wear resistance, understanding the microstructure of materials has become crucial for optimizing their properties. The selection of appropriate imaging techniques, such as the use of ImageJ software, not only allows for accurate data on phase distribution, but also contributes to a more in-depth analysis of mechanical properties such as hardness and corrosion resistance. These aspects are important in the context of the development of innovative technologies where reliability and durability are essential factors.

Conclusion. The use of the ImageJ software package for visualization in 2D and 3D graphics and qualitative and quantitative analysis of the surface morphology of heterogeneous structural states of materials is a convenient, effective and informative way to obtain geometric characteristics of particles of structural components. It is also possible to map the shape and size of particles. Automation of this process leads to time and resource savings, minimizing the influence of subjective factors on results at different stages of analysis. Identification of the 3D surface structure of composites helps to deepen our understanding of their operational characteristics, which is crucial in the context of modern technological demands. This knowledge allows us to develop new materials with improved properties such as strength, wear and corrosion resistance. Furthermore, it enables us to predict how materials will perform in actual conditions.

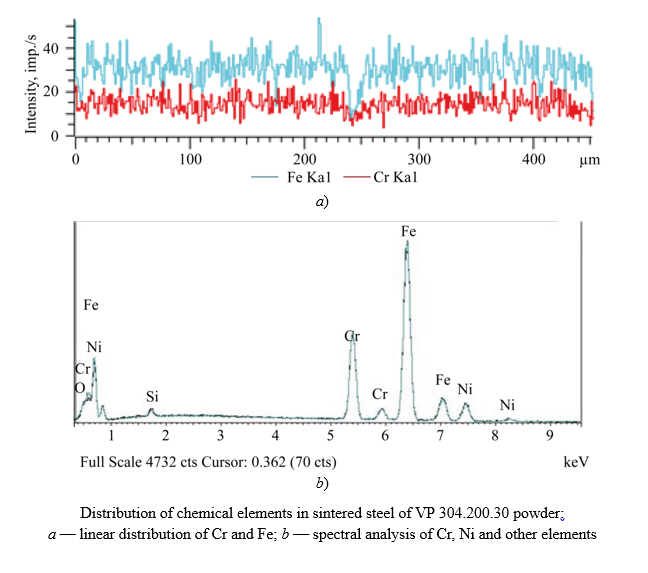

Introduction. Investigating the issues of wear resistance of joints, the authors of this paper have previously studied how the features of chromium-nickel corrosion resistant steels affect the shaping of the outer cage of spherical hinges. They sintered compacts made of 12Kh18N10T, VP 304.200.30 and 304L-AW-100 at 1,200°C in vacuum for 3 hours. However, in practice, it is necessary to test different steels in different conditions. This paper describes 10Kh18N9 rolled stainless steel. Powder VP 304.200.30 was sintered at 1,150°C for 2 hours. The aim of the research is to demonstrate how the production method and the metal structure affect the kinetics of the outer cage formation and, consequently, the strength of the product.

Materials and Methods. Samples made of 10Kh18N9 and VP 304.200.30 were radially compressed according to GOST 26529–85 and stretched on an UMM-5 testing machine. Hardness was measured using a Rockwell TP 5006 instrument, and microhardness was measured according to Vickers on an HVS-1000 instrument. X-ray phase analysis was performed on an XRD-6100 diffractometer. Microscopes Tescan VEGA II LMU (for electron probe studies), Quanta 200 and Altami MET-1M (for studying microstructure and metallography) were used. Cold stamping of the outer cage with a spherical hinge flange was modeled in QForm.

Results. The strength and yield strength of VP 304.200.30 were comparable to those of some chromium-nickel austenitic steels, but were inferior in terms of ductility. A comparison between 10Kh18N9 and VP 304.200.30 revealed differences in their deformation mechanisms. The critical limitation for powder steel was not the oxide phase, but the localization of oxides at particle boundaries, which provoked brittle fracture under tension. Due to the chemical heterogeneity in the particles and residual porosity, powder steel had a 6-fold lower elongation compared to rolled steel. However, under compression conditions, sintered material could reach a hardness of 195 HV, making it suitable for use in the outer cage of spherical hinges.

Discussion. Analysis of the deformation characteristics of sintered and rolled steels confirmed the suitability of the proposed methodology for assessing the deformation state of samples during cold stamping of the outer cage of spherical hinges.

Conclusion. The findings from this study allow us to predict the locations of macrodefects and optimize the manufacturing process for spherical hinges.

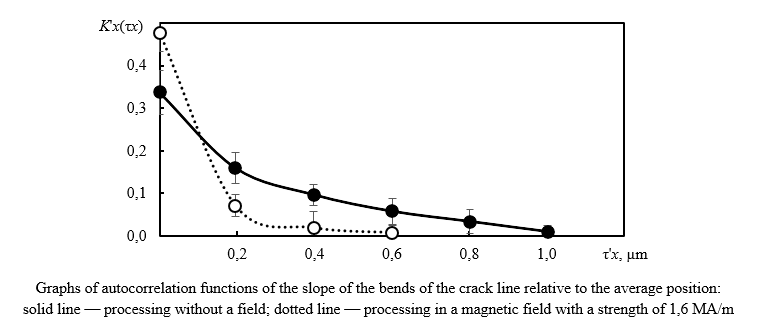

Introduction. Fatigue failure develops at stresses below the ultimate strength and is characterized by its suddenness and catastrophic consequences. Statistical data indicate that failure under cyclic loading is one of the common types of damage to materials and their performance is largely determined by their resistance to crack growth. In addition to well-known methods for achieving high-strength states, it has been proposed to use heat treatment in the magnetic field (HTMF). However, the mechanisms of crack behavior changes after such treatment and factors affecting crack resistance remain poorly understood. In this regard, this study aims to assess the effect of the structure after HTMF on the kinetic features of fatigue crack growth and the effectiveness of structural barriers formed during HTMF, preventing the destruction of steel.

Materials and Methods. The kinetics of fatigue crack development was studied during cyclic testing of prismatic samples using an original setup with a special stabilizer of oscillation amplitude. The occurrence and subsequent development of a crack was recorded by the method of electric potentials. The studies were conducted on steels that had been heat-treated to achieve a high-strength state: 18Kh2N4VA steel after quenching in air with a martensite structure and 30KhGSA steel after isothermal quenching at 380℃ to a lower bainite structure. A magnetic field of 1.6 MA/m was obtained in the magnetic gap of the FL-1 electromagnet.

Results. It was found that heat treatment of 30KhGSA and 18Kh2N4VA steels in a magnetic field of 1.6 MA/m led to a noticeable decrease in the rate of fatigue crack propagation. An increase in the threshold stress values for the delamination of the main crack by the tear-off mechanism was noted, which indicated an increase in durability. When analyzing the crack trajectories, an increase in their branching indicators was revealed: an increase in the standard deviation of crack inclination angles, as well as a decrease in the correlation interval of the crack bend inclination relative to the average position by 0.5 μm. These changes were due to the effect of the magnetic field on the microstructure of martensite, the formation of a greater number of effective barriers on the path of crack movement, which ultimately affected the resistance to fatigue failure of steels and their mechanical properties.

Discussion. Analysis of the obtained results, based on modern theories of strength and fracture, revealed that the mechanism of viscous destruction, which was typical for the steels under study, worked by the origin, growth and coalescence of pores. Under the influence of normal stresses, vacancies settled on the surface of micropores and as a result, the pore gradually transformed into a crack. Observations of cracks in foils showed that the change in the crack trajectory did not depend on the type of heat treatment and was a random process.

Conclusion. The statistical data obtained in this study allow us to conclude that after HTMF, a structure is formed that leads to an increase in the micro-tortuosity of cracks, with a steeper trajectory of bends due to frequent structural barriers. These features of crack behavior suggest that HTMF is a practical method for achieving a high-strength state in steels, which can be applied to a wide range of steel grades without requiring significant changes to their heat treatment processes. By increasing the crack resistance of steels, we can improve the safety of various devices and man-made systems, as well as reduce their costs and maintenance requirements.

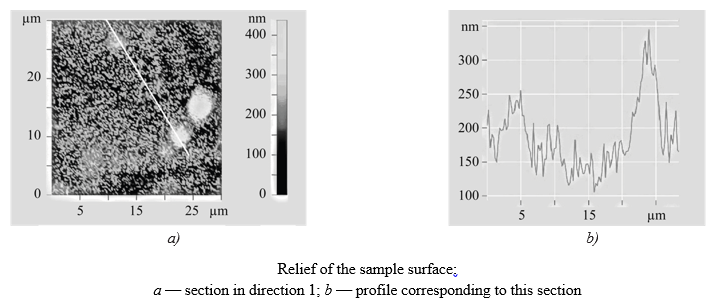

Introduction. In modern production, it is important to increase reliability and durability of steel products. One way to achieve this is by creating high-hardness, wear-resistant coatings on their surface. These coatings can be formed using the method of diffusion saturation, which involves the introduction of carbide-forming elements into the metal. Traditional methods for creating these coatings are time-consuming, taking up to 8 hours or more. To accelerate this process, researchers have proposed using high-energy methods such as laser and plasma treatments. However, these methods require specialized equipment that can be expensive. In this paper, we consider a method for creating a high-hardness molybdenum-based coating by microarc alloying. This method involves exposing a processed steel product immersed in coal powder to multiplicative microarc discharges that occur between the metal surface and the surrounding powder medium. The discharges are generated when an electric current is passed through them. This method allows for a significant increase in the process of diffusive surface saturation. It is characterized by simplicity and low energy consumption. The properties of the resulting coatings are primarily determined by their fine structure. Therefore, studying this structure is a crucial task. The aim of this research was to investigate the features of the fine structure of the steel surface layer after microarc molybdenum plating.

Materials and Methods. A coating containing finely dispersed ammonium molybdate powder and an electrically conductive gel as a binder in a volume ratio of 1:1 was used as a source of molybdenum for diffusion saturation. The coating was applied to the surface of cylindrical samples made of 20 steel with a diameter of 12 mm and a length of 35 mm. Then they were immersed in a metal container with a carbon powder with a particle size 0.4–0.6 mm. An electric current was passed through this powder for 6 minutes, with a surface current density of 0.53 A/cm2. A Neophot-21 microscope, an ARL X'TRA-435 diffractometer, a ZEISS CrossBeam 340 scanning electron microscope with an X-ray microanalyzer, and a NanoEducator scanning probe microscope were used to study the fine structure of steel.

Results. After microarc molybdenum saturation of steel samples, a coating with a multilayer structure and a complex phase composition was formed. On the surface of the material, there was a slightly etched layer with a thickness of 50–55 µm, under which there was a carbonized layer with eutectoid structure and a thickness of approximately 200 µm, and the original ferrite-pearlite structure was preserved lower. The base of the slightly etched layer was a dispersed ferrite-carbide mixture containing about 47% wt. % of Mo and having a microhardness of 8–9 GPa. This layer contained carbide inclusions up to 5 µm in size, containing 94 wt. % of Mo and having microhardness up to 21 GPa. The surface relief was characterized by the presence of carbide inclusions of 3–5 µm in size, as well as multiple nanoscale inclusions protruding above the surface to a height of 10 to 150–200 nm.

Discussion. The results of the study, obtained using metallographic analysis, scanning electron microscopy, X-ray phase analysis and atomic force microscopy, showed that during microarc molybdenum steel saturation, a diffusion layer was formed containing nanoscale particles of the carbide phase. These particles reached a volume fraction of up to 70% and were located at the base of the layer. This layer was a ferrite-carbide eutectoid mixture. A quantitative assessment of the strengthening effect of these particles confirmed that the presence of such particles, characterized by high microhardness, determines the high hardness of the resulting coating.

Conclusion. Microarc molybdenum steel saturation is an effective method for creating coatings with exceptional performance characteristics. These coatings are characterized not only by their high hardness, due to the presence of nanoscale carbide particles located in a ferrite-carbide base, but also by their improved mechanical properties. This makes them promising for use in various industries where high wear resistance and durability of products are required. The research findings indicate that microarc molybdenum steel saturation significantly reduces processing time and avoids the use of expensive equipment, which makes it more affordable for industrial implementation.